LED lamp wick module and LED bulb with the same

An LED wick and LED bulb technology, applied in the field of lighting, can solve the problems of reducing the light intensity of LED bulbs, shortening the service life of LED bulbs, etc., and achieve the effects of improving color rendering index and luminous efficiency, prolonging service life, and large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

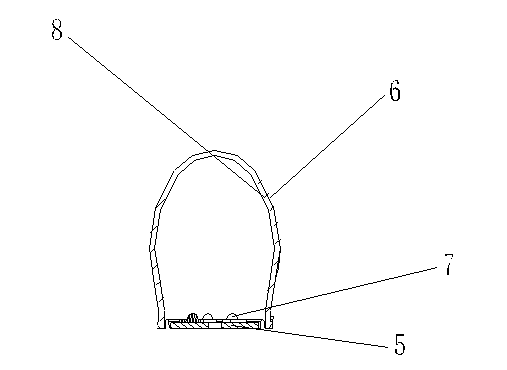

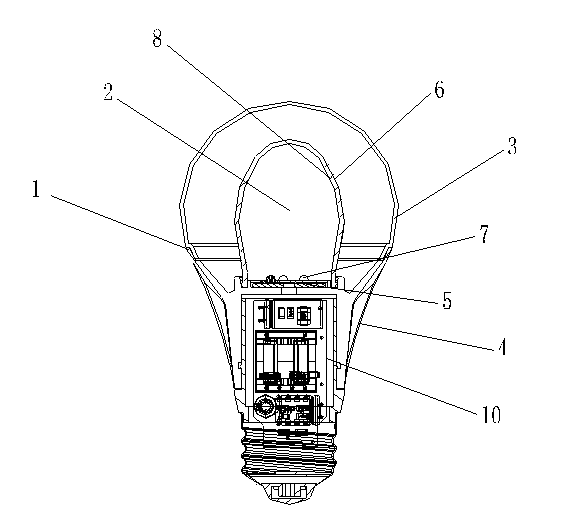

[0019] Such as figure 1 As shown, the part indicated by the label 2 is the LED wick module in this embodiment, which includes a substrate 5 and a wick cover 6 sleeved on the substrate 5. The wick cover 6 is shaped like a cone. There is a blue LED lamp 7, the inner surface of the wick cover 6 is covered with a phosphor layer 8, the wick cover 6 covered with the phosphor layer 8 can expand the light-emitting angle of the LED lamp, and also reduce the light decay of the LED lamp Phenomenon.

[0020] The above phosphor layer 8 is a remote phosphor layer, which can be combined with the blue LED lamp 7 for better fluorescence excitation.

[0021] Such as figure 2 , image 3 As shown, the LED light bulb in this embodiment includes a casing 1, and the casing 1 includes a lampshade 3 and a lamp body 4 that are connected to each other. The connection method between the lampshade 3 and the lamp body 4 can be threaded connection, buckle connection or other methods. The lampshade 3 i...

Embodiment 2

[0026] Others are the same as in Embodiment 1, except that two blue LED lamps are arranged on the substrate 5, the lamp body 4 is made of a ceramic lamp body, and the substrate 5 is made of a ceramic substrate to meet different usage needs.

Embodiment 3

[0028] Others are the same as the content of embodiment 1 or 2, the difference is: as Figure 4 , Figure 5 As shown, the lampshade 3 and the wick cover 6 are candle-shaped, and the center of the lamp body 4 is slightly protruding outward, which can meet different usage needs.

[0029] The working principle of the present invention is introduced below:

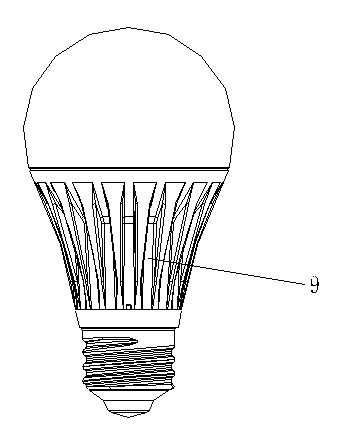

[0030] The wick cover 6 covered with a remote phosphor layer on the inner surface is covered on the blue LED lamp 7, and the combination of the two is used for fluorescent excitation, which replaces the original method of directly covering the blue LED lamp 7 with the phosphor layer, and improves the performance of the LED bulb. The color rendering index and luminous efficiency can reduce the light decay phenomenon caused by traditional LED bulbs and prolong the service life of LED bulbs; the outer surface of the lamp body 4 is uniformly provided with a number of longitudinally opened heat dissipation grooves 9, which increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com