Device and method for manufacturing carrier bands

A technology of carrier tape and transmission device, which is applied in the production of carrier tape and the packaging of electronic components. It can solve the problems of poor bonding between the upper surface of the carrier tape and the adhesive tape, rough upper surface, etc., and achieve uniform thickness, easy falling off, The effect of precise angle and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the description of specific implementations of the present invention, the implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

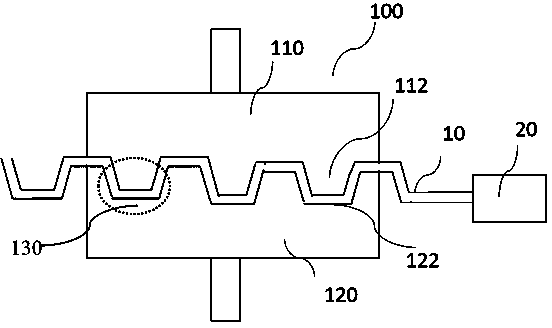

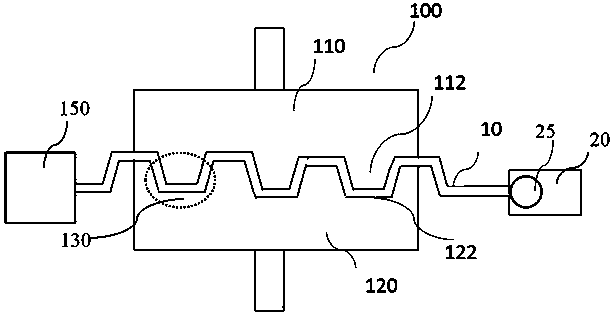

[0018] figure 1 Show the structural representation that the present invention makes carrier tape device, described device mainly comprises a carrier tape extruder 20 and a processing die 100, and described processing die comprises an upper die holder 110 and lower die holder 120, upper die holder 110 A plurality of protrusions 112 are evenly and equidistantly arranged, and the lower mold base 120 is evenly arranged on the lower mold base 120 to match the protrusions 112 in the upper mold base 110. The processing area 130 of the belt 10 . The extruder 20 stores and heats the material used for making the carrier tape, and heats and melts the material for making the carrier tape, so that the processing mold 100 can be extruded and shaped. Usually, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com