Method for evaluating tobacco alcoholization quality through ultraviolet spectrum

An ultraviolet spectrum and tobacco leaf technology, which is applied in the field of spectrum analysis, can solve the problems of fuzzy index values, large amount of data and high cost, and achieves the effects of simple analysis method, simple operation method and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, in order to illustrate the specific operation steps of the present invention, the method of the present invention is applied to flue-cured tobacco with different aging times and different production areas to evaluate the aging quality. The tobacco leaf that present embodiment adopts is selected from the tobacco leaf sample that tobacco factory is using. The tobacco leaf samples are only used to illustrate the idea of the present invention, and the present invention is not therefore limited to the tobacco leaf samples.

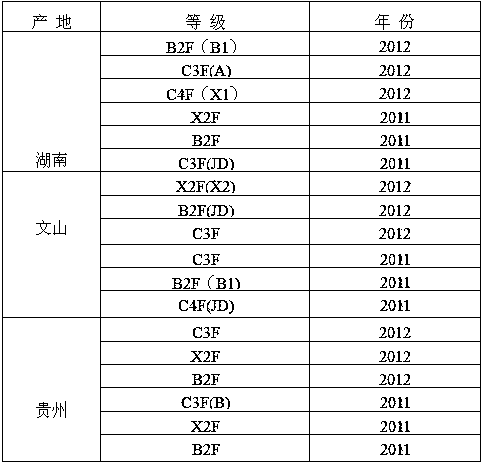

[0024] The samples used are listed in Table 1.

[0025] Table 1 Tobacco leaf samples from different producing areas and aging time

[0026]

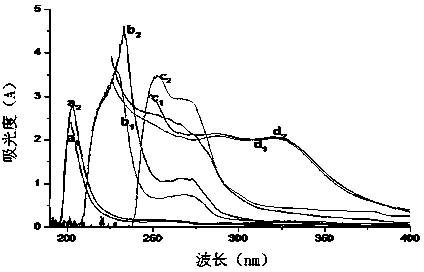

[0027] (1) Preparation of the test solution: Accurately weigh 0.1 g of different tobacco leaf samples dried to constant weight, sequentially extract with 25 ml of petroleum ether, 25 ml of chloroform, 50 ml of absolute ethanol, and 50 ml of water for 1 hour, filter, petroleum ether extract, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com