Macromolecular elastomer expansion joint

A polymer elastomer and expansion joint technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of difficult repair, easy damage, easy damage to expansion devices, etc., to achieve the effect of easy installation, satisfying bridge deformation, and smooth driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

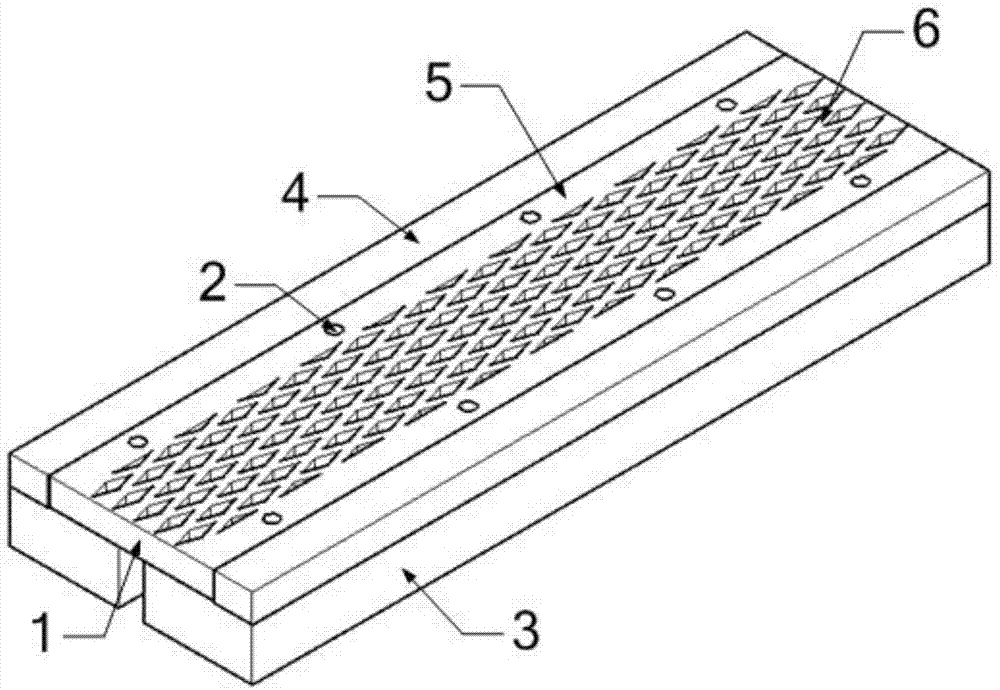

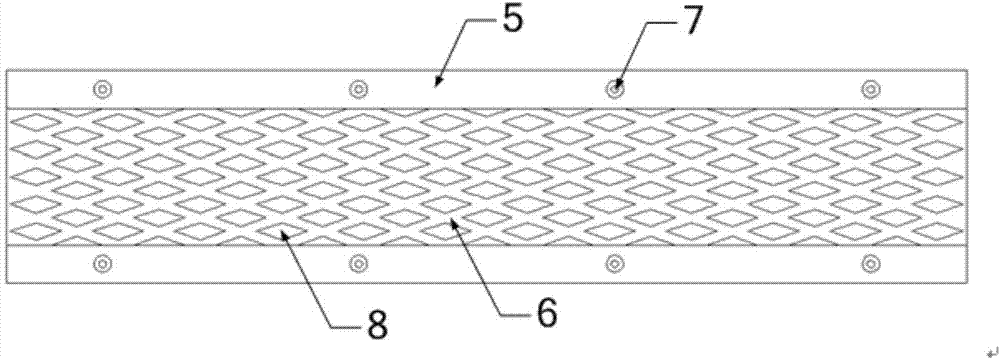

[0018] Such as figure 1 , 2 Shown in and 4, the polymer elastomer expansion joint of the present invention, the polymer elastomer expansion joint 1 is made of polyurethane elastomer, the length is as long as the width of the concrete pavement 3, and the thickness is the same as the pavement layer 4, and is installed on the On the concrete pavement 3, which is flush with the pavement layer 4, the polymer elastomer expansion joint 1 includes a fixed area 5 and a telescopic deformation area 6; the telescopic deformation area 6 adopts a constant cross-section form, and the deformation holes 8 above are diamond-shaped.

Embodiment 2

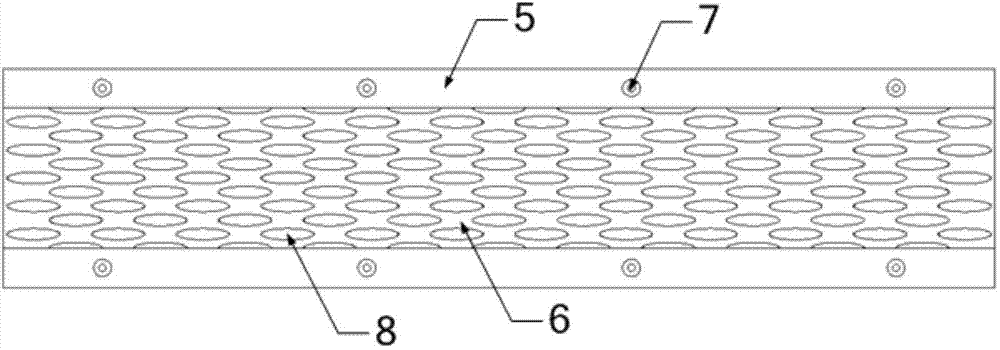

[0020] Such as image 3 and 5 As shown, the polymer elastomer expansion joint of the present invention, the polymer elastomer expansion joint 1 is made of fiber reinforced composite material, the length is as long as the width of the concrete pavement 3, and the thickness is the same as that of the pavement layer 4, and is installed on the concrete by bolts 2 On the road surface 3, which is flush with the pavement layer 4, the polymer elastomer expansion joint 1 includes a fixed area 5 and a telescopic deformation area 6; the telescopic deformation area 6 adopts a variable cross-section form, and the deformation hole 8 above is elliptical.

[0021] The preparation process of the polymer elastomer expansion joints in the above two embodiments is as follows:

[0022] a. Make a mold for the expansion joint of the polymer elastic body first, and reserve the positions such as the deformation hole 8 and the bolt hole 7.

[0023] b. Example 1: Polymer elastomer expansion joint 1 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com