High-accuracy gear milling machine for gear and rack

A high-precision, gear milling machine technology, applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of weak rigidity, long main transmission chain, inability to process racks, etc., to improve rigidity and expand processing. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

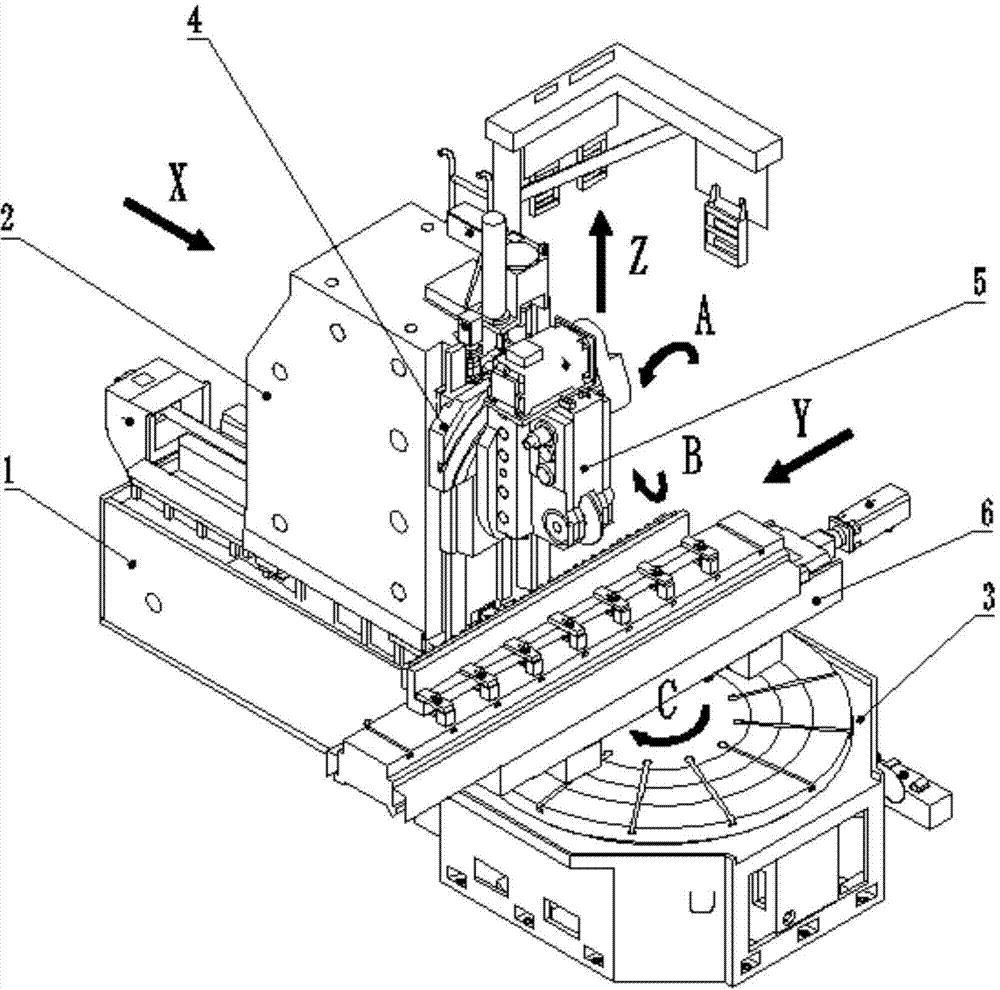

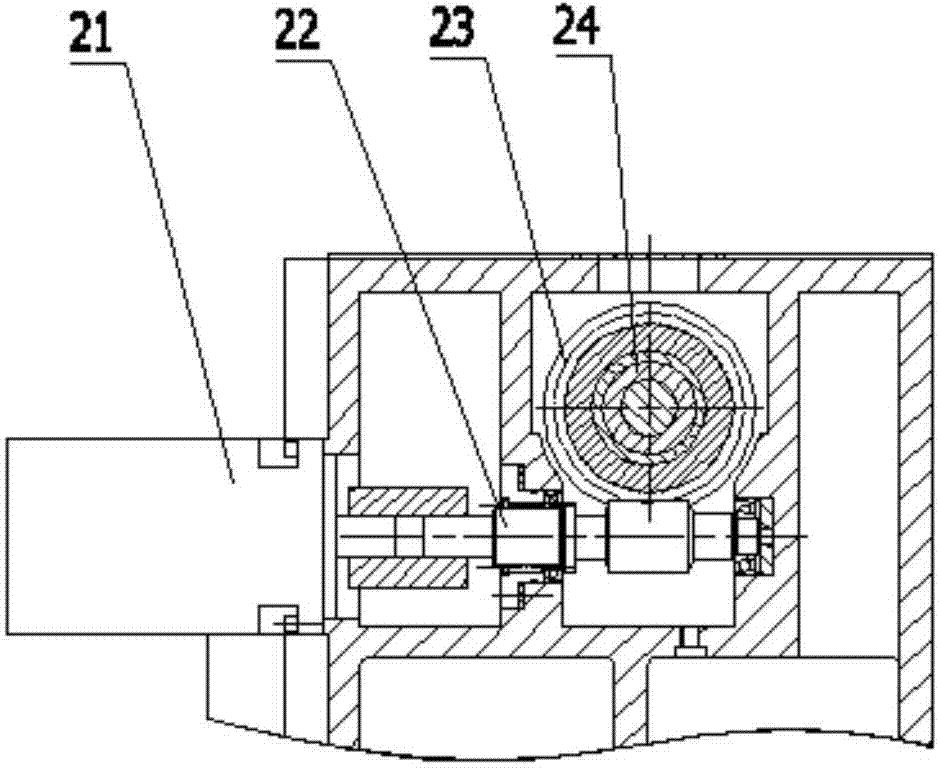

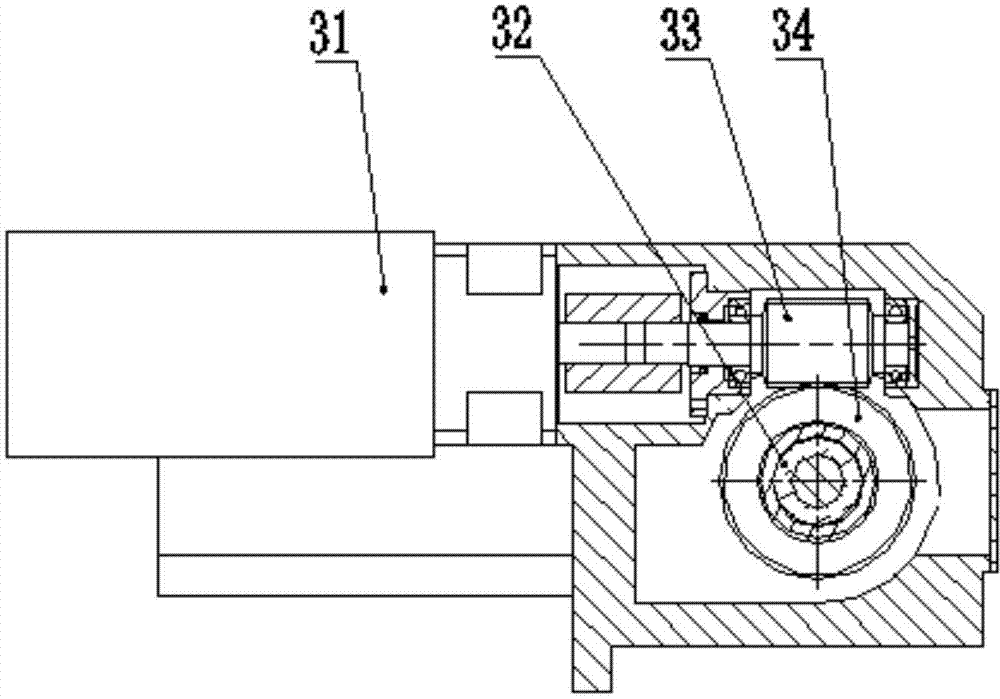

[0027] As shown in the figure, a high-precision gear and rack milling machine includes a bed 1, a large column 2, a workbench 3, a slide plate 4, a milling tool holder 5 and a rack feed unit 6; the large The column is installed on the bed, and the bed is provided with an X-axis driving mechanism that drives the radial feed of the large column; the slide plate is installed on the large column, and the large column is provided with a Z-axis that drives the axial feed of the slide plate Drive mechanism; the milling tool holder is installed on a slide plate, and the slide plate is provided with an A-axis driving mechanism that drives the rotation of the milling tool holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com