Intervertebral filling fusion device

A fusion device and intervertebral technology, applied in medical science, prostheses, spinal implants, etc., can solve the problems of cumbersome operation, easy collapse, and inability to form good spinal bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

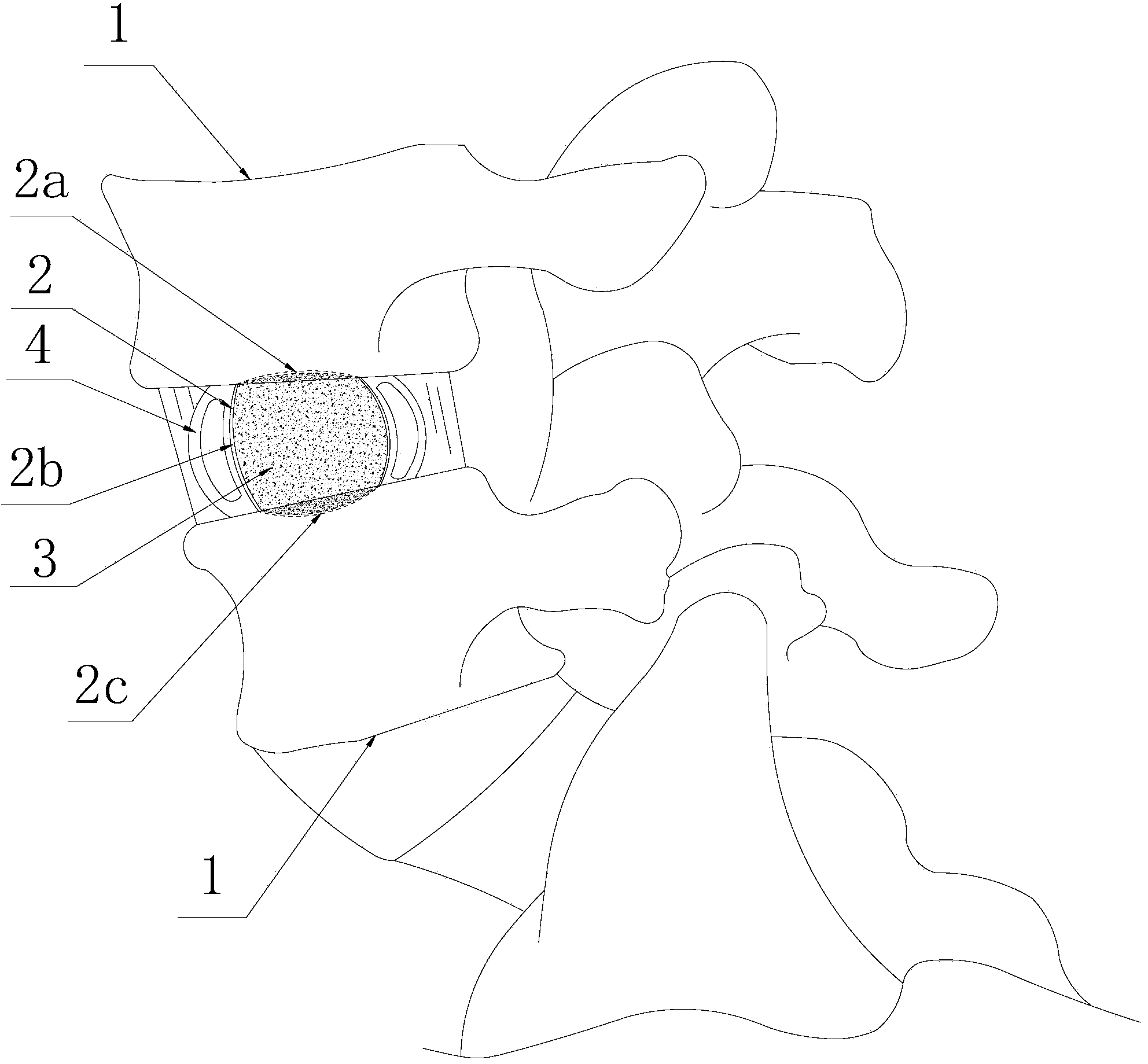

[0030] Example 1: Combining figure 1 Shown is a specific embodiment of the intervertebral filling and fusion device of the present invention, which is used to fill between any two adjacent vertebral body endplates 1 of the human lumbar spine. The device has a bag-shaped container 2, and the bag The pouch-shaped container 2 is composed of an enclosure 2b and a top surface 2a connected to the enclosure 2b and a bottom surface 2c. Fitting filler 3, said filler 3 is taken from body bone or allograft bone. An annular airbag 4 is placed outside the bag-shaped container 2 to surround the circle 2 b to support the upper and lower vertebral body endplates 1 and support the inner filler 3 .

[0031] In this embodiment, the bag-like container 2 is a net body woven from high-strength polyethylene fibers, wherein the weaving density of the circle 2b is greater than that of the top surface 2a and the bottom surface 2c, so that the supporting strength of the circle 2b is greater than that o...

