An energy-saving grain dryer

A grain dryer, energy-saving technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve problems such as small output and achieve the effect of preventing overloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

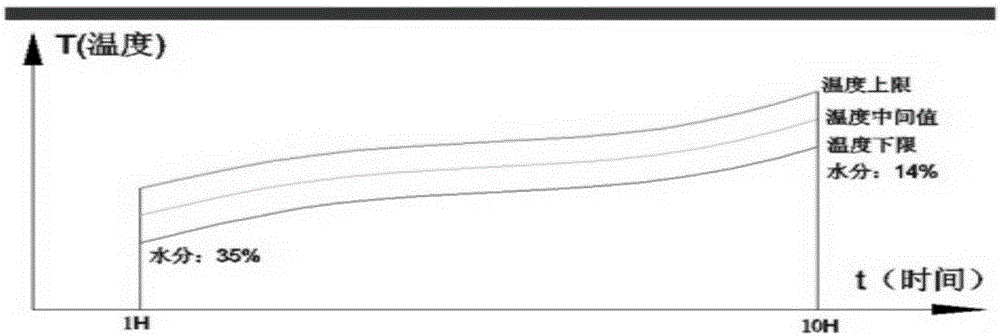

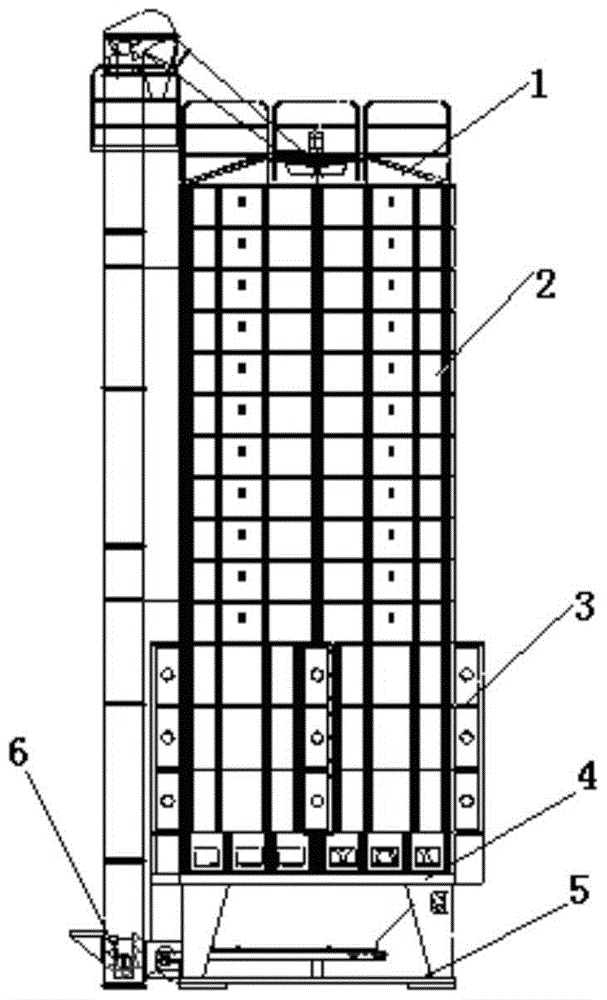

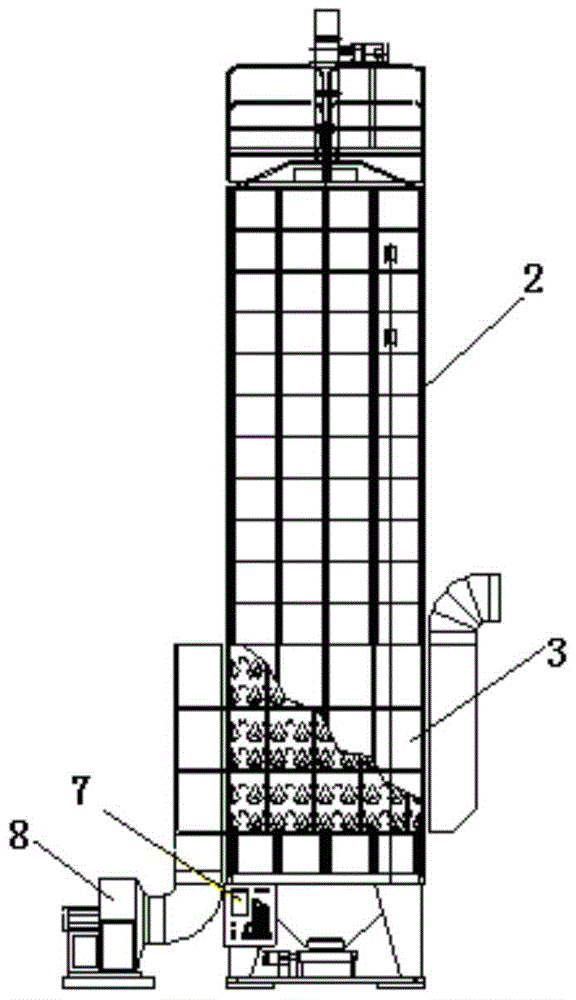

[0024] Referring to the accompanying drawings, an energy-saving grain dryer includes a top cover 1, a slowing warehouse 2, a drying layer 3, a grain discharge layer 4, a main engine bottom 5, a hoist 6, a control system 7, an exhaust fan 8, and a top cover 1 There is a grain spreading mechanism inside, and the grain spreading mechanism includes a grain feeding hopper 9, a grain spreading disc 10, and a grain spreading blade 11. The grain spreading blade 11 is installed on a rotating shaft 12, and the upper end of the rotating shaft 12 is fixedly connected with a motor 13, and the rotating shaft A shaft cover 14 is installed at the lower end of 12, and the grain spreading blade 11 is perpendicular to the material spreading disc 10. One end of the grain spreading blade 11 extends to the spreading material disc 10, and the other end is close to the shaft cover 14, and a screw is passed between the rotating shaft and the grain spreading disc. Tightly connected, the grain spreading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com