A gas turbine dual-fuel combustor nozzle

A gas turbine and dual-fuel technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as unfavorable flame stability, difficulty in maintaining high-efficiency combustion, and disturbing the flow field of the combustion chamber, so as to avoid the phenomenon of uneven dilution, Improve combustion stability and protect against burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

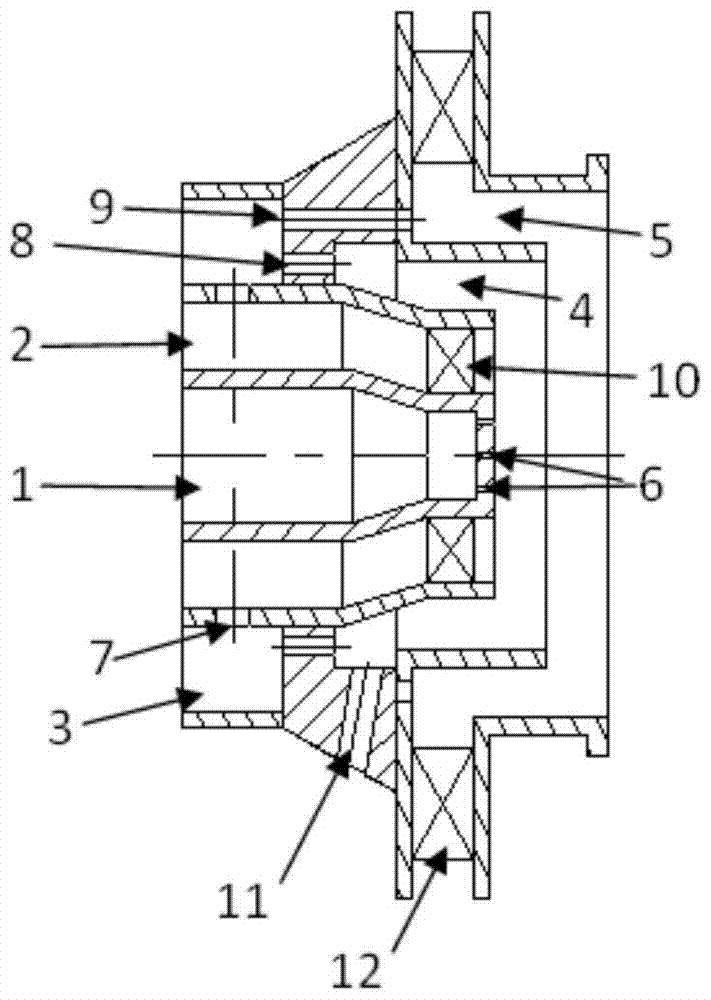

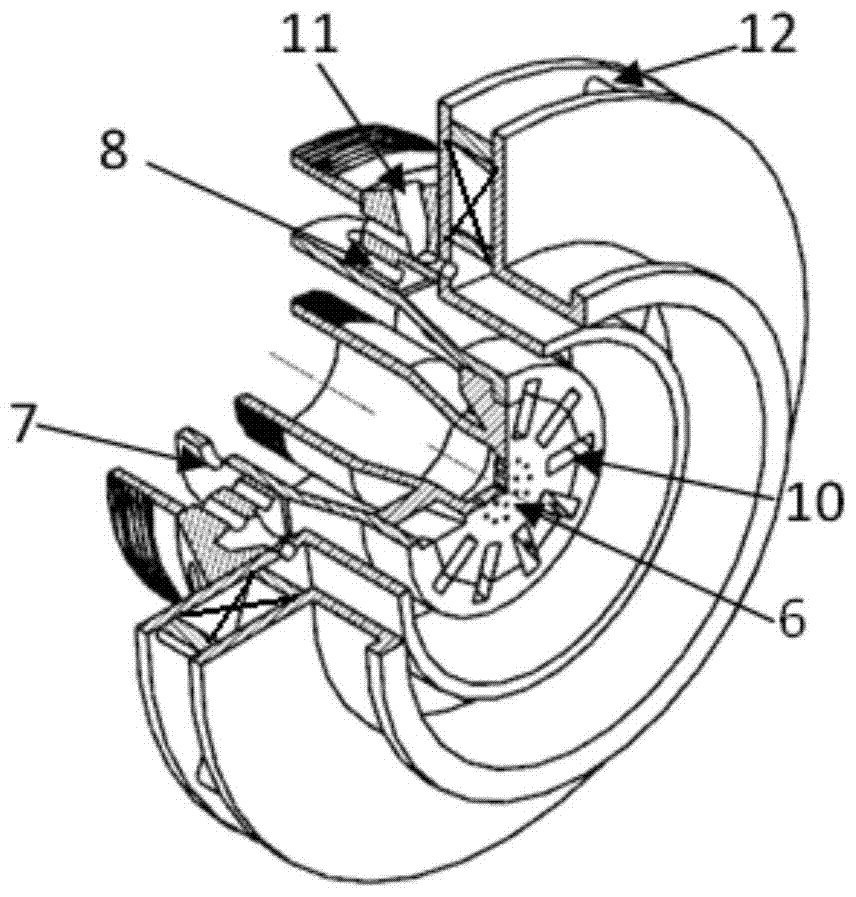

[0019] figure 1 A schematic diagram of the structural principle of a gas turbine dual-fuel combustor nozzle provided by the present invention, the nozzle includes an axial central fuel passage 1 and a peripheral axial annular fuel passage 2 coaxially arranged with the axial central fuel passage 1, and its characteristics In that: outside the peripheral axial annular fuel passage 2, a peripheral axial annular dilution gas passage 3 coaxially arranged with the axial central fuel passage 1 is also arranged; the air passage of the nozzle is also arranged coaxially with the axial central fuel passage 1, and It is divided into a first-level peripheral radial annular air channel 4 and a second-level peripheral radial annular air channel 5 .

[0020] There are dense small holes 6 on the wall surface of the outlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com