Embodiment 2

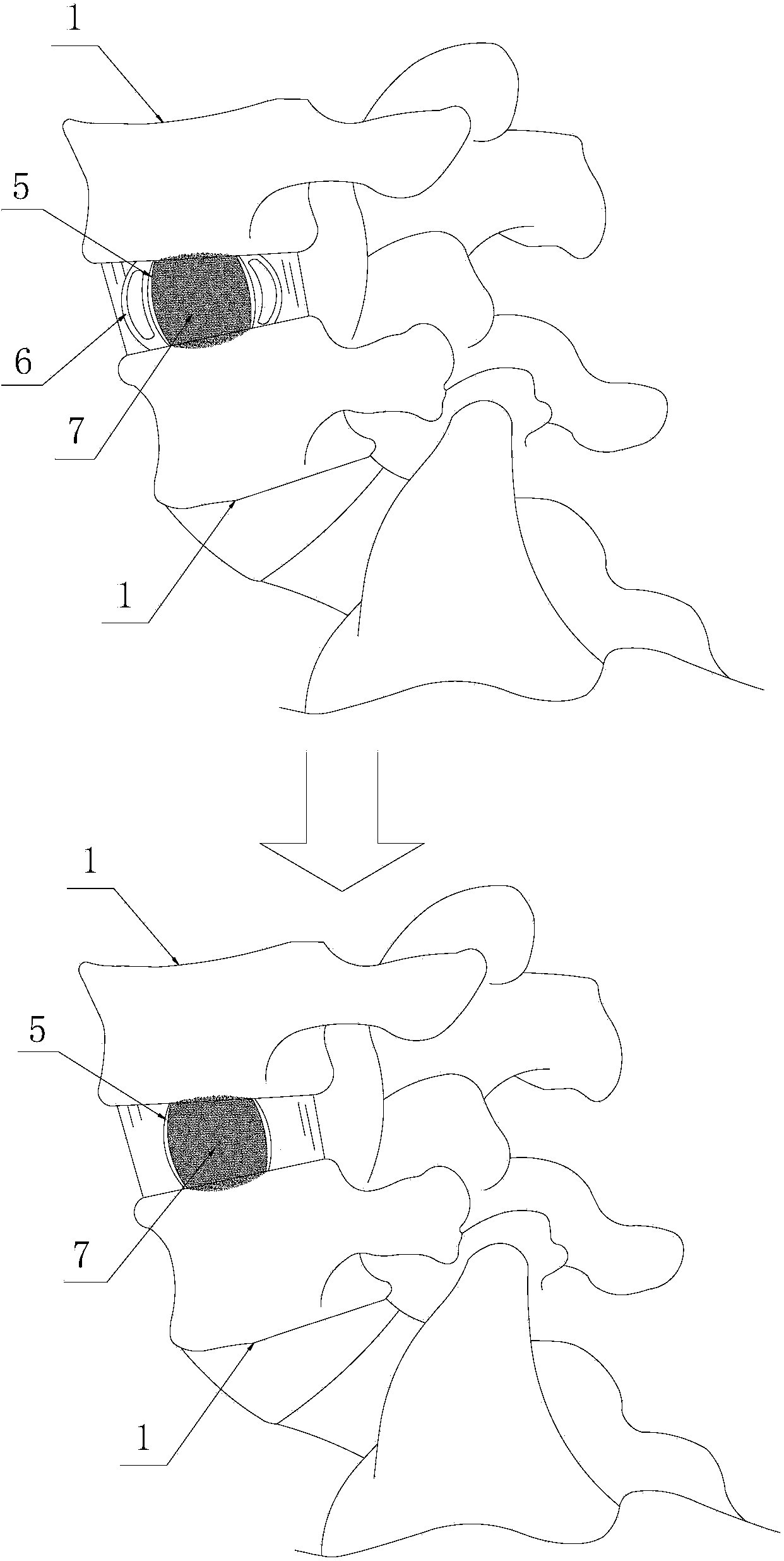

[0034] Example 2: Combining figure 2 As shown, the intervertebral filling and fusion device provided in this embodiment is used to fill between any two adjacent vertebral body endplates 1 of the human lumbar spine, and it has a support for the upper and lower vertebral body endplates. The supporting body of the plate 1, the supporting body has an annular lining 5 and a set of detachable annular airbags 6 placed on the periphery of the annular lining 5, and the ring inner side of the annular lining 5 Fill in the self-setting artificial bone material 7 (tricalcium phosphate bone cement) in a fluid state. When the self-setting artificial bone material 7 is solidified, its top and bottom are respectively connected to the upper and lower vertebral body endplates 1 fit the surface. Same as the conventional technology, the detachable annular airbag 6 is an open-loop airbag, which is convenient for detachment. The annular inner liner 5 is made of biocompatible silica gel, and has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com