cmos MEMS capacitive humidity sensor

A humidity sensor, capacitive technology, applied in the direction of material capacitance, etc., can solve the problems of difficult standardization, expensive processing cost, complicated process, etc., and achieve easy batch manufacturing, good temperature characteristics and long-term stability, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

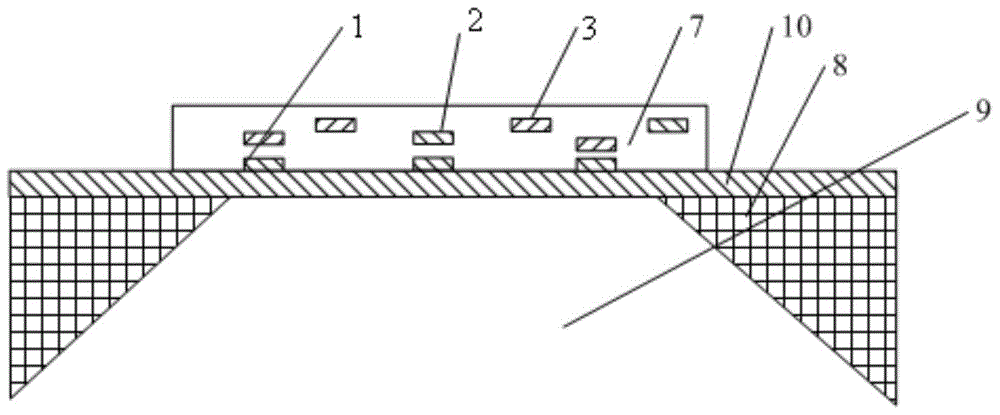

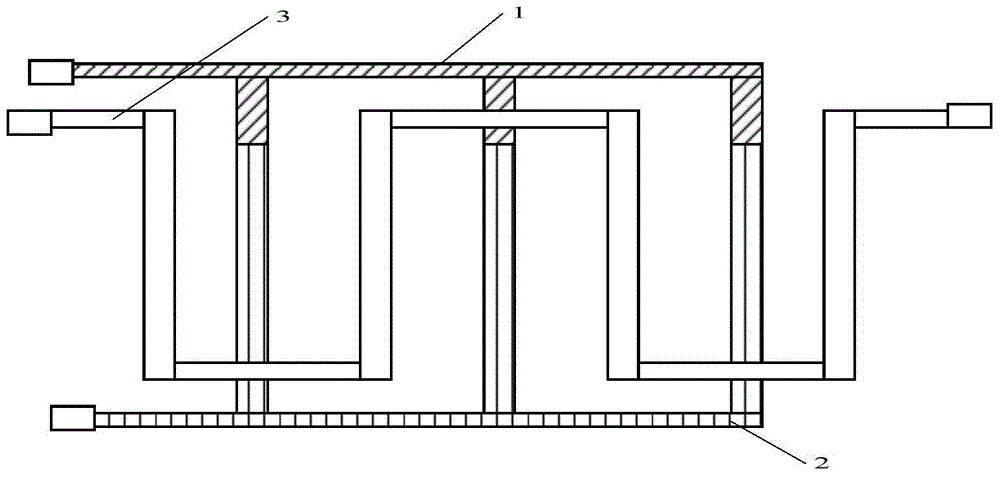

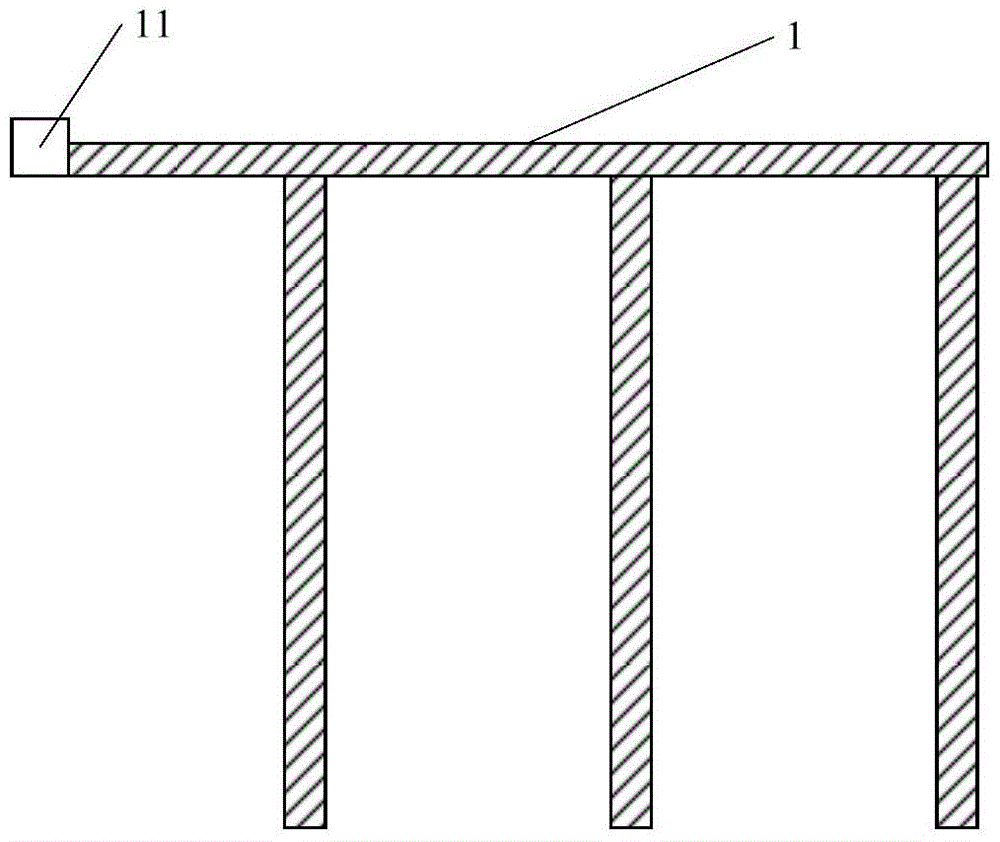

[0017] like figure 1 , figure 2 As shown: the CMOS MEMS capacitive humidity sensor includes an interdigitated upper electrode 2 and an interdigitated lower electrode 1, and the lower electrode 1 is drawn out from the lower electrode pad 11 and passes through SiO 2 The oxide layer 10 is disposed on the same surface of the silicon substrate 8, the upper electrode 2 is led out from the upper electrode pad 21 and is located above the lower electrode 1, and the fingers of the upper electrode 2 and the fingers of the lower electrode 1 overlap in the height direction Fill the humidity sensitive medium 7 between the upper electrode 2 and the lower electrode 1, between the fingers of the upper electrode 2, and the fingers of the lower electrode 1; above the upper electrode 2, press the welding block 31 by an aluminum strip Lead out the aluminum strip 3, the aluminum strip 3 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com