Technology for engine continuous variable valve timing, phase position and lift

A valve timing and variable technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems that the valve phase and lift cannot be changed, and achieve simple structure, increased intake air volume, and smooth intake and exhaust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

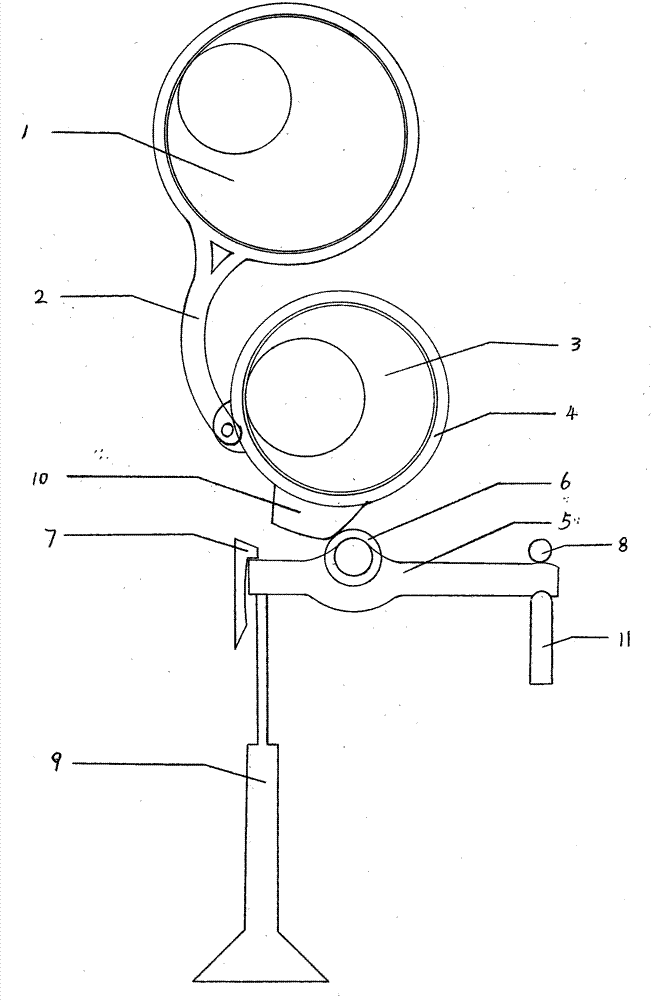

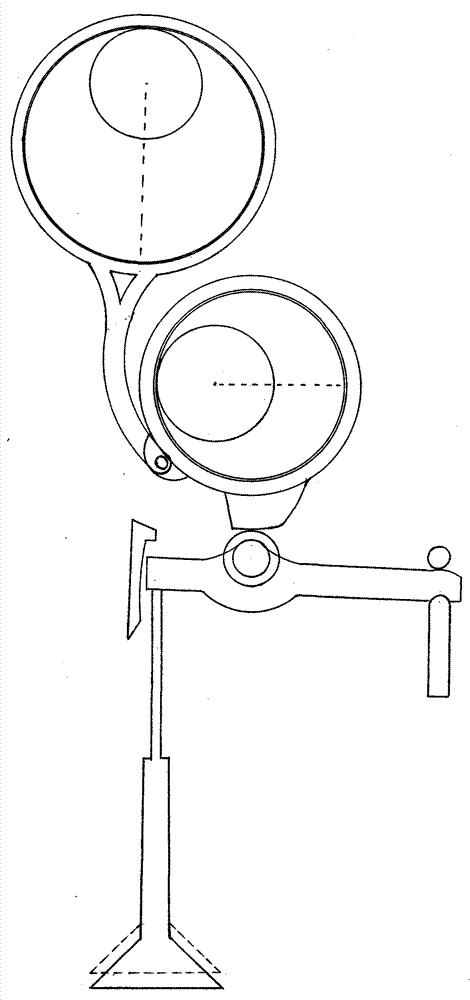

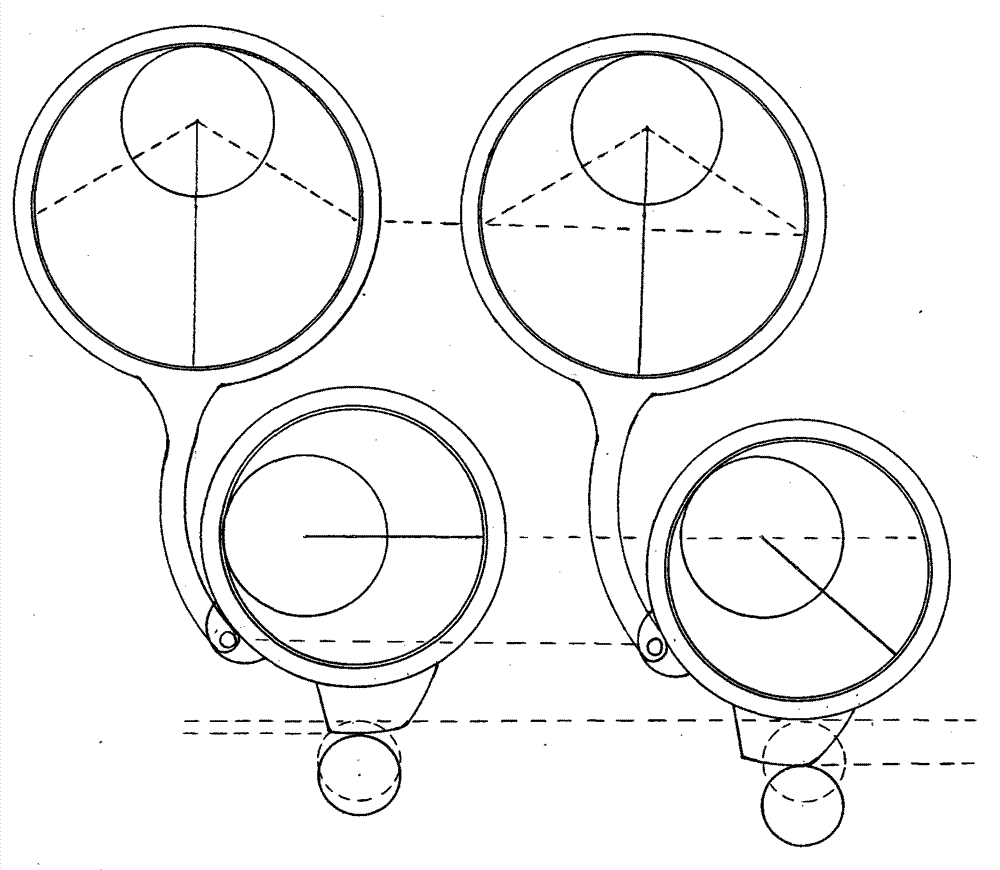

[0017] exist figure 1 Among them, the eccentric camshaft (1) is connected with the connecting rod (2), the shaft sleeve (4) is installed on the eccentric adjustment shaft (3), and the connecting rod (2) is connected with the shaft sleeve (4). The eccentric adjustment shaft (3) is in a static state when it does not need to be adjusted, and when the engine speed rises, it is adjusted according to the speed requirement. The eccentric camshaft (1) is driven by the rod where the small circle is located, driving the eccentric camshaft to rotate, figure 2 The middle eccentric camshaft (1) rotates clockwise to drive the connecting rod (2) to move, and the connecting rod (2) drives the shaft sleeve (4) to move, and the shaft sleeve (4) performs reciprocating motion. exist figure 2 The middle opening convex surface (10) is under the shaft sleeve (4) and reciprocates together with the shaft sleeve. When the opening convex surface (10) moves to the position of the rocker ball (6), it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com