Method for controlling electronic pattern machine to perform multiple sewing

A technology for controlling electronics and pattern machines, which is applied in the direction of program-controlled sewing machines, floral stitch sewing machines, sewing equipment, etc., and can solve the problems of multiple seam key points that cannot generate concave polygons, incompetence, and inability to cover all situations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Describe the present invention below in conjunction with specific embodiment:

[0036] In this embodiment, a method for controlling an electronic pattern machine to perform multiple seams adopts the following steps:

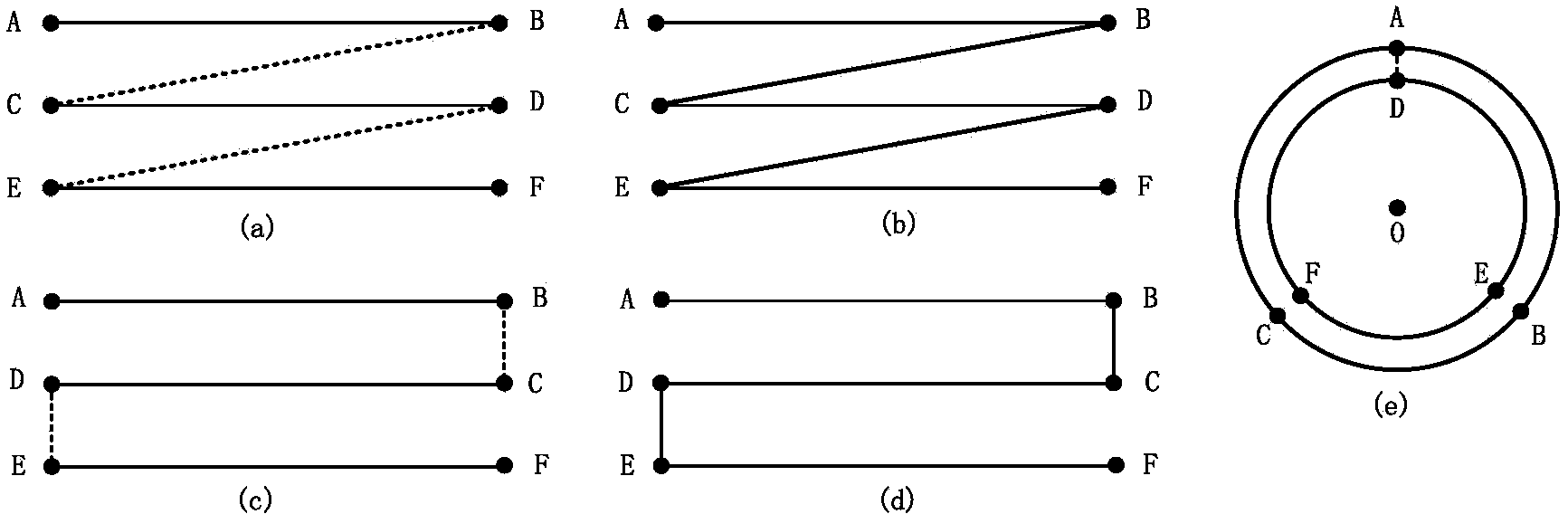

[0037] Step 1: Establish the key point data in the pattern data: divide the pattern into a number of sequentially connected basic geometric figures according to the sewing process. The basic geometric figures include straight line segments, circular arcs, circles and free curves. The data of several points of arcs, circles and free curves are key point data;

