Chain cleaning machine

A chain cleaning and washing machine technology, applied to conveyors, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as low work efficiency, waste of energy, etc., achieve easy maintenance, convenient operation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

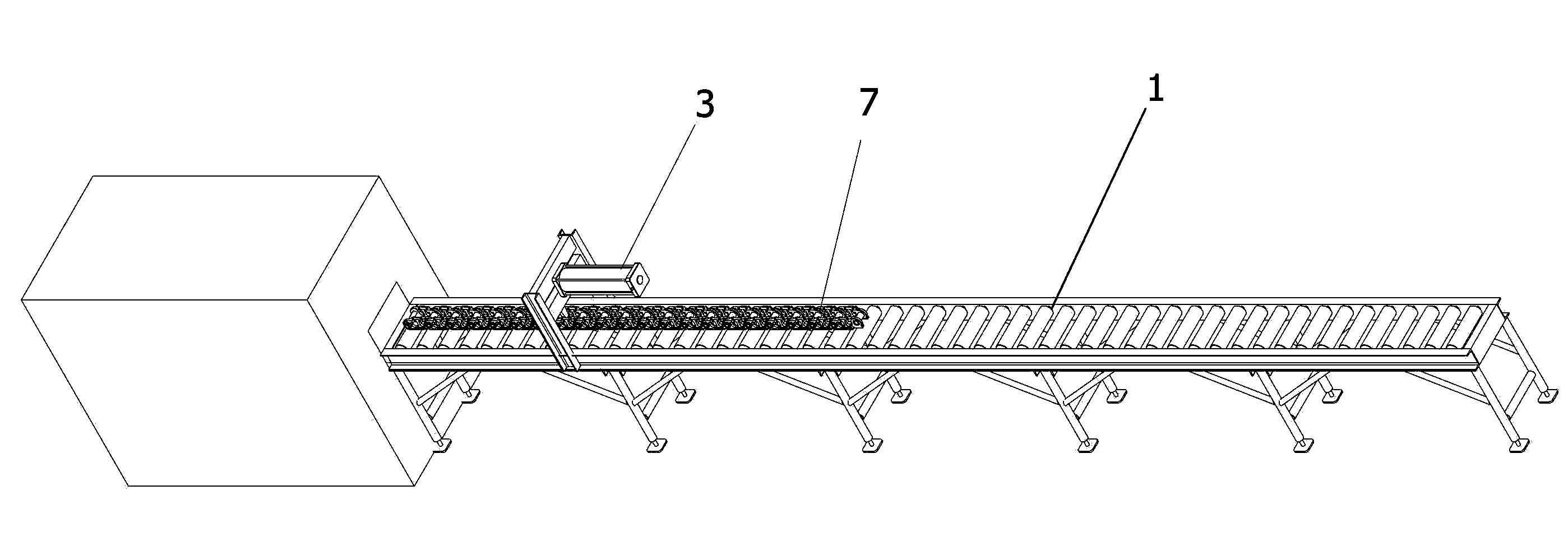

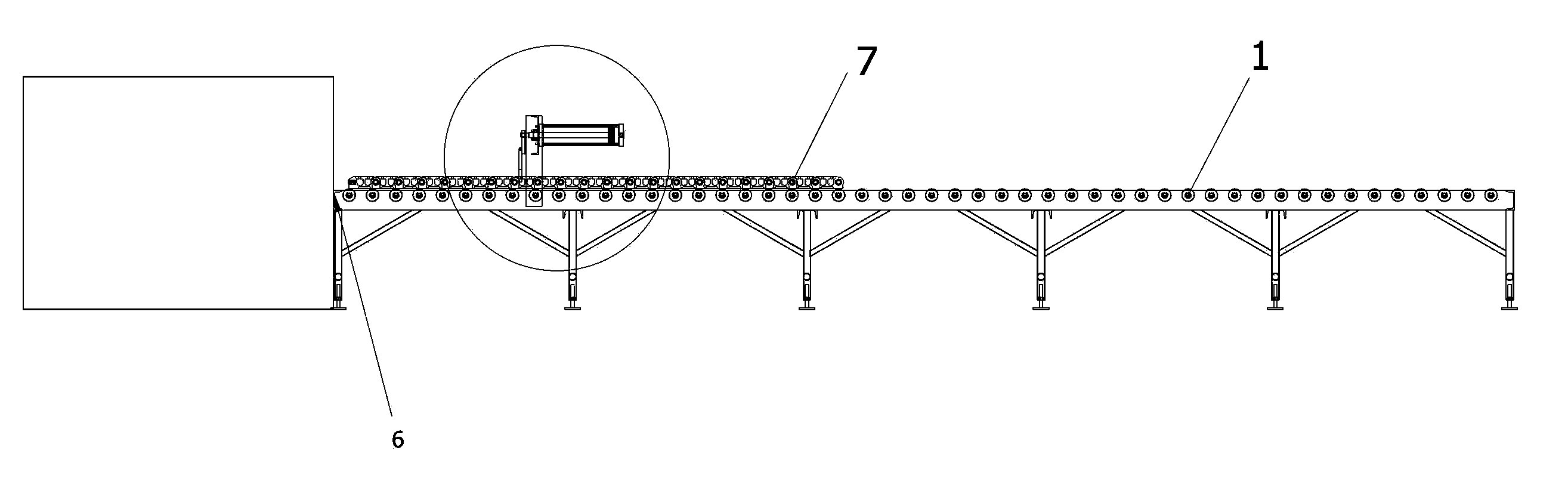

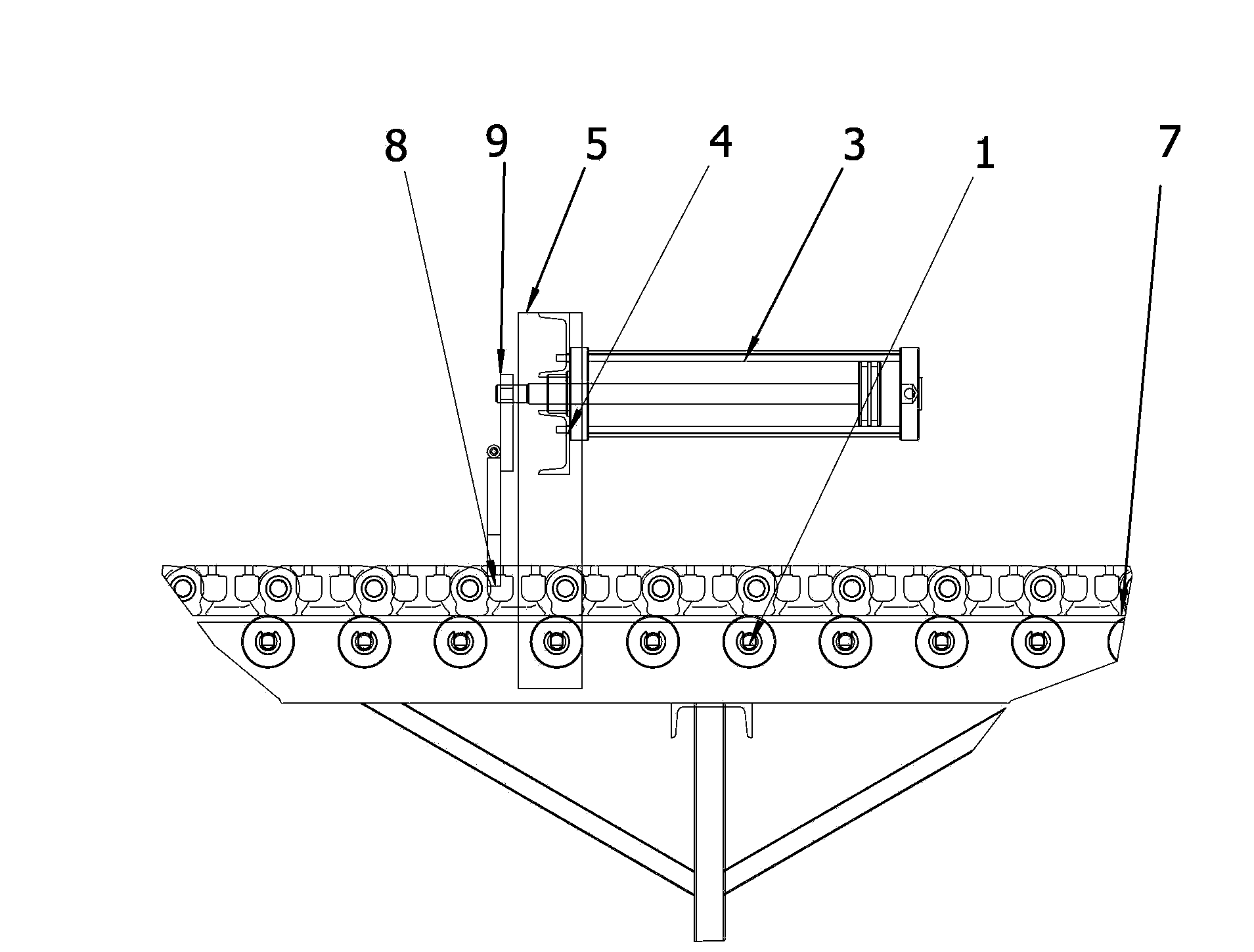

[0024] Such as Figure 5-9 As shown, the chain cleaning machine of the present invention includes a material guide frame 1 formed by side-by-side rollers, and a cleaning machine 6 provided at one end of the material guide frame 1 . The improvement of the present invention lies in that the material guide frame 1 is provided with a "door" frame body composed of vertical beams 5 and cross beams 4, the "door" frame bodies are two opposite sides, and the two "door" frame bodies The body is provided with a cooperating gear 21 and rack 22 through the supporting beam, and the two ends of the rack 22 are respectively hinged to the push plates 8 through a seat plate 9, and each push plate 8 faces away from the direction of the cleaning machine 6 respectively to rotate around the hinge axis. 10 one-way rotation mode settings. In addition, the rack 22 is also connected to an actuator that drives the rack to reciprocate.

[0025] In a preferred mode, the actuator is selected from the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com