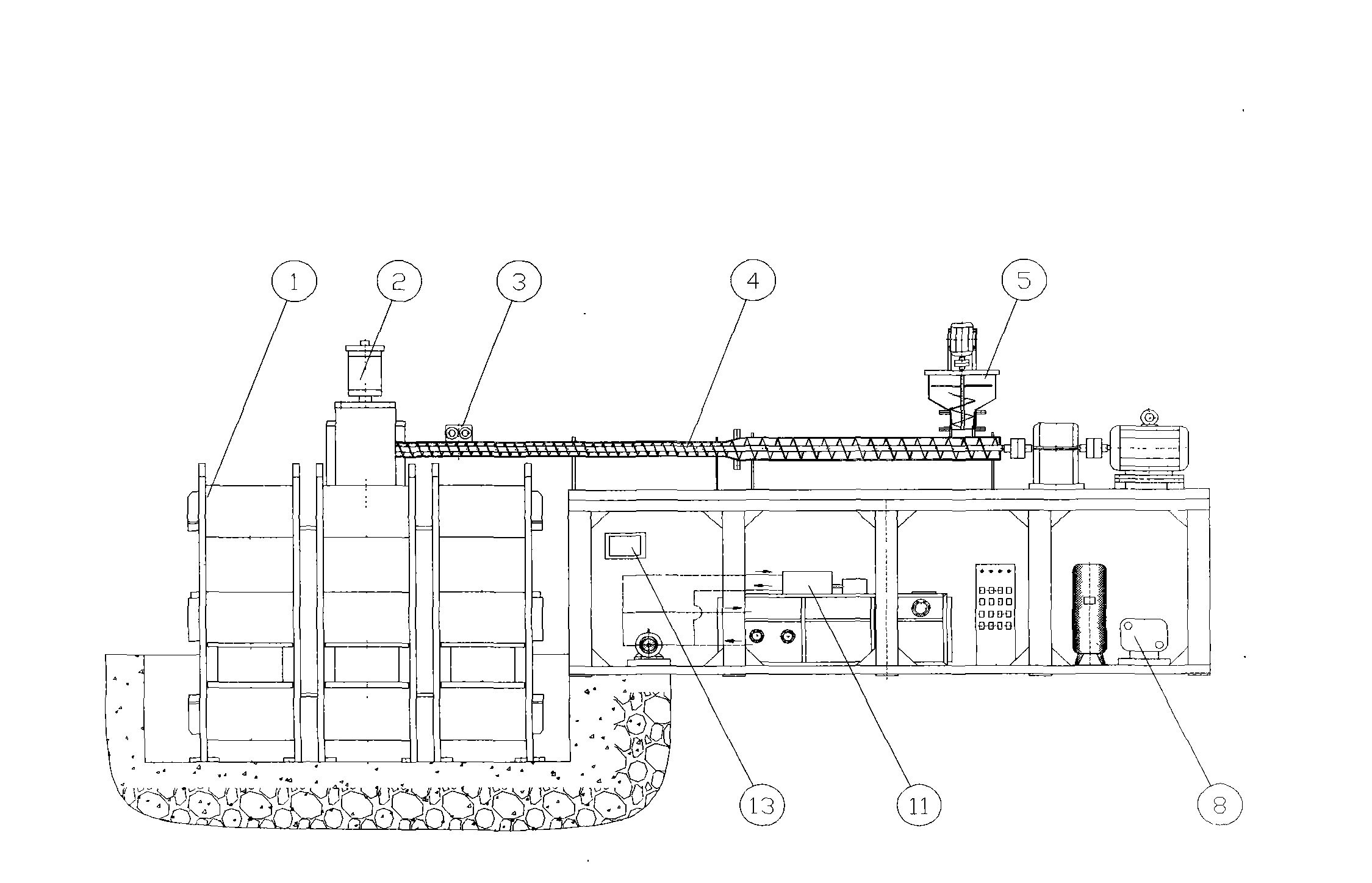

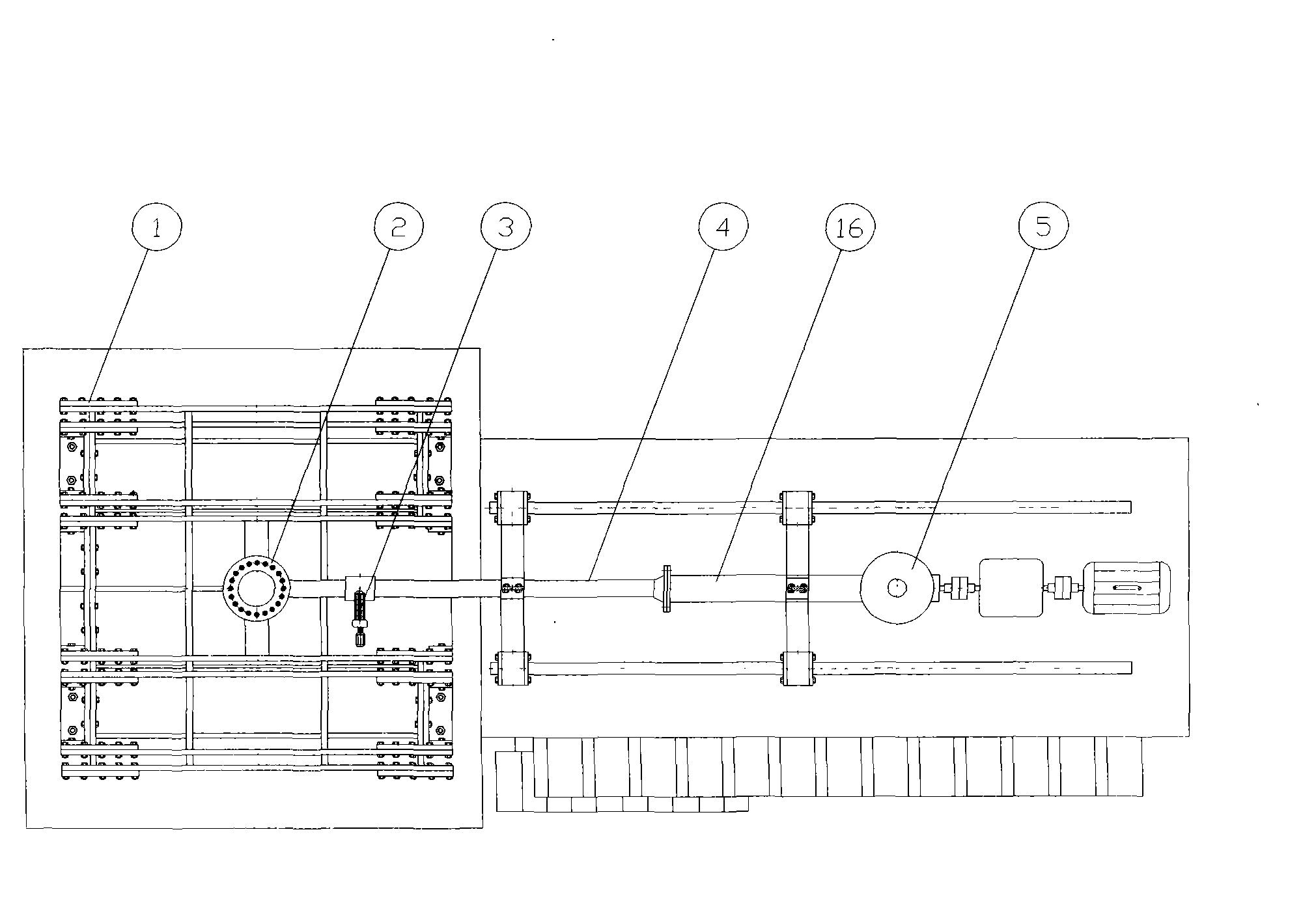

High-capacity injection moulding machine

A large-capacity, forming machine technology, applied in the direction of coating, etc., can solve the problems that cannot be used directly, and cannot be injection-molded into large-scale rubber and plastic products, so as to reduce processing costs, improve labor productivity, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] When in use, the dried plastic or rubber raw material enters from the hopper without interruption. Due to the shearing, friction and external heating of the screw rod, pre-plasticizing is realized, and the material is melted into a viscous flow and enters the silk mixing chamber. The mixed material enters the storage injection molding cylinder. The mold is pushed from the bottom to the top by the mold clamping cylinder to close the mold quickly, and the mold clamping cylinder is activated to lock the mold with the taper pin. Immediately open two pairs of injection molding cylinders to realize high-pressure injection molding, and quickly inject pre-molded materials into the mold cavity. After being pressurized twice by the press and kept under pressure for a specified period of time, the molded product is ejected by the ejector mechanism, and a working cycle is completed.

[0019] Through the automation and hydraulic system, the machine achieves the linkage of the whole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap