Battery-pack leakage-liquid detection system

A detection system and battery pack technology, applied in the application of electrical devices to test fluid tightness and other directions, can solve problems such as unreasonable installation and fixing structure, dangerous electronic devices, and live battery boxes, and achieve easy popularization, accurate results, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

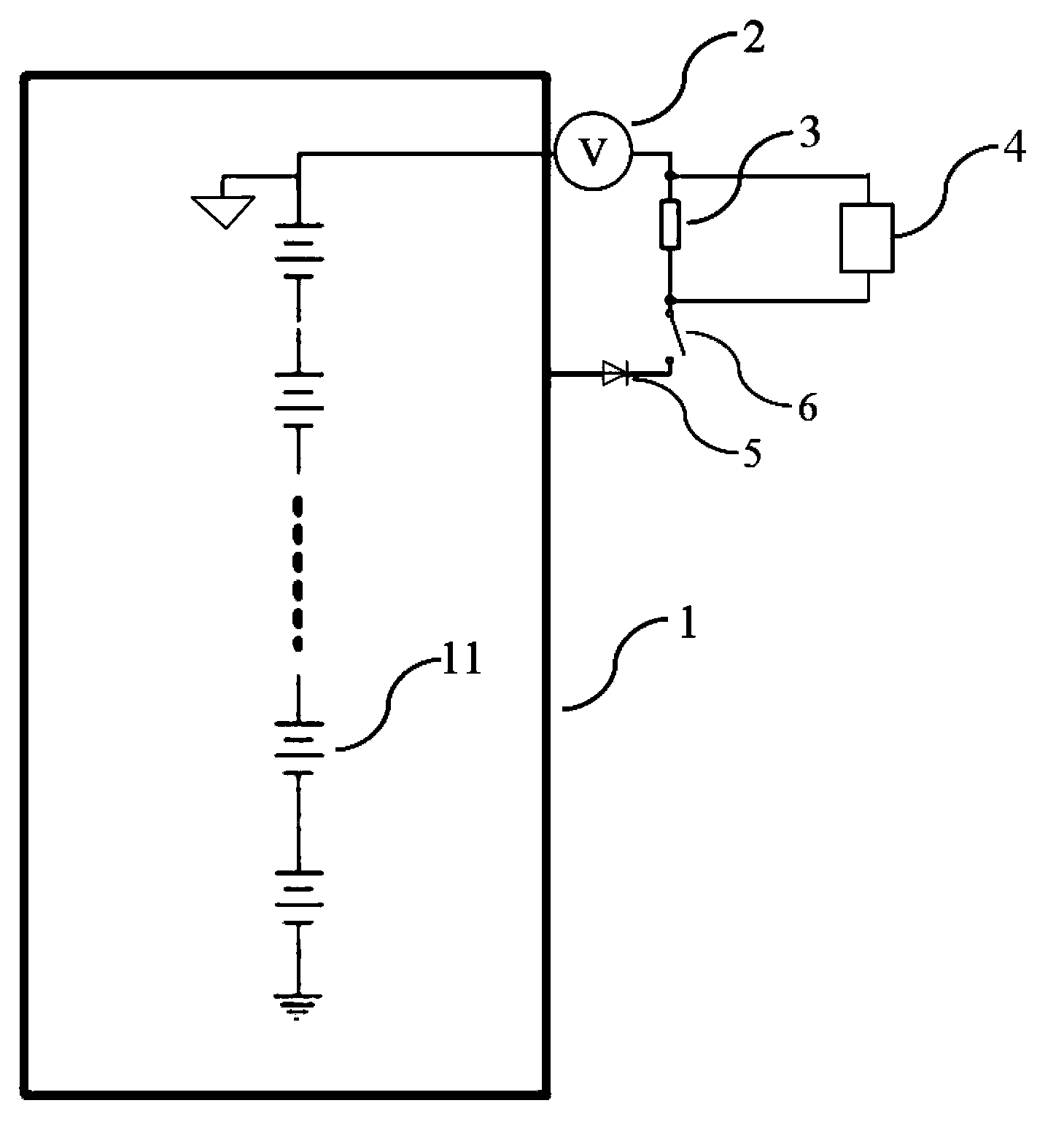

[0026] Such as figure 1 As shown, the battery leakage detection system provided by the present invention includes a metal battery box 1, a battery pack 11, an input power source 2, a load 3, a voltage detection device 4, a unidirectional diode 5 and a detection switch 6. Group 11, battery box 1, input power supply 2, load 3, voltage detection device 4 and unidirectional diode 5 are connected in series, load 3 selects a resistance of 50kΩ; close detection switch 6, when battery pack 11 works normally, nothing happens When there is liquid leakage, the circuit is regarded as an open circuit, and the voltage detection device 4 has no reading or can only detect a small voltage; if the battery pack 11 is working abnormally and leaks, the reading detected by the voltage detection device 4 shows a higher voltage value At this time, it indicates that there is leakage of battery cells in the battery pack 11 and poor insulation.

Embodiment 2

[0028] Such as figure 1 As shown, the battery pack leakage detection system provided by the present invention includes a metal battery box 1, a battery pack 11, an input power source 2, a load 3, a voltage detection device 4, a unidirectional diode 5, and a detection switch 6. 11. The battery box 1, the input power supply 2, the load 3, the voltage detection device 4 and the unidirectional diode 5 are connected in series, and the load 3 selects a resistance of 100kΩ; close the detection switch 6, when the battery pack 11 works normally, no leakage occurs. When liquid, the circuit is regarded as an open circuit, and the voltage detection device 4 has no reading or can only detect a small voltage; if the battery pack 11 works abnormally and leaks, the reading detected by the voltage detection device 4 shows a higher voltage value. At this time, it indicates that a battery cell in the battery pack 11 has leaked and the insulation is poor.

Embodiment 3

[0030] Such as figure 1 As shown, the battery pack leakage detection system provided by the present invention includes a metal battery box 1, a battery pack 11, an input power source 2, a load 3, a voltage detection device 4, a unidirectional diode 5, and a detection switch 6. 11. The battery box 1, the input power supply 2, the load 3, the voltage detection device 4 and the unidirectional diode 5 are connected in series. The load 3 uses a resistance of 300kΩ; close the detection switch 6, when the battery pack 11 works normally, no leakage occurs. When liquid, the circuit is regarded as an open circuit, and the voltage detection device 4 has no reading or can only detect a small voltage; if the battery pack 11 works abnormally and leaks, the reading detected by the voltage detection device 4 shows a higher voltage value. At this time, it indicates that a battery cell in the battery pack 11 has leaked and the insulation is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com