Cam rotor pump for conveying high-viscosity medium

A cam rotor pump, high viscosity technology, applied in the field of rotor pump machinery, can solve the problems of poor versatility of conveying medium, low efficiency of conveying medium, increased maintenance cost, etc., and achieve the effect of benefiting lubrication, prolonging life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

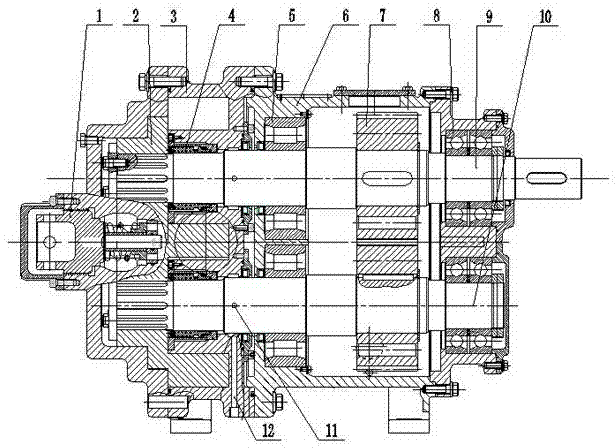

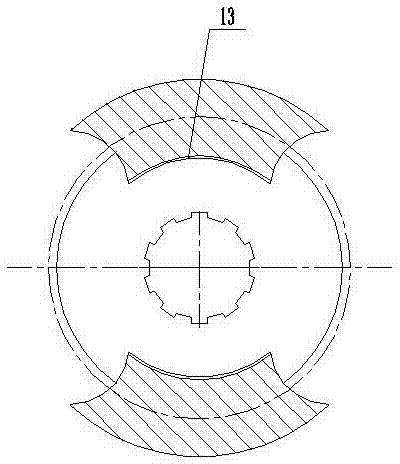

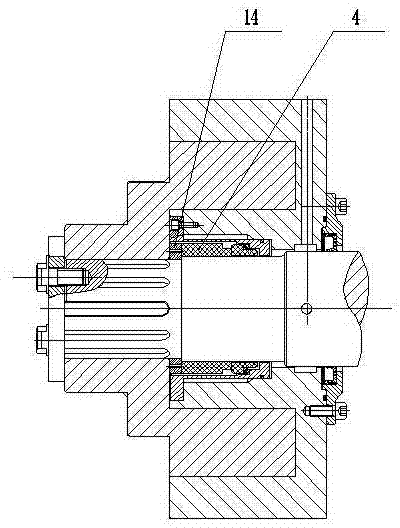

[0013] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the lobe rotor pump for conveying high-viscosity medium includes a pump body 3, a safety valve 1 is provided at the front end of the pump body 3, and the pump body 3 is fixed to the gear box 6 connection, the pump body 3 and the gear box 6 are provided with a driving shaft 9 and a driven shaft 10 in parallel, and the driving shaft 9 and the driven shaft 10 are respectively provided with a rotor 2 and a synchronous gear 7, and the two rotors 2 are arranged perpendicularly to each other. The key is installed at the leftmost end of the two pump shafts, the two synchronous gears 7 mesh with each other, the driving shaft 9, the driven shaft 10 and the pump body 3 are sealed by the mechanical seal 4, the driving shaft 9, the driven shaft 10 and the gearbox The first bearing 5 of the cylindrical roller bearing and the second bearing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com