High-speed electric spindle of ball

A high-speed motorized spindle and ball technology, applied in clamping, support, positioning devices, etc., can solve problems such as affecting the normal operation of the motorized spindle, high speed, and temperature rise of the motorized spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

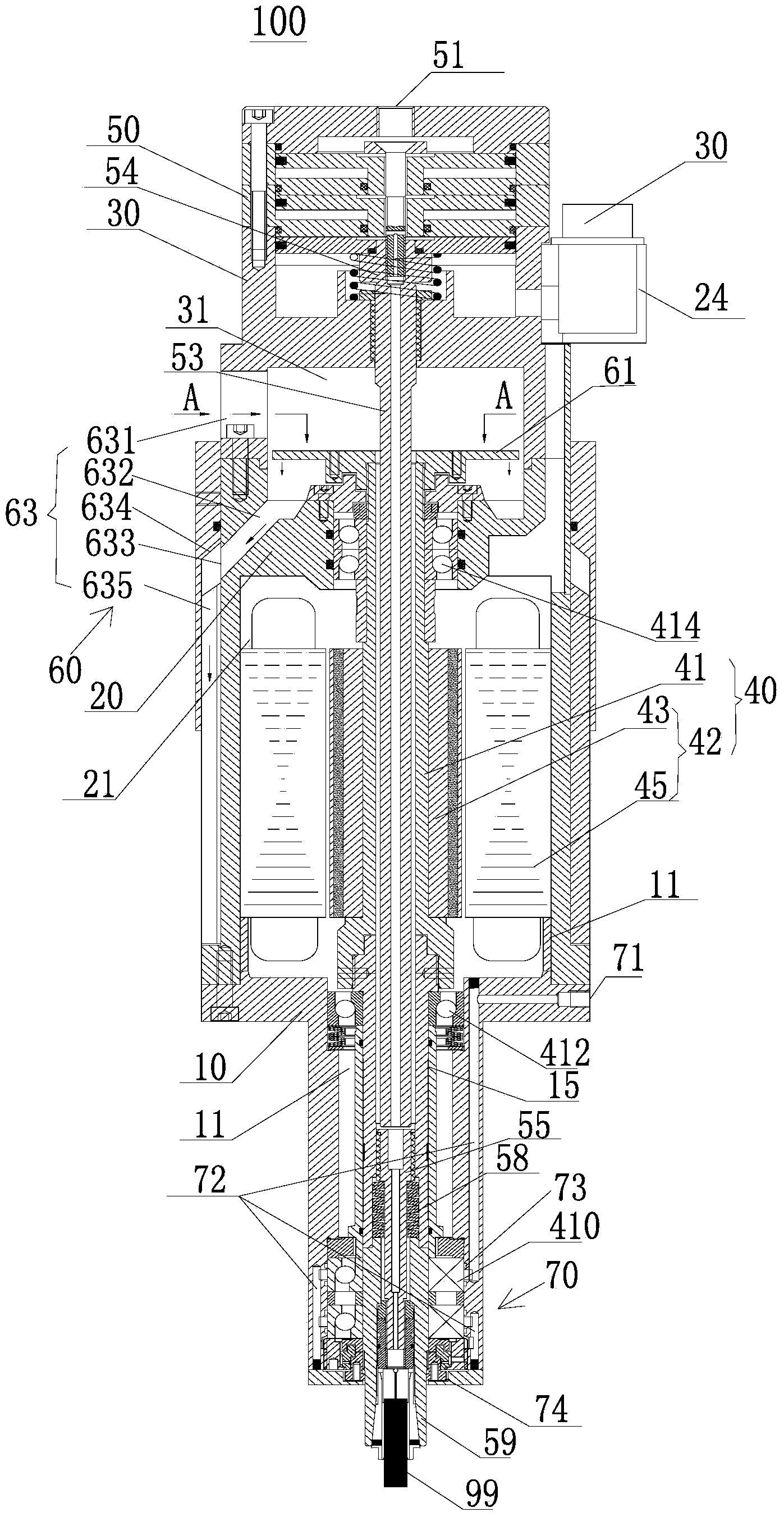

[0025] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0026] See figure 1 , the present invention relates to a ball high-speed electric spindle 100, which includes a body 10, a bearing housing 20, an aluminum water jacket 30, a shaft core assembly 40, a tool changing system 50 for changing a tool 99, an air cooling system 60 and an air sealing system 70. The body 10 is generally T-shaped, and the middle part thereof is inwardly recessed to form a first receiving cavity 11 . The bearing seat 20 is disposed between the machine body 10 and the aluminum water jacket 30 , and is co-enclosed with one end of the machine body 10 to form a second receiving cavity 21 . The aluminum water jacket 30 is disposed on the bearing seat 20 , and together with the end of the bearing seat 20 away from the machine body 10 , surrounds and forms a third receiving cavity 31 . Wherein, the first storage cavity 11 , the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com