Automobile top locking type oil vapor recovery sealing device

A sealing device, oil and gas technology, applied in packaging, transportation and packaging, containers and other directions, can solve the problems of inability to provide pressing force, waste of resources, pollute the environment, etc., to overcome the settlement of tankers, the pressing force is stable and reliable, and the operation is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

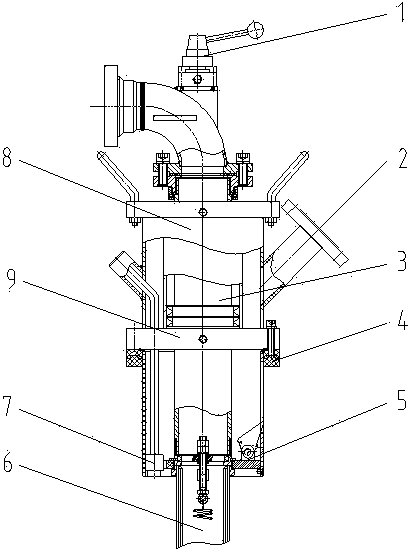

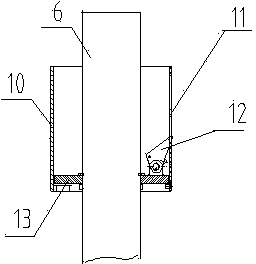

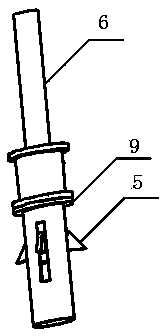

[0016] A locking type oil and gas recovery sealing device on the top of an automobile, including a vertical pipe 6 and a sealing cover 9 matched with the tank opening on the top of an oil tanker. Cylinder 8, the lower edge of the gas-liquid phase cylinder 8 is in contact with the upper surface of the sealing cover 9, the gas-liquid phase cylinder 8 is provided with an upper cover, and the upper cover is provided with a vertical pipe passage hole on the sealing cover 9. The through hole of the vertical pipe 6 passes through the through hole of the upper cover and the vertical pipe passing hole of the sealing cover, and the gas phase tube 2 is provided on the side wall of the gas-liquid phase cylinder body 8, and in the gas-liquid phase cylinder body 8 A vertical tube lifting cylinder 3 is provided, and the vertical tube lifting cylinder includes a cylinder body 16, an upper end cover 14 and a lower end cover 18 which are set outside the vertical tube. The upper cover of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com