A conveying roller table used in a fully automatic factory test system for motors

A factory test and conveying roller technology, which is applied in the field of motor manufacturing, can solve the problems of the lack of protection system of the roller line system, the out-of-synchronization of the running speed of the roller line, and endanger the personal safety of operators, etc. The effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

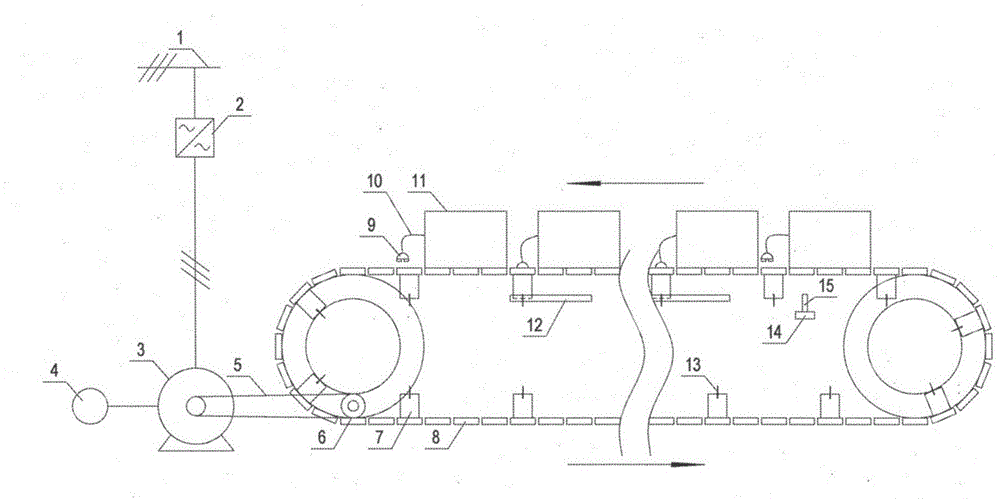

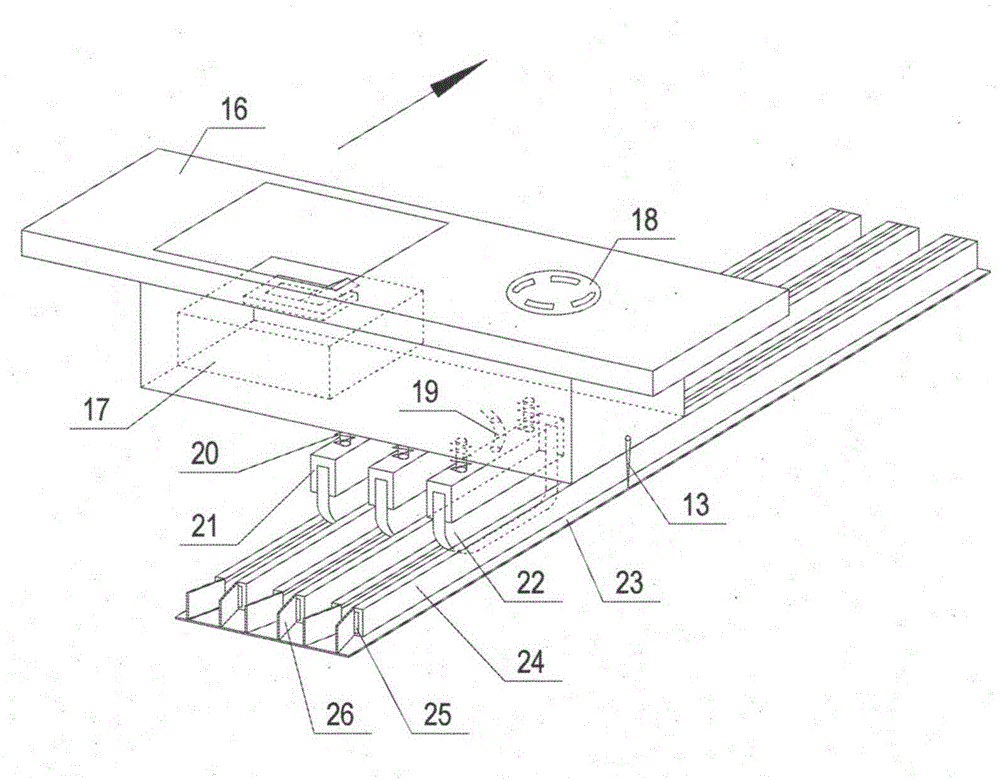

[0019] Such as figure 1 As shown, a conveyor roller table used in a fully automatic factory test system for motors provided by the present invention includes: a power bus 1, a drive frequency converter 2, a drive motor 3, a photoelectric encoder 4, a drive belt 5, and a roller table line drive wheel 6. Power transmission conveying board 7, ordinary conveying board 8, plug 9, motor power transmission cable 10, tested motor 11, bronze slot 12, position probe 13, photoelectric switch bracket 14, photoelectric switch 15.

[0020] The crawler structure is connected by the power transmission conveying plate 7 and the ordinary conveying plate 8. The drive unit drives the crawler structure to run in a cycle. N ordinary conveying plates 8 connected end to end and a power transmission conveying plate 7 form a motor station. , the length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com