How to make a shaftless screw conveyor

A technology of screw conveyor and manufacturing method, which is applied in the direction of packaging, etc., can solve the problems of difficult discharge of steel bars and concrete slag fragments, direct cutting of reinforced concrete without considering the shield, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

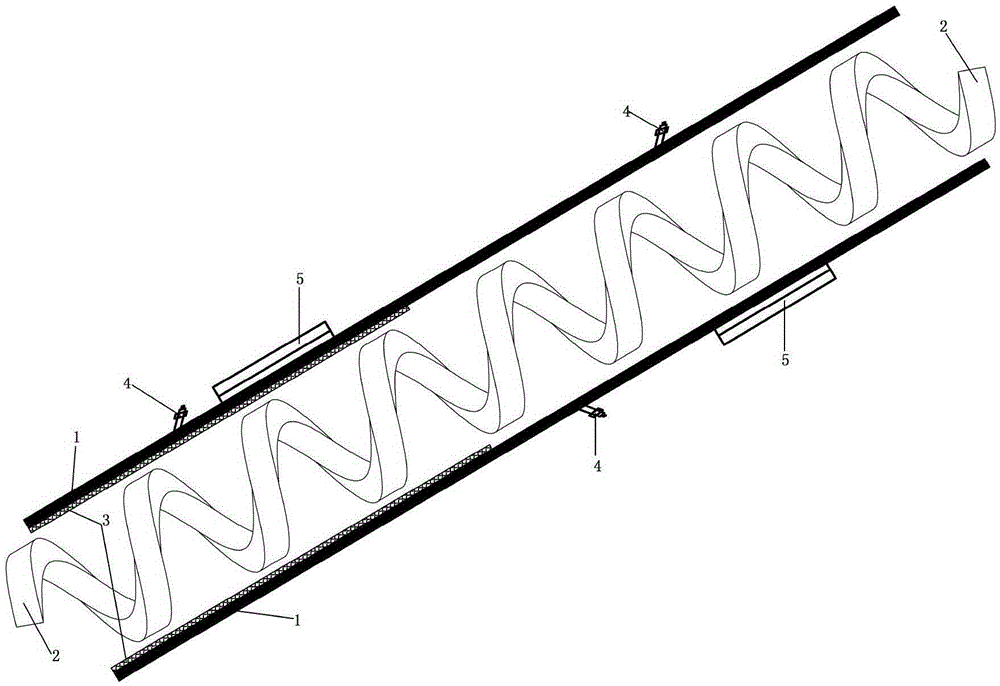

[0020] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0021] This embodiment is a shaftless screw conveyor manufactured in conjunction with the shield cutting of 14 large-diameter bridge pile foundation projects on Suzhou Rail Transit Line 2. The left and right lines of the project respectively cut 7 drills with a diameter of 1000 to 1200 mm in full section. Hole pouring pile, main reinforcement Φ20-22mm, concrete strength C30.

[0022] The method includes the following steps:

[0023] According to the allowable space inside the shield machine, the diameter of the inner wall of the screw conveyor cylinder 1 is taken to a maximum value of 670mm;

[0024] Assuming that the largest possible external dimension of the concrete fragment is 30cm, the pitch L of the screw blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com