Power supply service life detection method and system

A detection method and detection system technology, applied in the detection field, can solve the problem of inaccurate life time of the power supply, and achieve the effect of facilitating maintenance and replacement, improving accuracy, and reliable data information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various embodiments of the power supply life detection method and system of the present invention will be described in detail below.

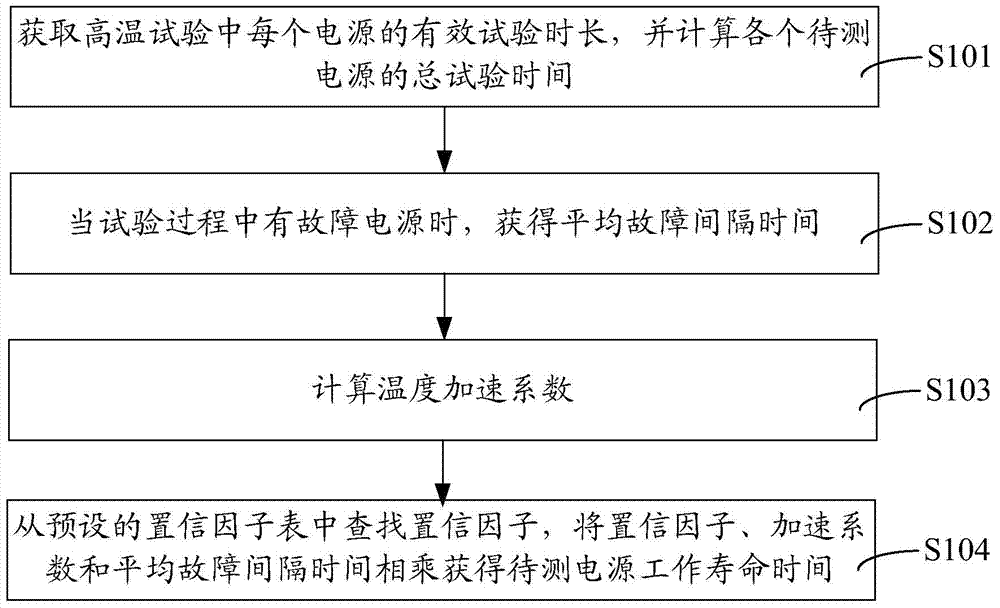

[0021] like figure 1 As shown, it is a schematic flow chart of an embodiment of the power supply life detection method of the present invention, including:

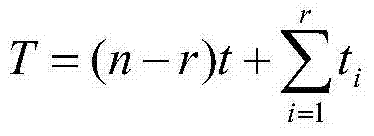

[0022] Step S101: Obtain the effective test duration of each power supply in the high temperature test, and calculate the total test time of each power supply under test; wherein, the high temperature test is a test in which multiple power supplies of the same type under test are operated at a preset high temperature;

[0023] The high temperature test (also called the reliability test) can be carried out under simulated environmental stress conditions, using the high temperature acceleration method, and the acceleration temperature should be higher than the actual operating temperature of the circuit. The accelerated temperature should have a reasonable range, so that the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com