High-pressure forming method in pipe

A technology of internal high pressure forming and pipe material, which is applied in the field of plastic forming of tubular parts, can solve the problems that the pressure will increase significantly, the production cannot be carried out, and the production cost will be increased, so as to reduce the production cost, avoid excessive internal pressure and uniform wall thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

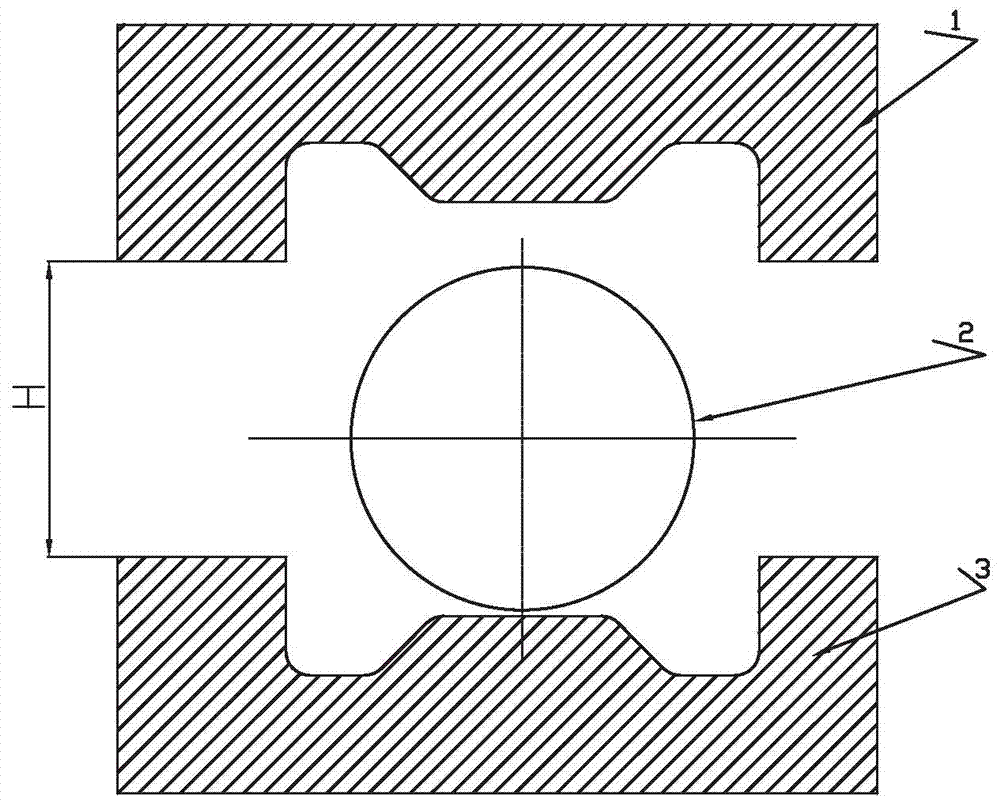

Embodiment 1

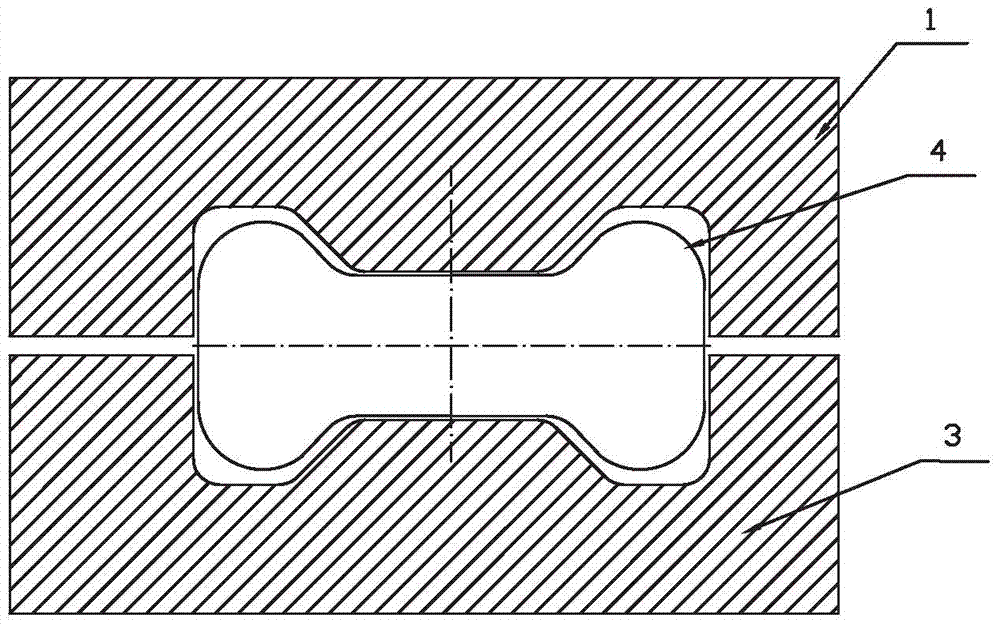

[0034] Embodiment 1: The pipe material 2 is made of 304 stainless steel, with a diameter of 60mm and a thickness of 2mm, and the section perimeter of the formed part is 1.3 times of the pipe material 2 perimeter, such as figure 1 shown. Using the traditional internal high pressure forming method, the forming pressure is 250MPa, the minimum radius of the formed part is 6mm, and the minimum wall thickness is 1.29mm. The test piece is formed by the high-pressure forming method in the pipe material 2 of the present invention, and the forming process is as follows:

