Tibia base element and knee joint prosthesis

A technology of knee joint prosthesis and base, which is applied in the field of knee joint prosthesis, can solve problems such as easy loosening or damage, ligament wear, and anterior cruciate ligament rupture, so as to prevent ligament prolapse, reduce bone requirements, Applicable to a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0044] In the present invention, the so-called "front", "rear", "upper" and "lower" directions are consistent with the front, rear, upper and lower directions when a person stands after the knee joint prosthesis is implanted into the human body, and the present invention The left leg knee prosthesis is used as an example for description.

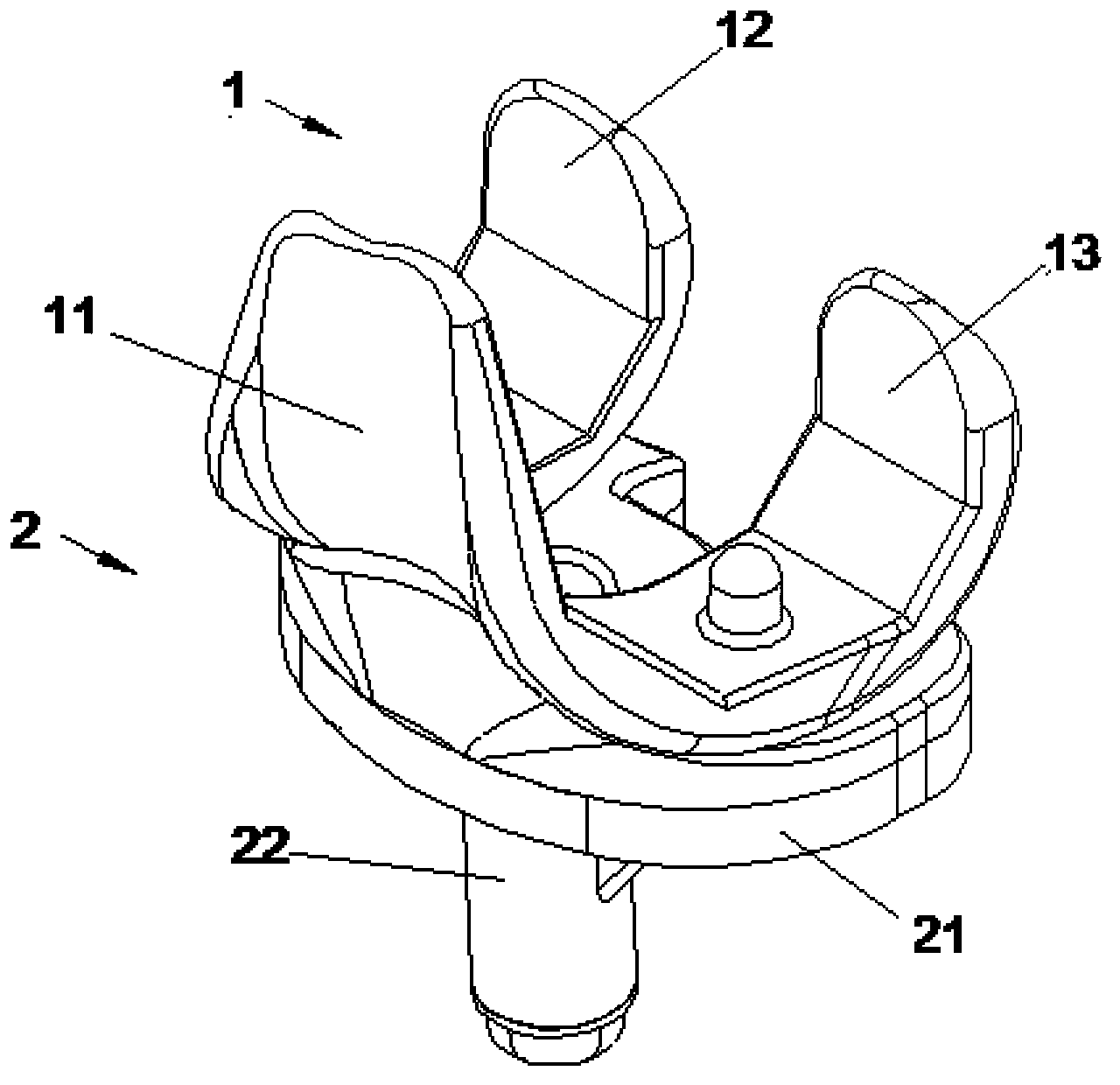

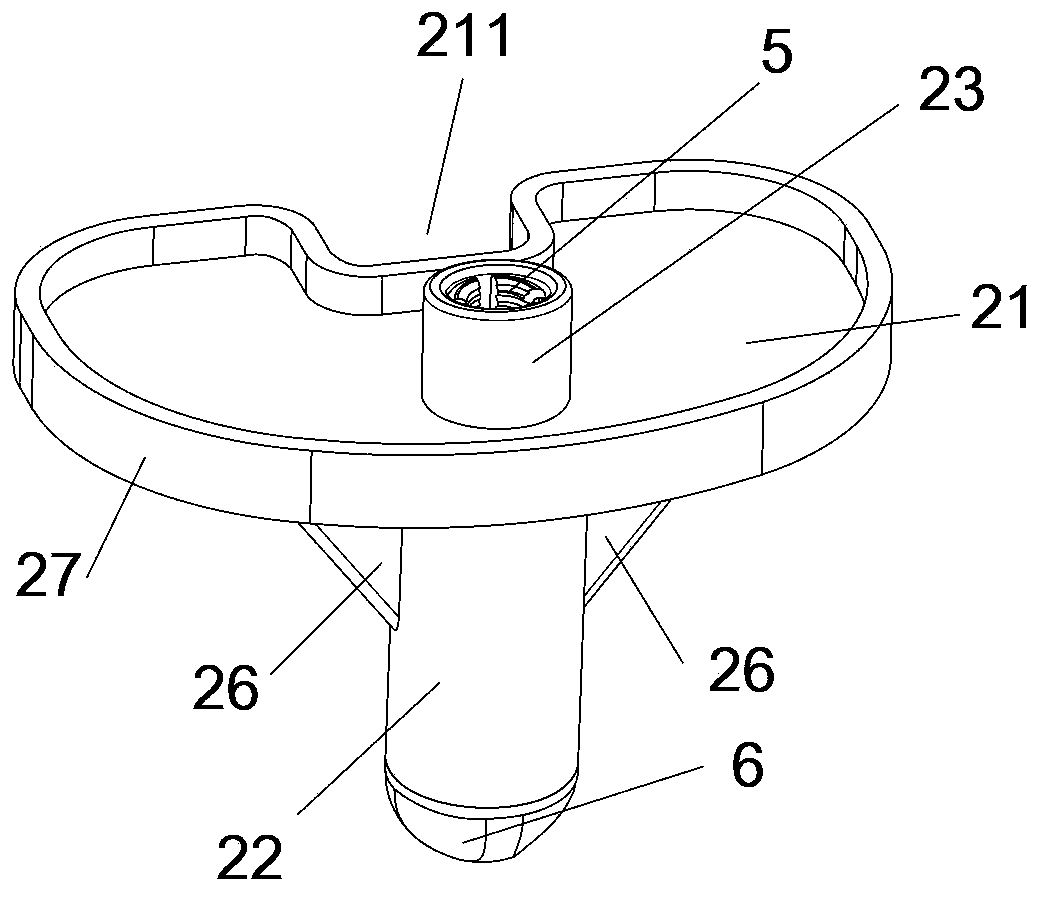

[0045] Such as figure 1 As shown, the knee joint prosthesis of the present invention includes a femoral component 1 , a tibial base component 2 , and a liner 3 .

