A method for quantitative detection of nugget cracks using the energy equivalent of acoustic emission signals during resistance spot welding

An acoustic emission signal and resistance spot welding technology is applied in the field of quantitatively detecting nugget cracks by using the energy equivalent of acoustic emission signals in the resistance spot welding process, which can solve the problem that the nugget nucleation process cannot be directly observed and judge the quality of resistance spot welding solder joints. Difficulties, serious damage to the quality of solder joints, etc., to achieve the effects of low design and manufacturing costs, simple evaluation methods, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The workpiece to be welded is the lap joint of two aluminum alloy sheets with a thickness of 2 mm. The main welding process parameters used are: the welding current is 22000A, the welding current duration is 8 cycles, and the electrode pressure is 0.15MPa.

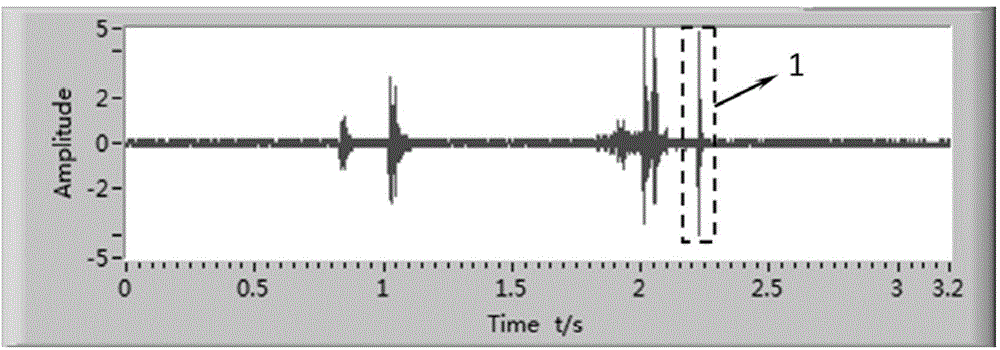

[0037] During welding, the structural load acoustic emission signal of the resistance spot welding process is collected in real time, and the dynamic curve of the structural load acoustic emission signal is drawn by the analysis software, such as figure 1 shown.

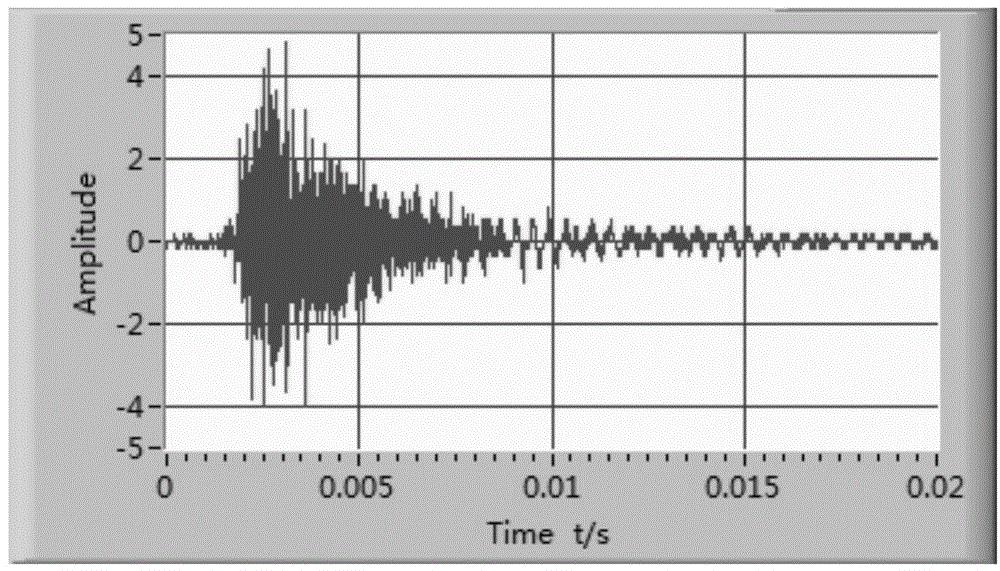

[0038] Different stages of the welding process can be identified from the waveform diagram, and the crack signal 1 can be extracted, such as figure 2 shown.

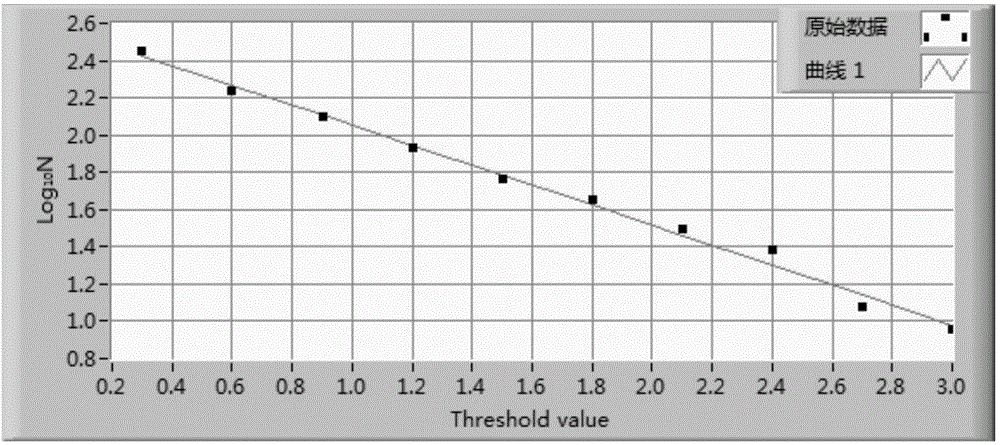

[0039] Statistical analysis of the amplitude distribution of crack acoustic emission signal pulses. According to this distribution, the magnitude of magnitude is divided into 10 levels, namely M 1=0.3, M 2 =0.6, M 3 =0.9, M 4 =1.2, M 5 =1.5, M 6 =1.8, M 7 =2.1, M 8 =2.4, M 9 =2.7, M 10 ...

Embodiment 2

[0044] The workpiece to be welded is the lap joint of two aluminum alloy sheets with a thickness of 2 mm. The main welding process parameters used are: the welding current is 22000A, the welding current duration is 8 cycles, and the electrode pressure is 0.15MPa.

[0045] During welding, the structural load acoustic emission signal of the resistance spot welding process is collected in real time, and the dynamic curve of the structural load acoustic emission signal is drawn by the analysis software, such as Figure 5 shown.

[0046] Different stages of the welding process can be identified from the waveform diagram, and the crack signal 1 can be extracted, such as Image 6 shown.

[0047] Statistical analysis of the amplitude distribution of crack acoustic emission signal pulses. According to this distribution, the magnitude of magnitude is divided into 10 levels, namely M 1 =0.3, M 2 =0.6, M 3 =0.9, M 4 =1.2, M 5 =1.5, M 6 =1.8, M 7 =2.1, M 8 =2.4, M 9 =2.7, M 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com