Multi-dimensional detection amphibious operation pipeline robot

A pipeline robot and operation technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve problems such as affecting the use of pipelines, difficult to carry out inspection and operation, and water flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The core of the present invention is to provide a pipeline robot, which can complete remote detection and operation functions in complex pipeline environments. In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

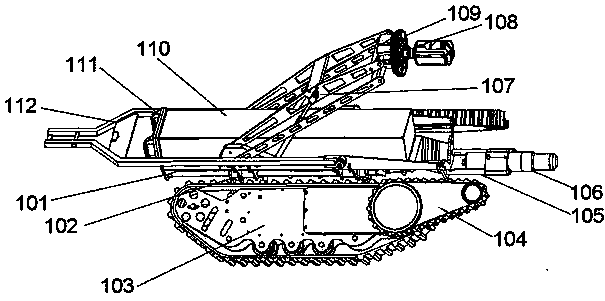

[0041] figure 1It is a schematic diagram of the main structure of the pipeline robot of the present invention. As shown in the figure, the pipeline robot includes: frame 101, left main crawler assembly 103 and right main crawler assembly 103, crawler angle adjustment mechanism 102, front left auxiliary crawler assembly 104 and front right auxiliary crawler assembly 104, sonar fixed Frame 105, sonar probe 106, camera elevating frame 107, camera unit 108, auxiliary light source 109, electronic control box 110, electronic control box drawing door 111 and cable traction frame 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com