Tail end operational tool assembly of mechanical arm

A technology of end operation and tool assembly, which is applied in the direction of manipulators, manufacturing tools, portable mobile devices, etc., can solve the problems of large volume and mass, complex mechanism of end operation tool adapter, etc., and achieve small volume and mass, small influence, light and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

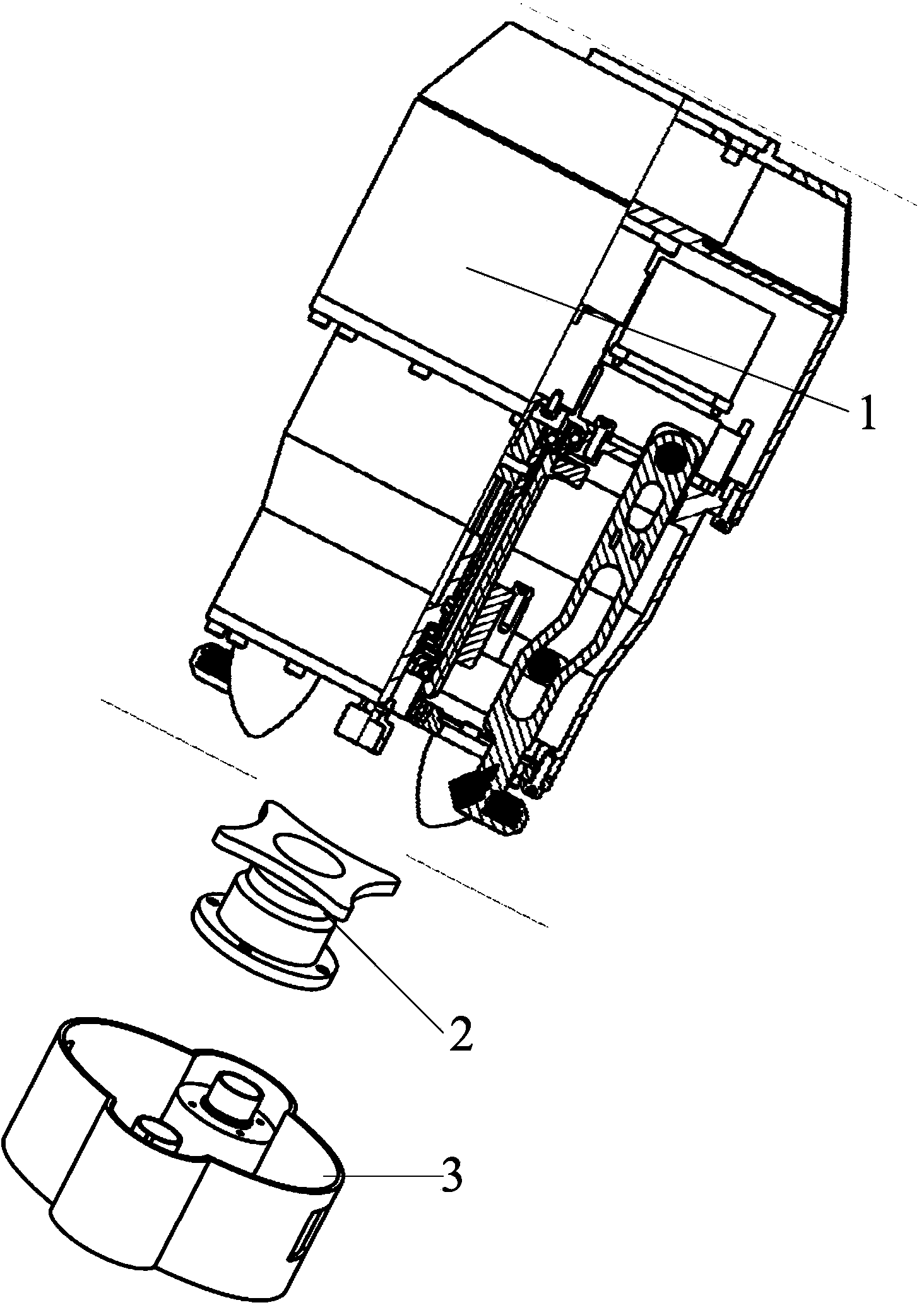

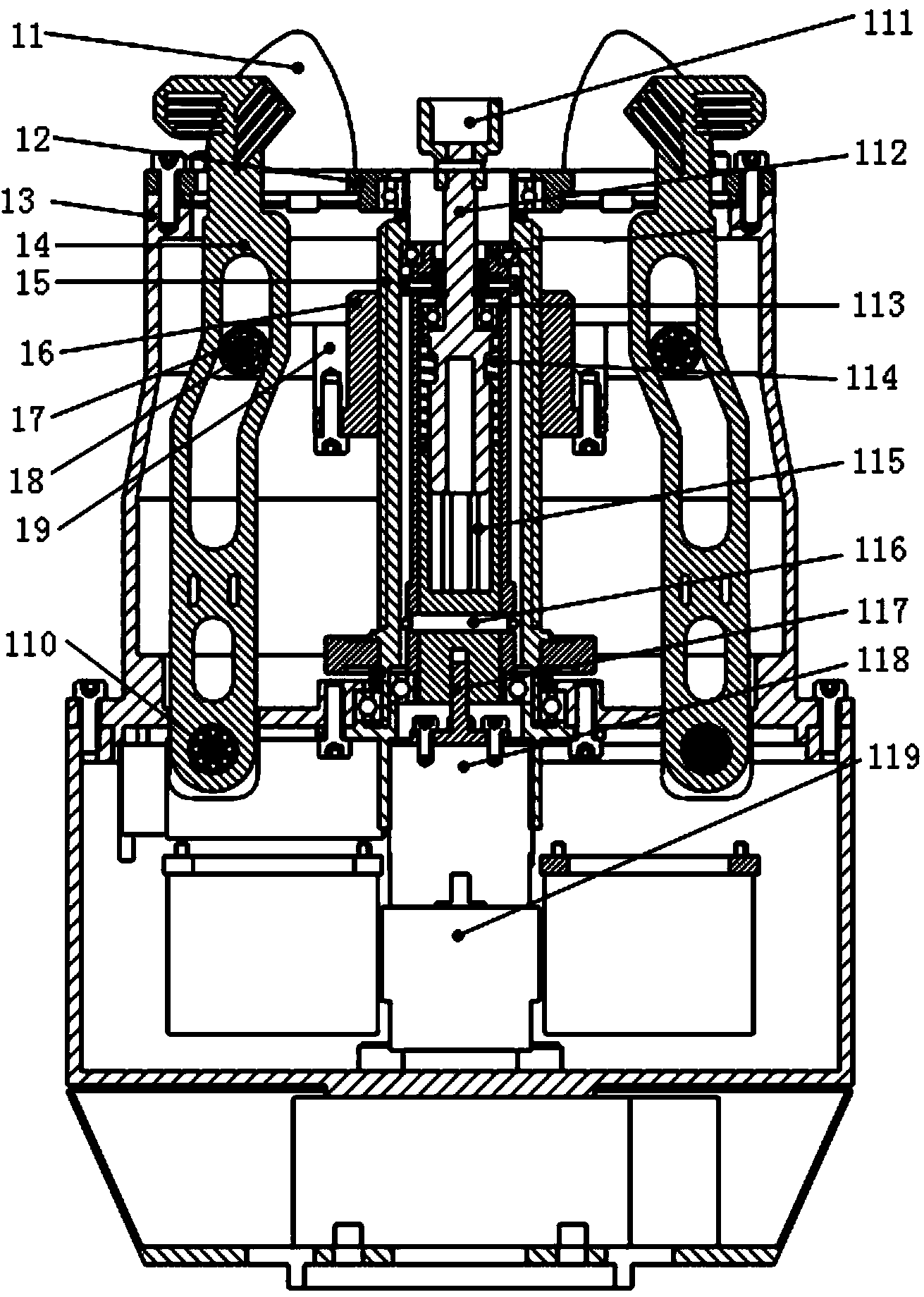

