Hydraulic unit for vehicle brake system with motor bearing

A technology for hydraulic equipment and vehicle braking, applied to shafts and bearings, rigid brackets of bearing components, brakes, etc., can solve the problems of knocking noise, vibration of the drive motor, affecting NVH characteristics, etc., to avoid joint gaps, avoid Vibration, effect of improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

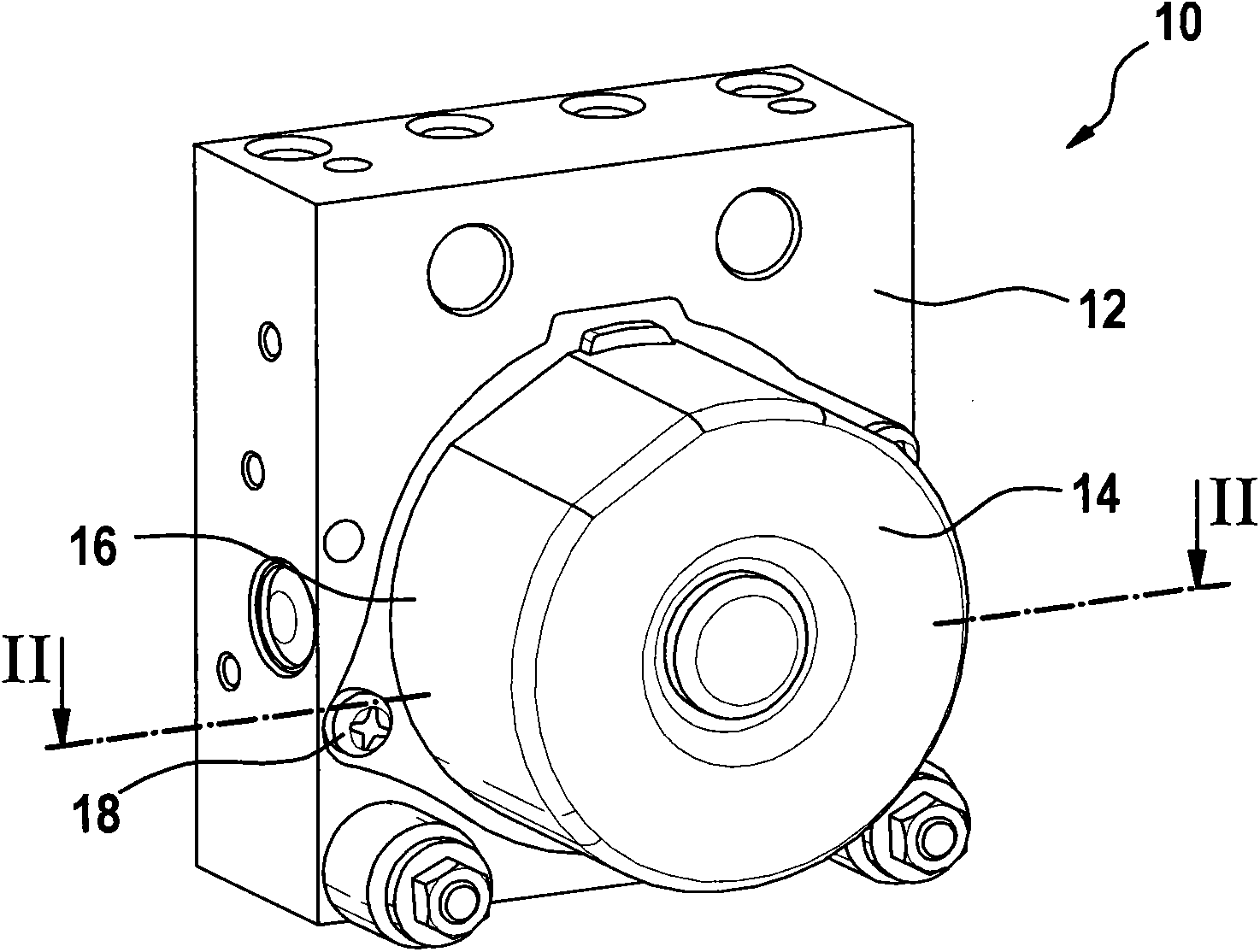

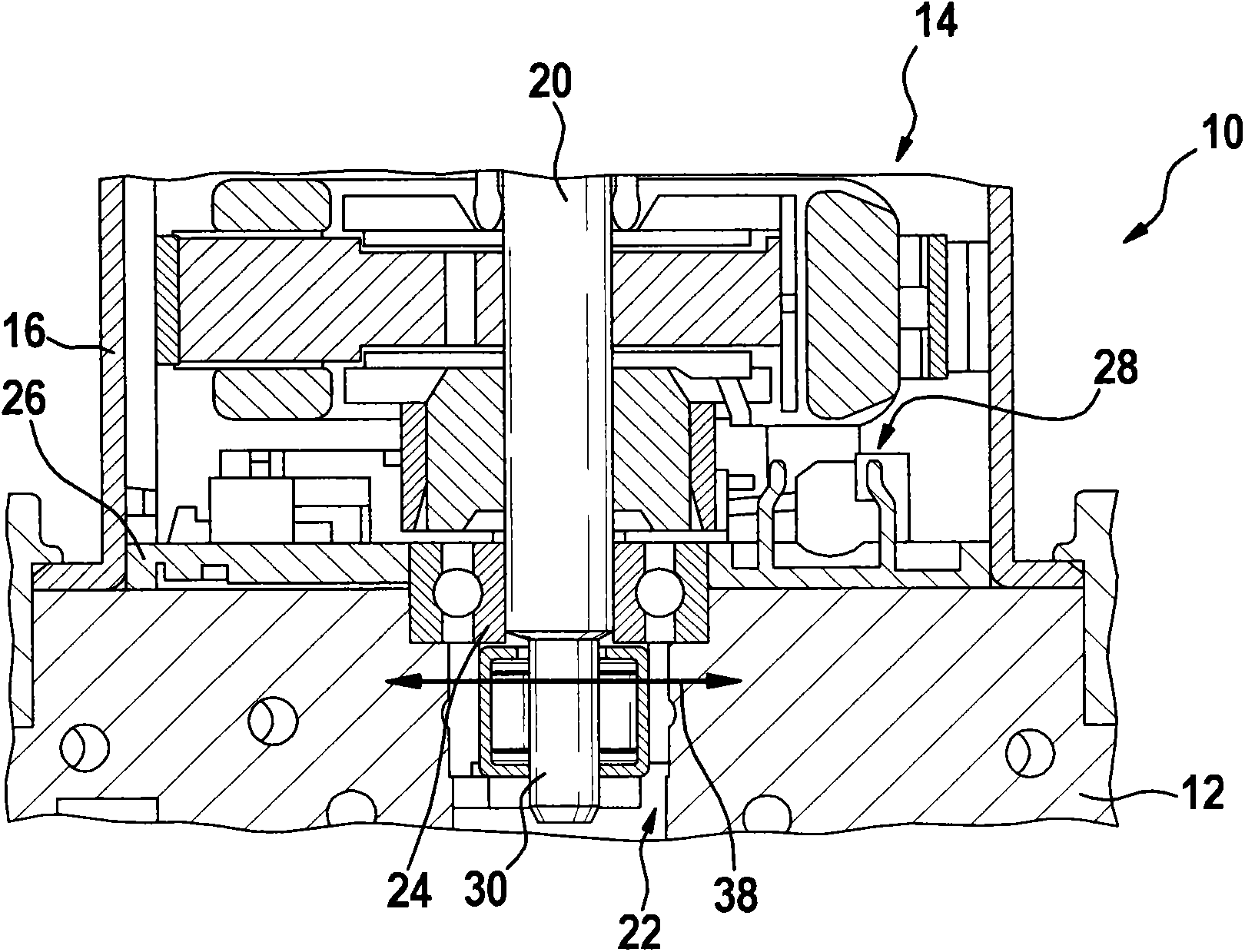

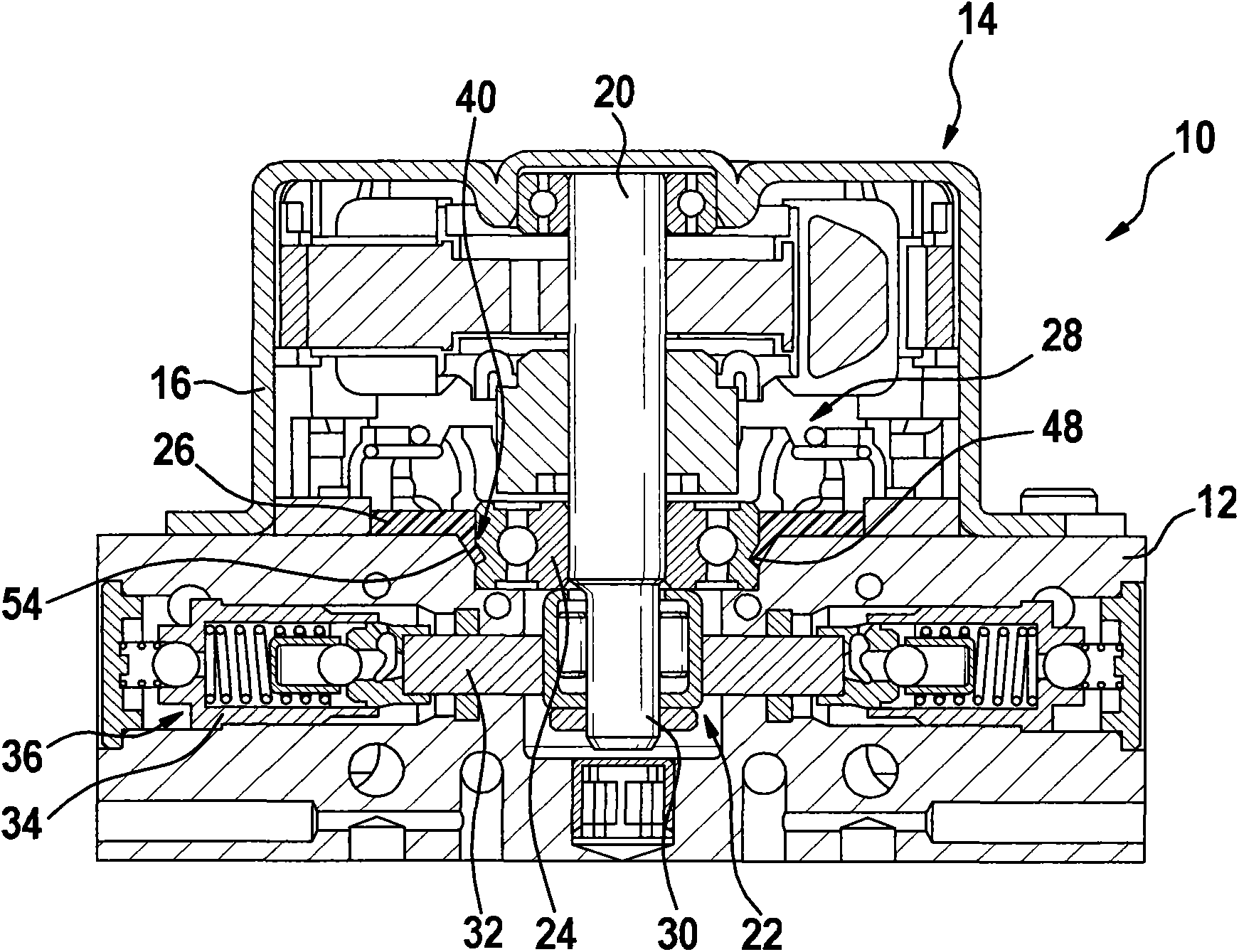

[0024] figure 1 and 2 A hydraulic system 10 of a vehicle brake system (not shown) is shown, which comprises a square hydraulic block 12 and a drive motor 14 which is fastened externally to this hydraulic block 12 . The drive motor 14 has a cup-shaped motor housing 16 , which is fastened in a conventional manner to the side of the hydraulic block 12 by means of at least two screws 18 and thus holds the drive motor 14 on the hydraulic block 12 .

[0025] The drive motor 14 drives a motor shaft 20 , which protrudes through a bore 22 into the hydraulic block 12 and is mounted in the hydraulic block 12 by means of a motor shaft bearing 24 . Furthermore, bearing caps 26 are provided as A bearing caps for delimiting the motor interior 28 , for accommodating the motor shaft bearing 24 and for pre-centering the drive motor 14 prior to assembly on the hydraulic block 12 .

[0026] Attached to the motor shaft 20 is an eccentric 30 which, during operation, rotates together with the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com