Cutting torch gun with adjustable cutting torch angle and installing method thereof

A cutting nozzle and angle technology, applied in the field of cutting torches, can solve the problems of inconvenient replacement of cutting torches and decreased work efficiency, and achieve the effect of improving work efficiency and changing angles easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

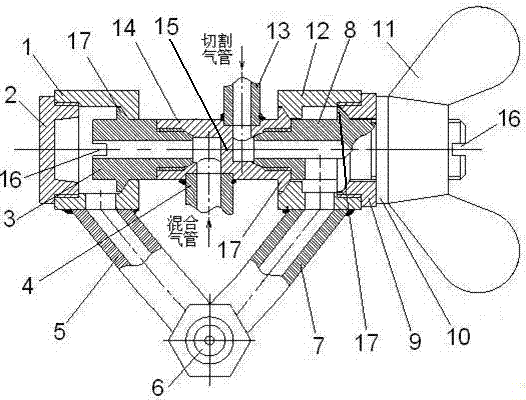

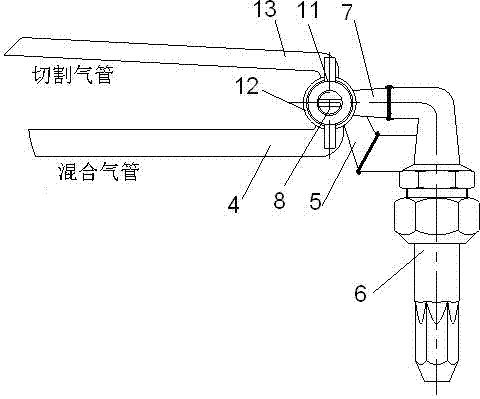

[0024] Example: A preferred embodiment of the present invention is that the mixing air pipe 4 and the cutting air pipe 13 are finally connected with the corresponding through holes on the back seat of the cutting nozzle 6, keeping the two passages unchanged. like figure 1 and figure 2 As shown, the inner cone cavity 1 and the outer cone cavity 12 are processed into a cavity piece with a length of 18 mm, a wall thickness of 3 mm, and an inner diameter of 17 mm using a copper rod with a diameter of 23 mm. The outer end of the cavity of the inner cone cavity 1 is set With blocking cover 2, figure 1The coaxial inner surfaces of the inner cone cavity 1 and the outer cone cavity 12 corresponding to the two pairs of cavities are designed with installation through holes with a diameter of 10.2mm, respectively on the inner sides of the two cavity installation through holes Or the outer edge is processed into a conical surface with a height of 3.4mm, which constitutes the inner con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com