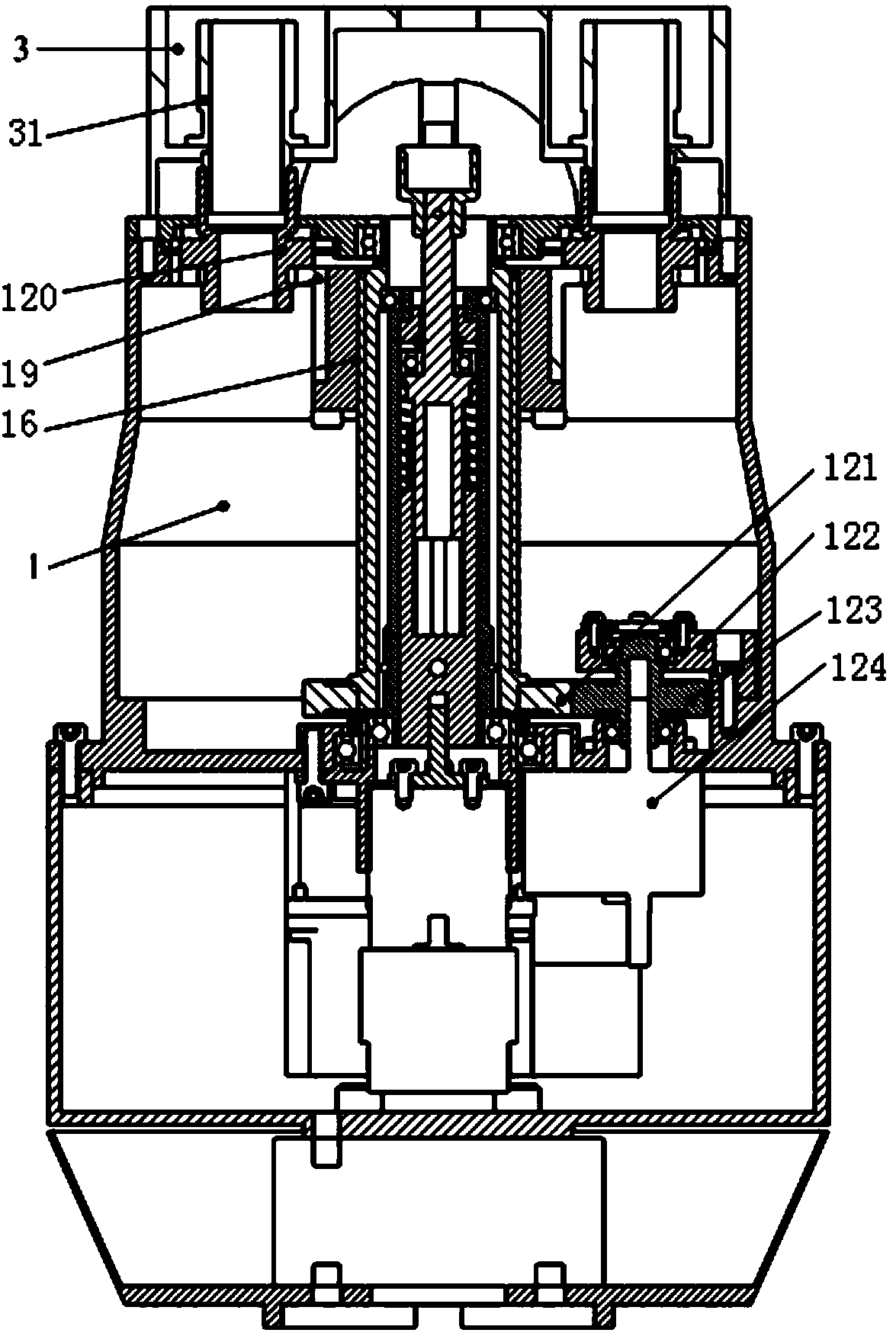

[0033] see Figure 1-3 , the manipulator end operation tool assembly of the present invention includes an end operation tool 1 and an adapter, and the end operation tool 1 includes a housing 13, an end cover 12, several guide blocks 11, fingers 14, a ball screw 15 and a driving mechanism. The end cover 12 is connected to the housing 13 by screws to form a supporting structure of the end operation tool 1 . The four guide blocks 11 are mounted on the end cover 12 by means of screw connection, and the ball screw 15 is arranged in the housing 13 and supported by two deep groove ball bearings. Ball screw 15 is connected with grasping finger 14 by lead screw nut assembly, and ball screw 15 can drive grasping finger 14 motions, and drive mechanism can drive ball screw 15 to rotate, and adapter can cooperate with guide block 11 and grasping finger 14. Among them, the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com