Combined garbage multi-layer high-temperature burning harmless energy device

A high-temperature combustion, combined technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of insufficient heat, heat pollution, energy waste, etc., and achieve the effect of reducing toxic substances, reducing energy waste, and reducing heat pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

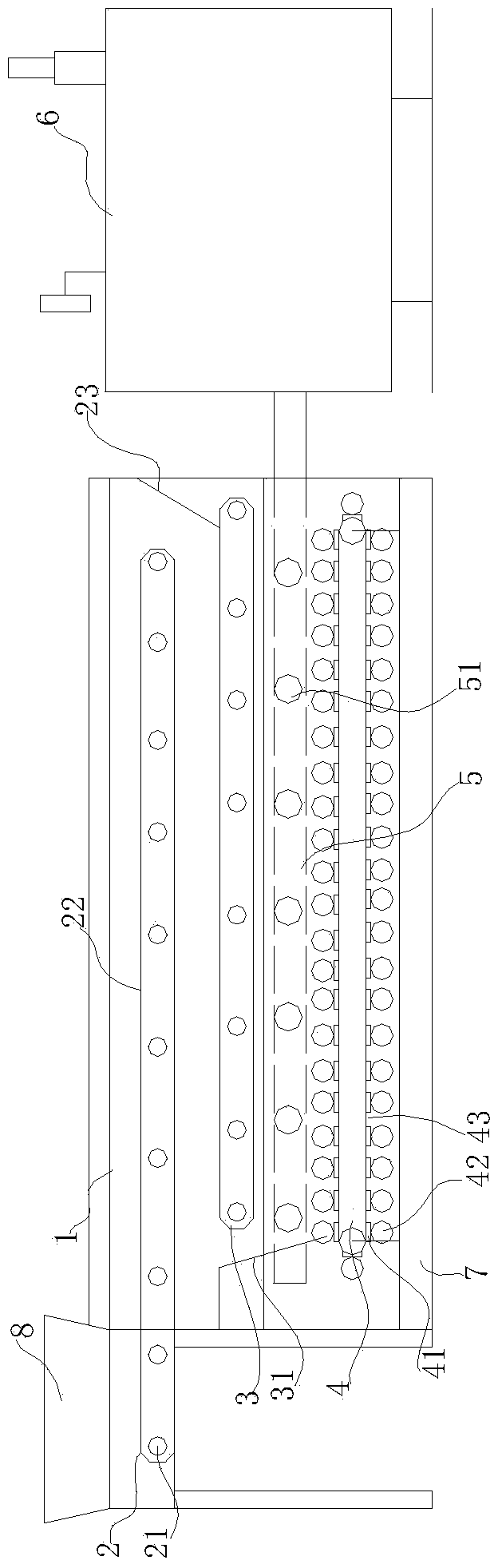

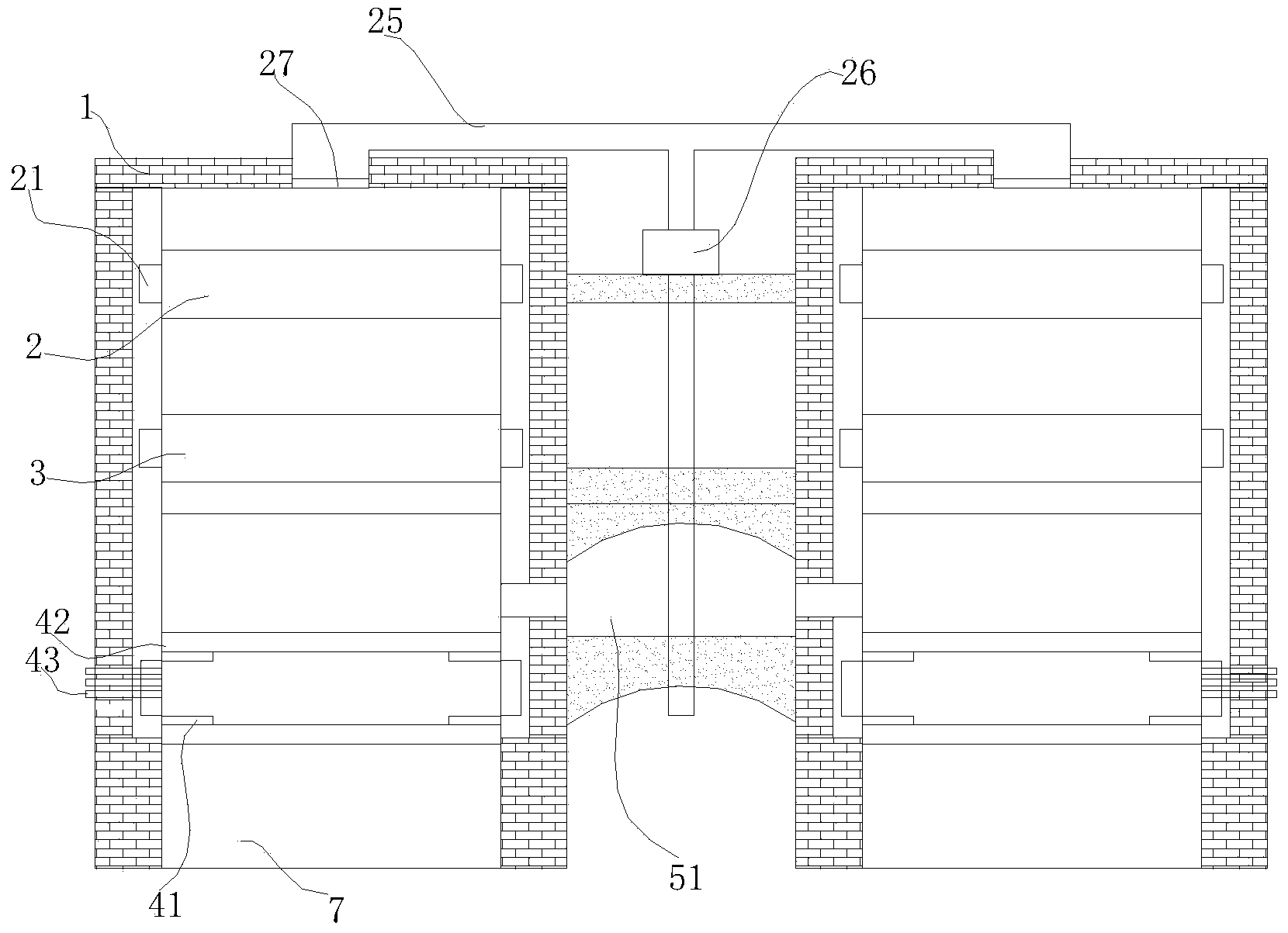

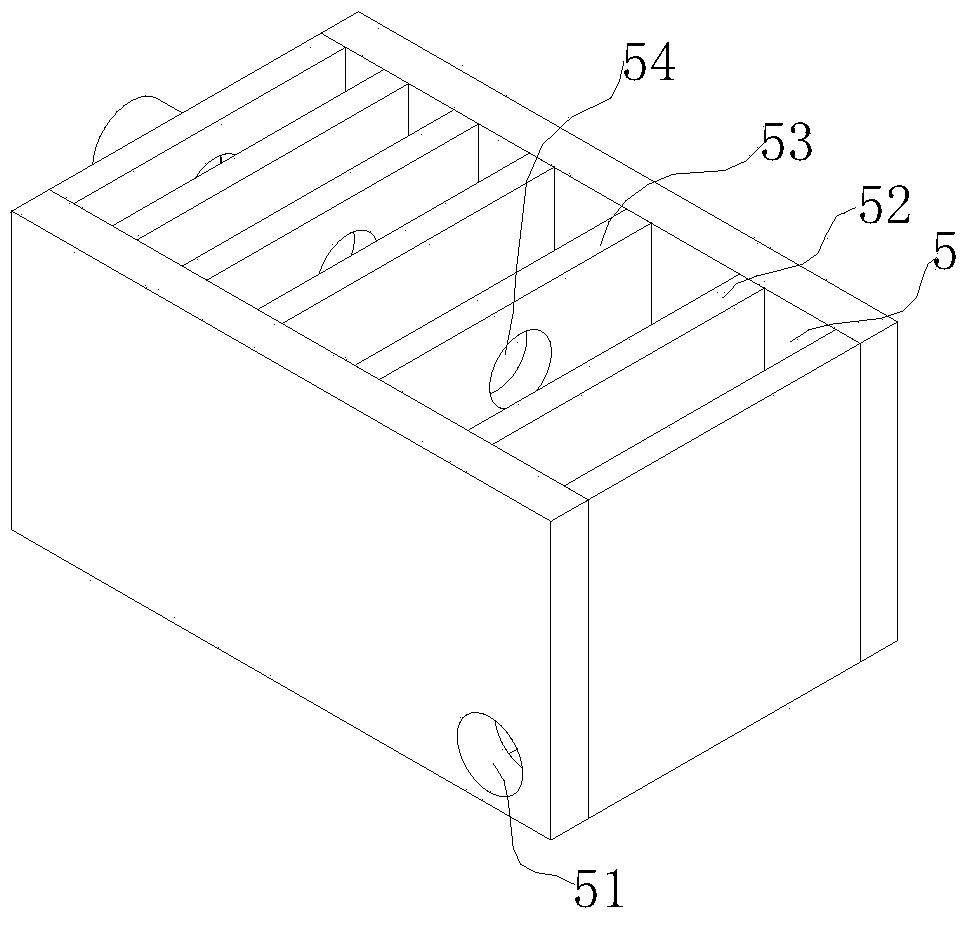

[0021] Example. A combined garbage multi-layer high-temperature combustion harmless energy device, which is composed of Figure 1-4 As shown, it includes two symmetrically arranged multi-layer garbage high-temperature gasification treatment chambers 1, and each garbage high-temperature gasification treatment chamber 1 is sequentially provided with a garbage transmission layer 2, a drying and drainage layer 3, and a garbage gasification treatment chamber 1 from top to bottom. The combustion layer 4 and the ventilation layer 7, the garbage transmission layer 2 is close to the garbage gasification combustion layer 4, the high temperature heat storage gas collection channel 5 is set between the garbage high temperature gasification treatment chamber 1, and the garbage gasification combustion layer is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com