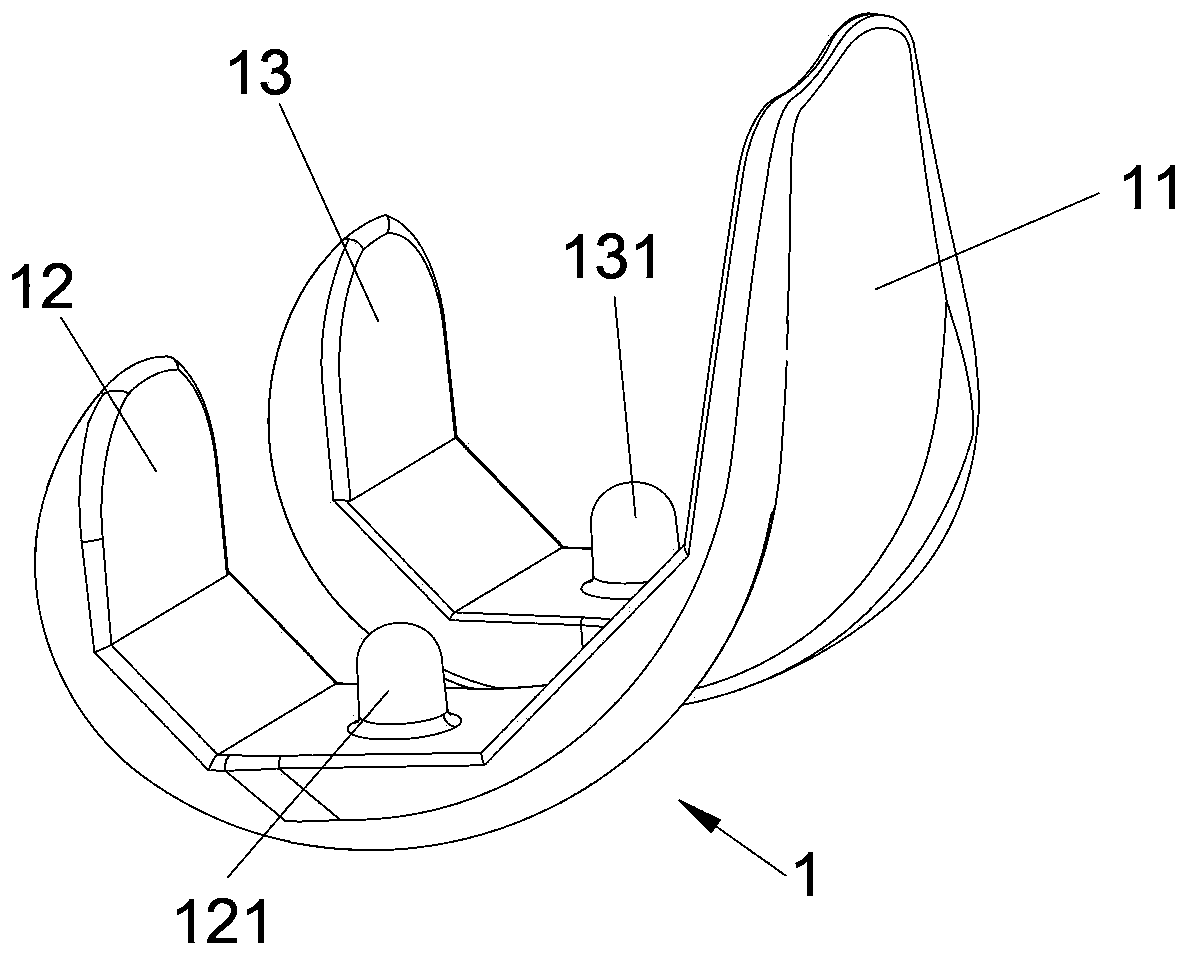

[0046] Such as figure 2 As shown, the femoral component 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com