[0035] When the distance H between the upper mold 1 and the lower mold 3 is 15mm, apply an initial internal pressure of 50Mpa (such as figure 2 shown), until the mold is completely closed, at the same time, the internal pressure is linearly loaded to 200MPa, and after the mold is completely closed, the shaping pressure is linearly loaded to 250MPa. The minimum radius r of the final formed part is 6mm, and the minim...

Embodiment 2

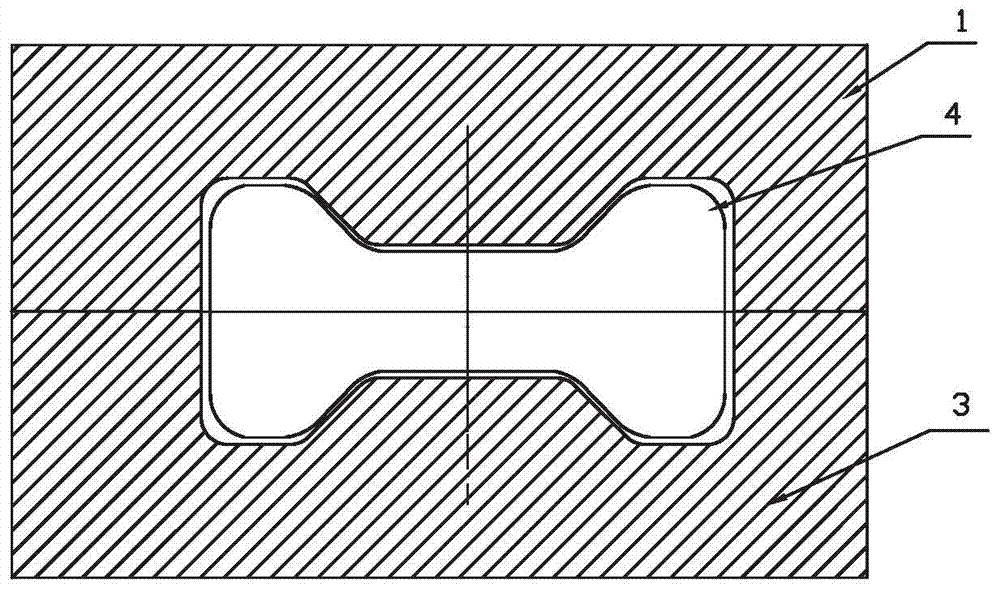

[0036] Embodiment 2: The pipe material 2 is made of 304 stainless steel, with a diameter of 60mm and a thickness of 2mm, and the section circumference of the formed part is 1.1 times of the circumference of the pipe material 2, such as Figure 4 shown. Using the traditional internal high pressure forming method, the forming pressure is 200MPa, the minimum radius r of the formed part is 7mm, and the corresponding minimum wall thickness is 1.82mm. Adopt the low-pressure internal high-pressure forming method of the present invention to form the test piece, and the forming process is as follows:

[0037] When the distance H between the upper mold 1 and the lower mold 3 is 10mm (such as Figure 5 As shown), apply an initial internal pressure of 50MPa until the mold is completely closed. At the same time, the internal pressure is linearly loaded to 100MPa. After the mold is completely closed, the shaping pressure is maintained at 100MPa. The minimum radius r of the final formed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com