Heterogeneous multi-layer crucible

A crucible and heterogeneous technology, applied in the directions of crucibles, crucible furnaces, furnaces, etc., can solve the problems of short service life of crucibles and unfavorable industrial production, and achieve the effect of prolonging service life and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

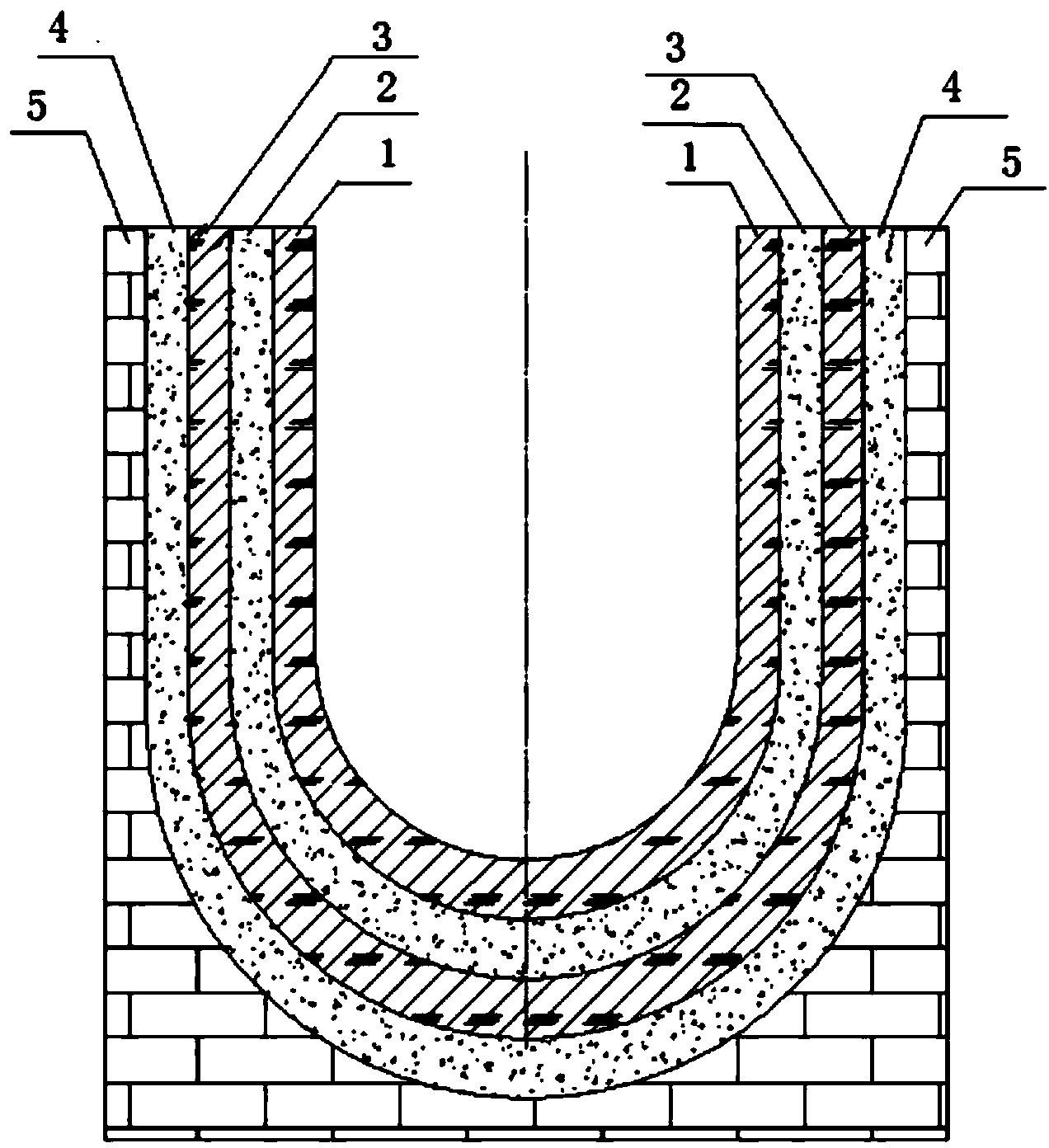

[0017] Such as figure 1 As shown, the heterogeneous multilayer crucible includes a first crucible layer 1, a second crucible layer 3 and a third crucible layer 5, a sand filling layer I2 is between the first crucible layer 1 and the second crucible layer 3, and the second crucible layer Between the layer 3 and the third crucible layer 5 is the sand filling layer II4.

[0018] When in use, the first crucible layer 1 requires corrosion resistance and high temperature resistance, that is, it does not have a physical and chemical reaction with the internally loaded melt, and its melting point is higher than the melting point or boiling point of the internally loaded molten material; In addition to the effects of corrosion and high temperature resistance, the structure needs to be dense so that the molten liquid contained in it does not leak; the third crucible layer 5 is made of a material with a melting point and a thermal expansion coefficient smaller than that of the first cruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com