Automatic drainage silencer for vehicle

An automatic drainage and muffler technology, which is applied to muffler devices, exhaust devices, engine components, etc., can solve problems such as corrosion of the outer surface of the muffler shell, corrosion of the muffler by condensed water, and water accumulation at the parking place of the vehicle, so as to improve the low speed. Drainage performance, simple structure, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

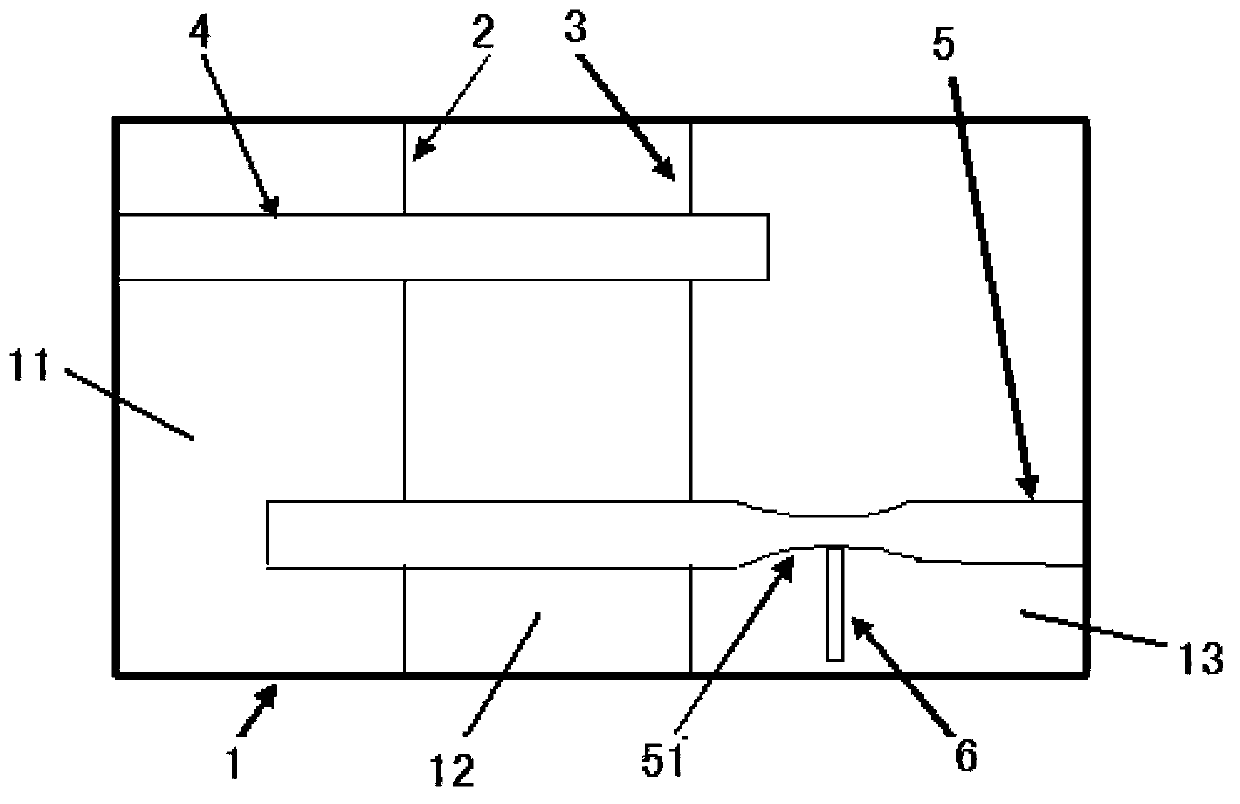

[0014] see figure 1 , the vehicle automatic drainage muffler of the present invention comprises a housing 1, a front baffle 2 and a rear baffle 3 are arranged in the housing, and the front baffle 2 and the rear baffle 3 separate the housing into a front cavity 11, a middle Cavity 12 and rear cavity 13, an air intake pipe 4 straddles the front cavity and the middle cavity and erects on the front baffle and the rear baffle, and an air outlet pipe 5 spans the rear cavity and the middle cavity and erects it on the rear baffle and the front baffle; Including the siphon tube 6 , a section of Venturi tube 51 is arranged in the middle of the air outlet pipe 5 , and the Venturi tube 51 is arranged in the middle of the air outlet pipe located in the rear chamber 13 of the housing. The siphon pipe 6 is connected below the position of the smallest diameter of the Venturi tube 51 and the siphon mouth is close to the bottom plate of the housing downward.

[0015] Both the front baffle 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com