Online control device and online control method for electrolyte conductivity in electrolytic machining

A control device and conductivity technology, applied in electric machining equipment, machining special circuits, circuits, etc., can solve the problems of poor electrolytic machining accuracy, difficult to control machining accuracy, etc., to ensure service life and equipment safety, improve accuracy, and durability. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

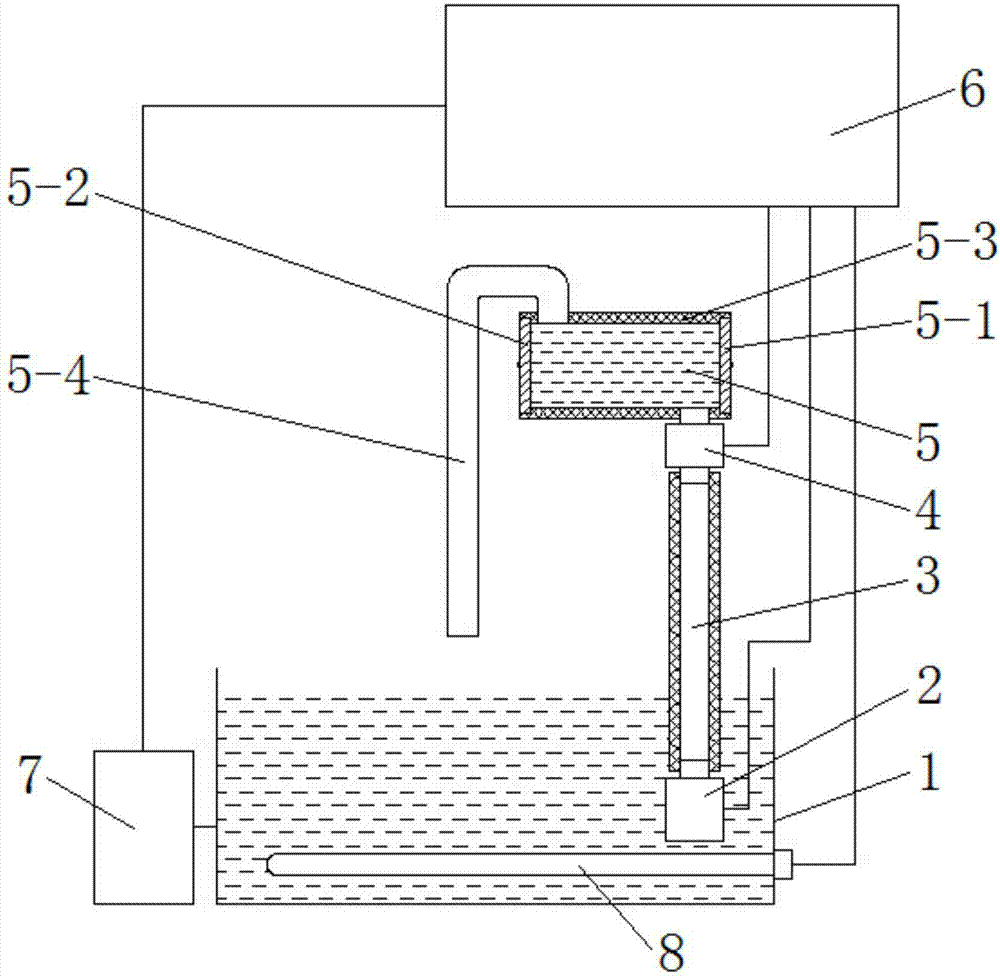

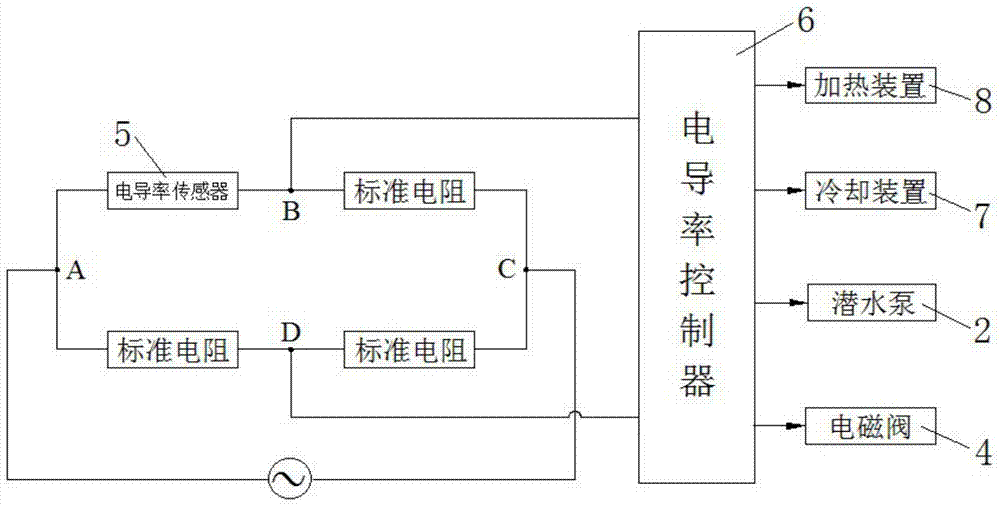

[0038] combine figure 1 and figure 2, an on-line control device for the conductivity of the electrolyte in electrolytic processing in this embodiment, including a submersible pump 2, an insulating tube 3, a solenoid valve 4, a conductivity sensor 5, a conductivity controller 6, a cooling device 7 and a heating device 8 . The submersible pump 2 communicates with the solenoid valve 4 through the insulating tube 3, the submersible pump 2 is located below the liquid level of the electrolyte in the electrolytic cell 1, and is used to transport the electrolyte in the electrolytic cell 1 to the conductivity sensor 5; the solenoid valve 4 Connected with the conductivity sensor 5, it is used to control the on-off of the insulating pipe 3 and limit the return flow of the electrolyte in the conductivity sensor 5; the conductivity controller 6 is connected with the submersible pump 2, the solenoid valve 4, and the conductivity sensor 5 respectively. , the cooling device 7 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com