Cutter wheel holder unit

A technology for cutter wheel holders and scoring wheels, which is applied to electrical components, manufacturing tools, glass manufacturing equipment, etc., and can solve the problems of reduced rotational resistance and difficulty in stability of scoring wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and features of the cutter wheel holder unit proposed according to the present invention will be described below. Efficacy, detailed as follows.

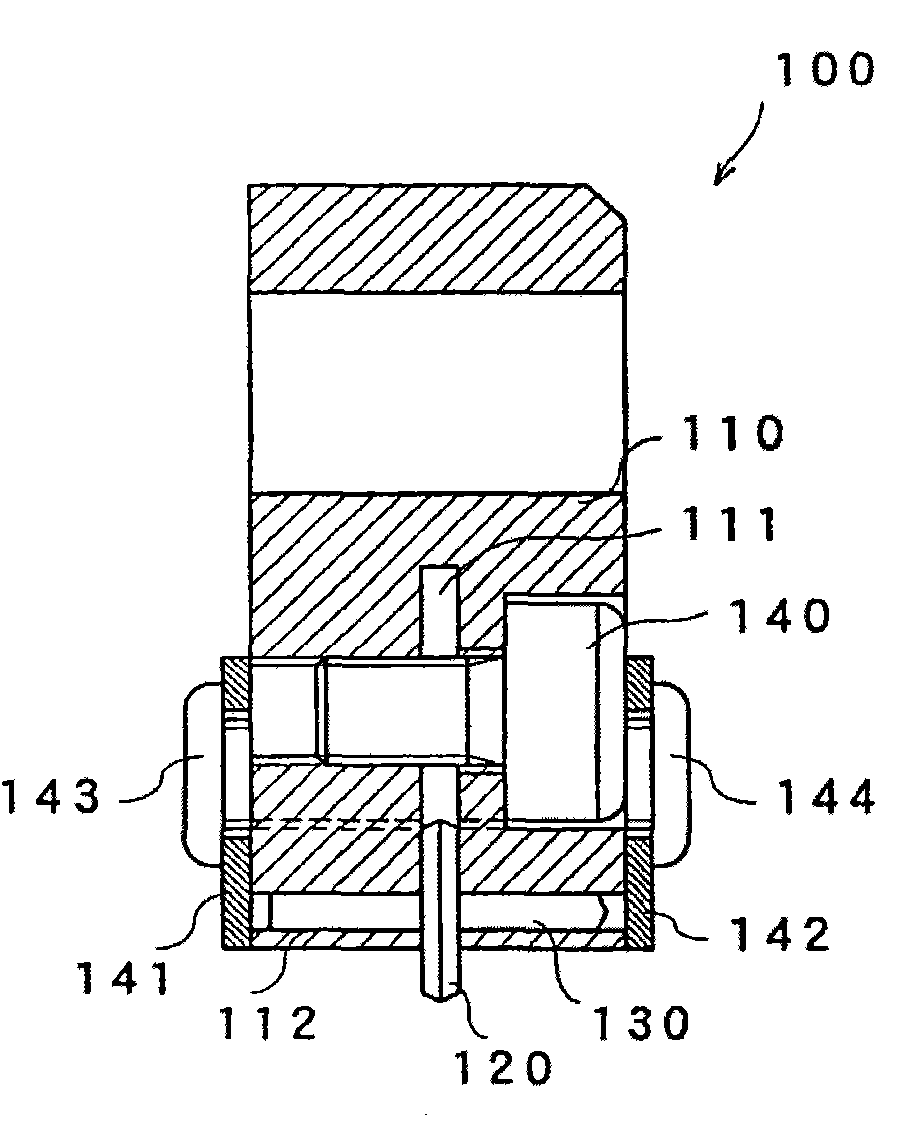

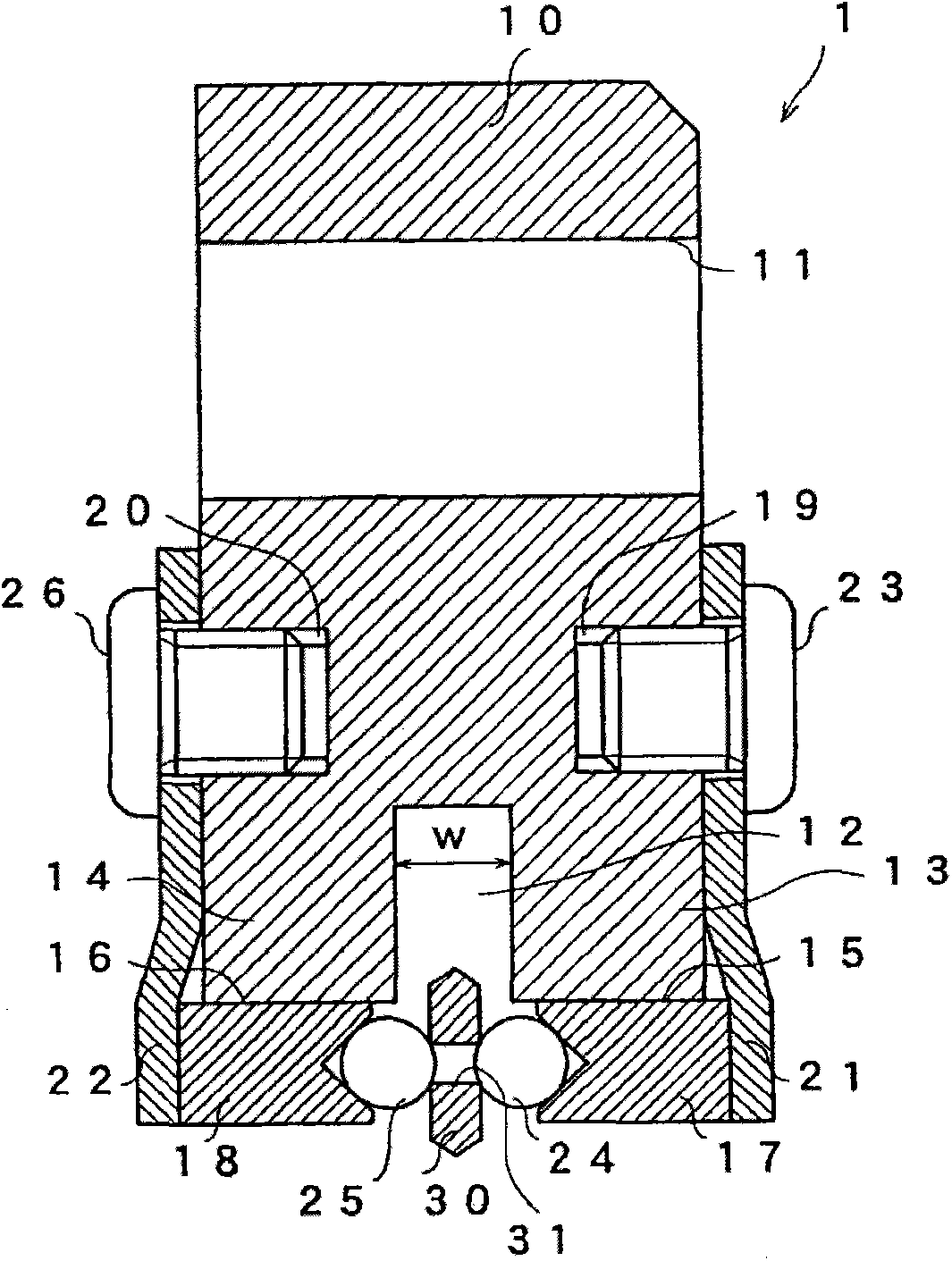

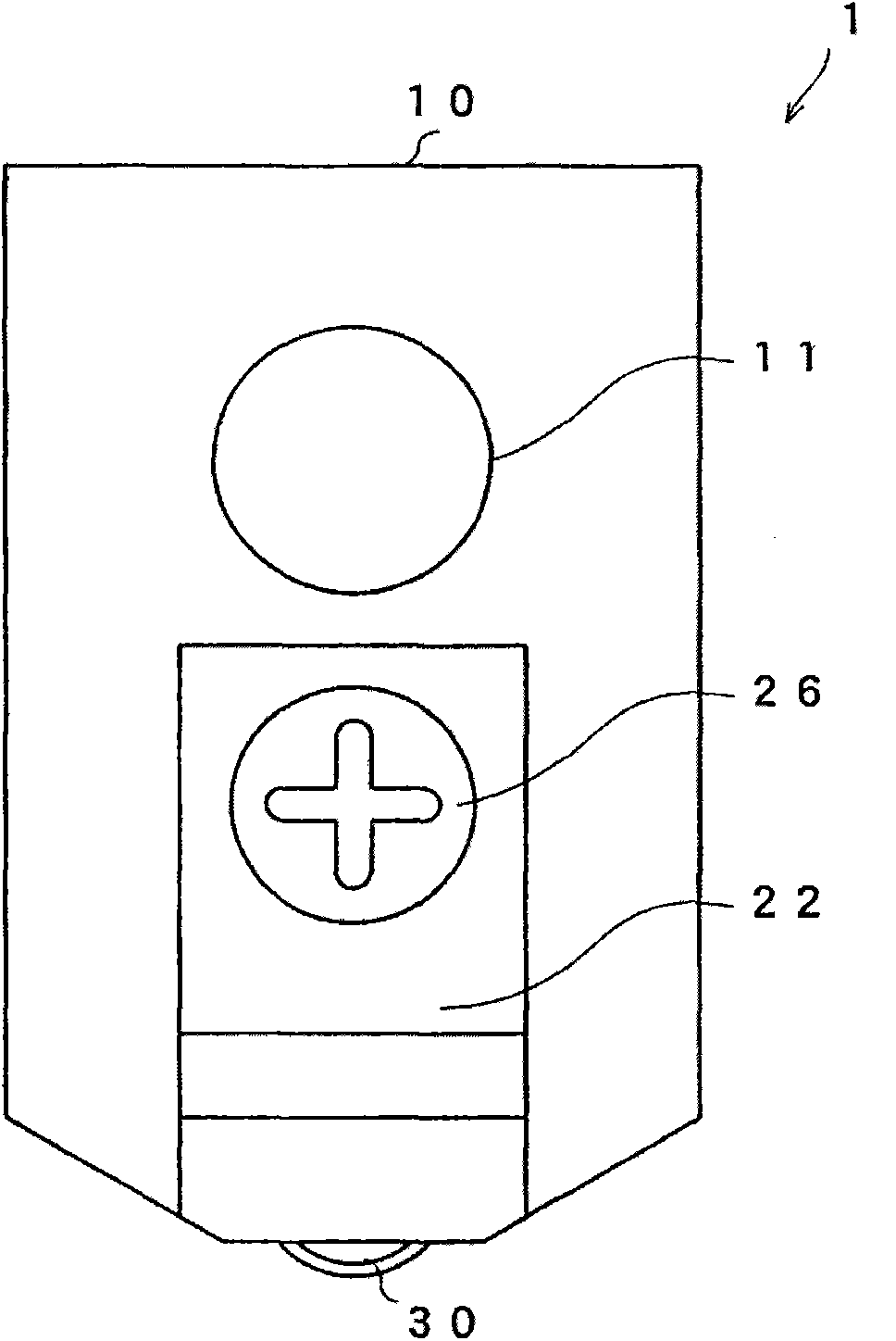

[0041] The cutter wheel holder unit according to the first embodiment of the present invention will be described using the drawings. figure 2 is a sectional view of the wheel holder unit, image 3 is its front view. The wheel holder unit 1 has a wheel holder 10 and a scoring wheel 30 , and holds the scoring wheel 30 rotatably at the lower end of the wheel holder 10 . Cutter wheel holder 10, as in Figure 4 As shown in the front view, it is a cuboid-shaped member with the lower left and right parts cut, and has a through hole 11 for fixing the cutter whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com