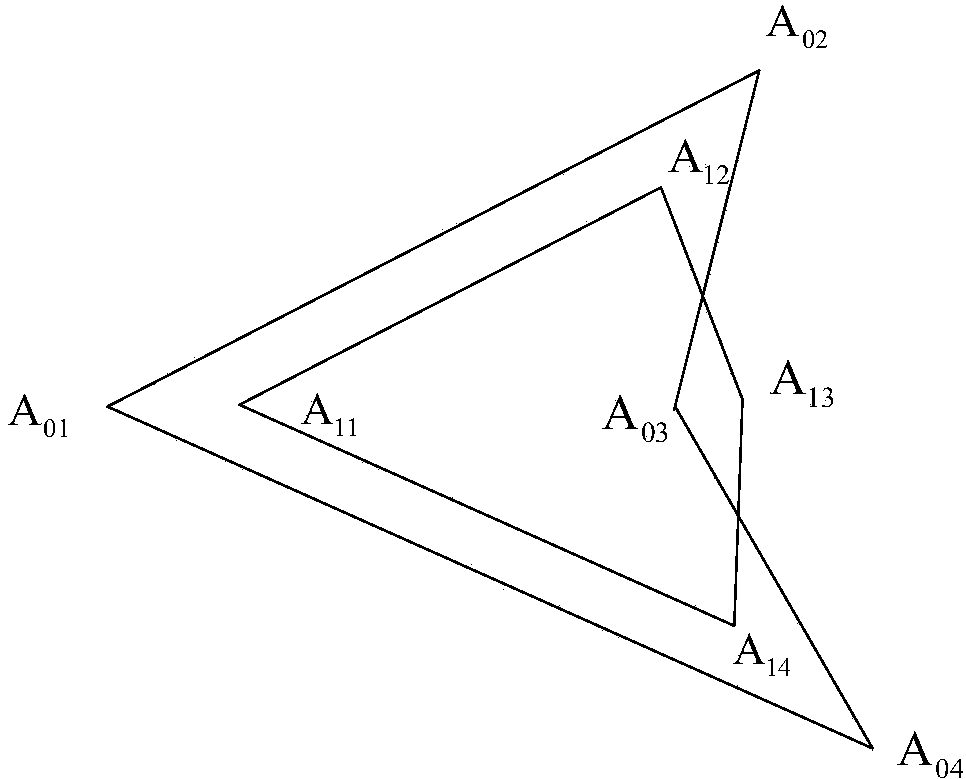

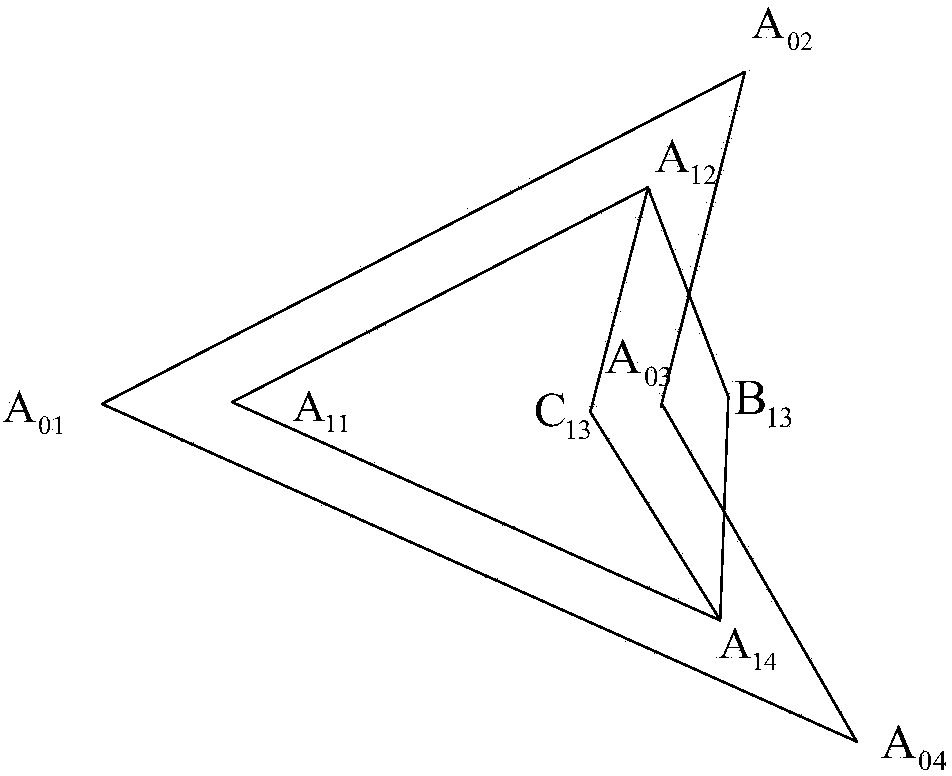

[0038] Step 2: Generate multiple seam key point data from the key point data in step 1:

[0039] Step 2.1: Connect the key points in step 1 into polygons in order;

[0040] Step 2.2: Find the unit vector of each segment of the polygon:

[0041] e ij → = A ij ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com