Dry-type frication slice power output device applied to farm machinery and control method for same

A technology of power output and friction plate, applied in the field of dry friction plate power output device and its control, can solve the problems of high failure rate of the system, inability to guarantee pressing pressure, etc., and achieve high transmission efficiency, reliable pressing force, and transmission smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

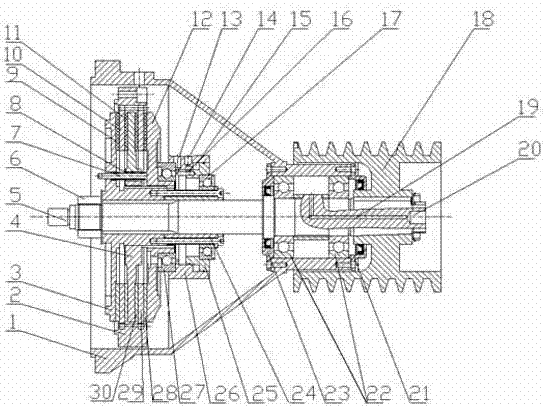

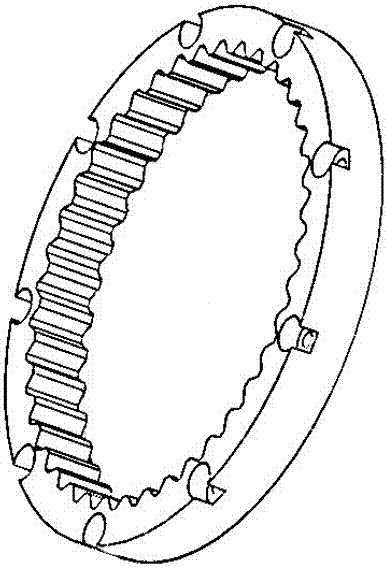

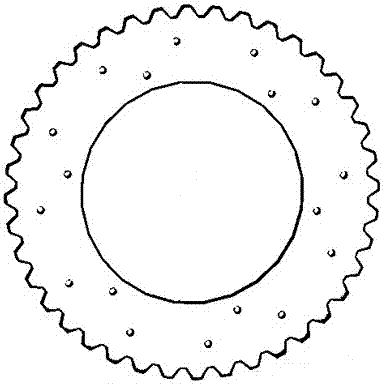

[0038] A dry-type friction plate power output device for agricultural machinery, including a housing 1 and an output shaft 5, one end of the housing 1 is sleeved on the output shaft 5 through a bearing, and the end of the output shaft away from the housing 1 is passed through a flat The key is connected with the pulley 18, and the housing is also provided with a ring gear 2, a friction plate I, a pressure-bearing device, and a pressing device. Located between the ring gear 2 and the output shaft 5, the pressing device is arranged on one side of the pressure-bearing device for outputting the pressing force; the pressure-bearing device includes a pressure-bearing plate 3 and a pressure plate 12, and the pressure-bearing plate 3 is connected to the pressure plate through a spline The output shaft 5 is connected, and a support plate is provided on the side away from the pressing device. The pressure plate 12 is connected to the pressure bearing plate 3 through a spline, and a pivot...

Embodiment 2

[0042] A dry-type friction plate power output device for agricultural machinery, including a housing 1 and an output shaft 5, one end of the housing 1 is sleeved on the output shaft 5 through a bearing, and the end of the output shaft away from the housing 1 is passed through a flat The key is connected with the pulley 18, and the ring gear 2, the friction plate I, the pressure-bearing device, and the pressing device are also arranged in the housing. Located between the ring gear 2 and the output shaft 5, the pressing device is arranged on one side of the pressure-bearing device for outputting the pressing force; the pressure-bearing device includes a pressure-bearing plate 3 and a pressure plate 12, and the pressure-bearing plate 3 is connected to the pressure plate through a spline The output shaft 5 is connected, and a support plate is provided on the side away from the pressing device. The pressure plate 12 is connected to the pressure bearing plate 3 through a spline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com