Battery voltage automatic test screening device and method thereof

An automatic detection and screening device technology, applied in the direction of measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve the problems of physical exertion, poor contact between test leads and battery terminals, and low accuracy, so as to avoid inaccurate results, Avoid poor contact and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

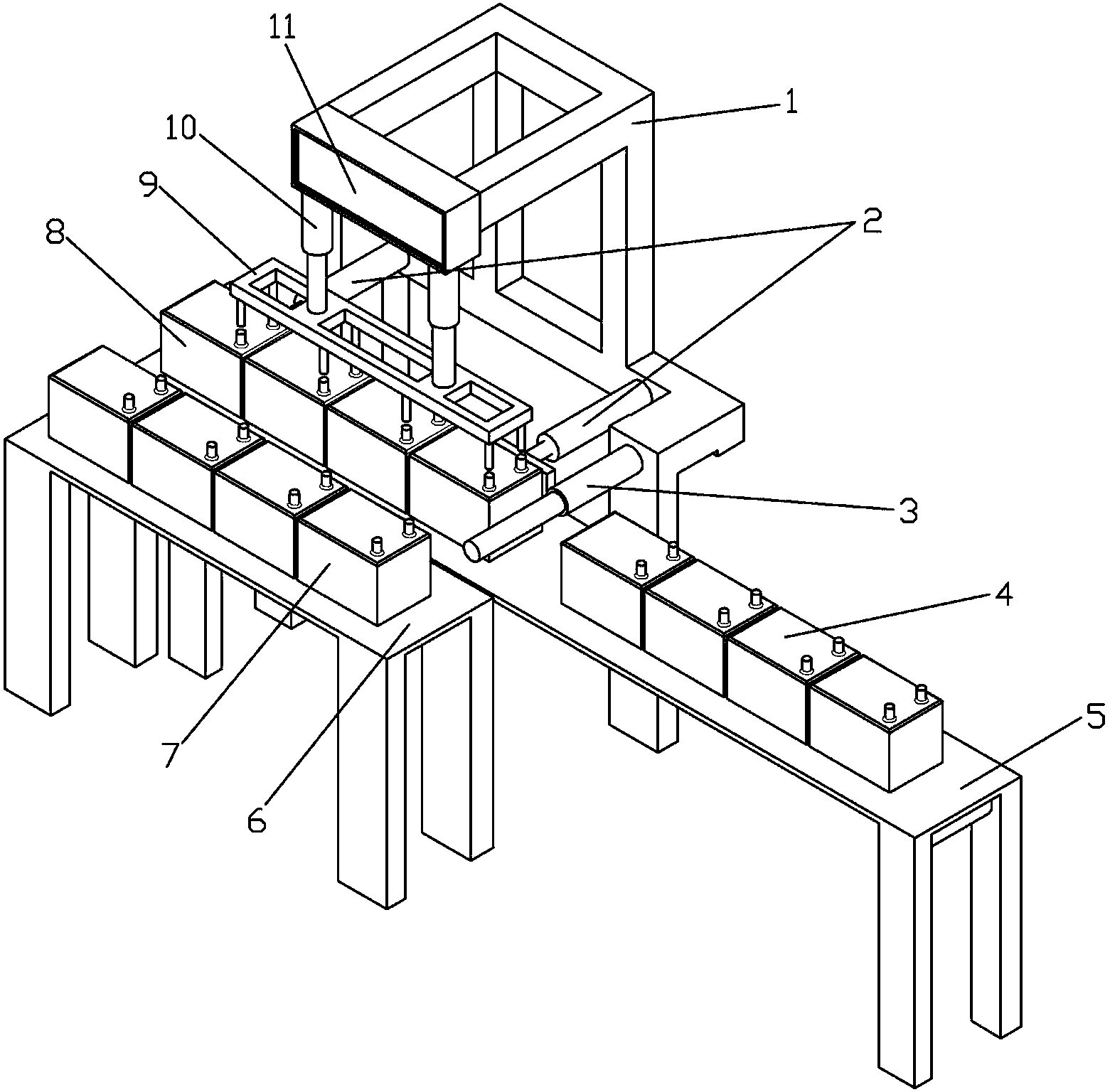

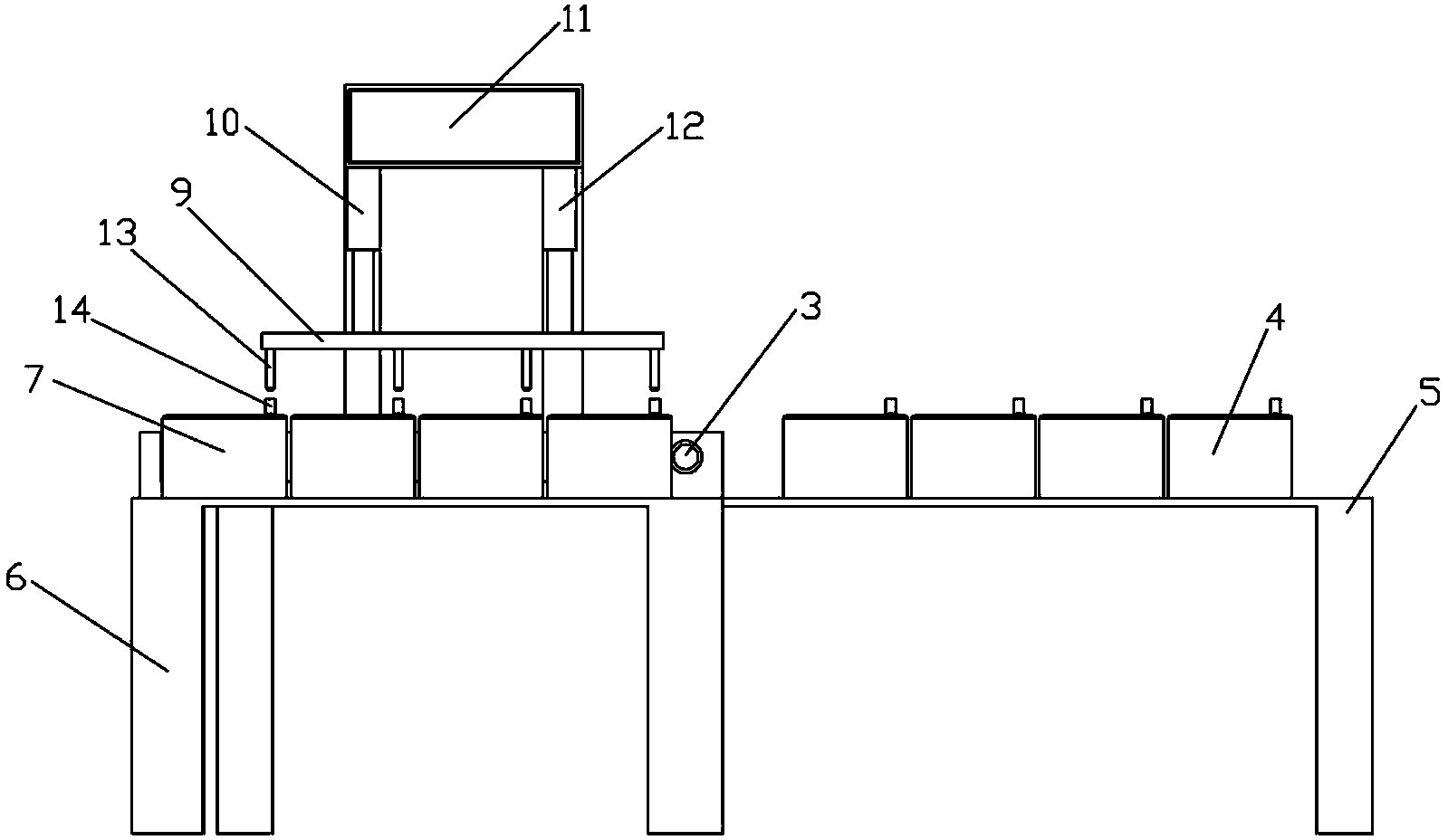

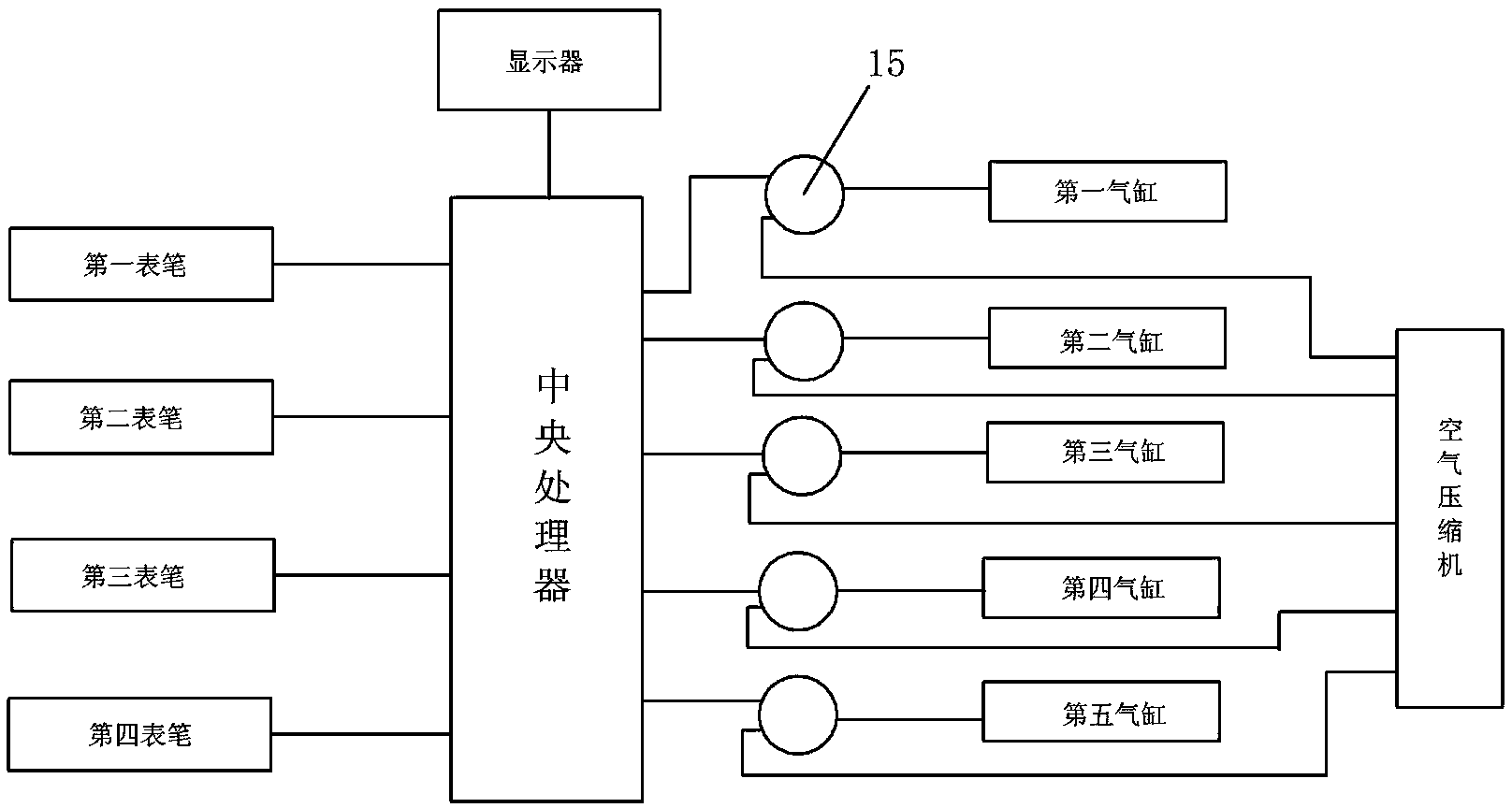

[0023] Embodiment 1: A battery voltage automatic detection and screening device, including a transmission platform, a placement platform and a detection and screening mechanism, the detection and screening mechanism includes a support frame 1, the support frame is set on one side of the transmission platform 5, and the placement platform 6 is located on the same side as the transmission platform 5. On the other side of the transmission table corresponding to the support frame, a test lead holder 9 is arranged on the support frame perpendicular to the horizontal surface of the transfer table, and multiple sets of positive and negative test leads for detecting the positive and negative terminals of the battery are arranged on the test lead holder. Connector 13, the detection signals of the multiple groups of positive and negative test lead joints are sent to the central processing unit for calculation through the input end of the central processing unit, and the test lead frame is...

Embodiment 2

[0027] Embodiment 2: a method for automatic detection and screening of battery voltage, comprising the following steps:

[0028] Step 1: Place the battery to be tested on the transfer table, start the transfer table, air compressor and central processing unit, the third cylinder starts and extends the piston rod, when the battery to be tested runs to the third cylinder along with the transfer table When the piston rod is in the position, it is blocked by the piston rod.

[0029] Step 2: Start the first cylinder and the second cylinder, and the piston rods of the first cylinder and the second cylinder are stretched out, thereby pushing the test lead holder to move down until it contacts the positive and negative terminals of the battery for voltage detection.

[0030] Step 3: The detected voltage signals are transmitted to the central processing unit, and the central processing unit performs comparison calculations on the detected voltage signals, and the detection data is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com