Improvement method of man-machine interface in digital control room of nuclear power plant

A human-machine interface, nuclear power plant technology, applied in the field of control, can solve problems affecting unit safety, etc., and achieve the effect of improving control ability, reducing differences in operating consequences, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below.

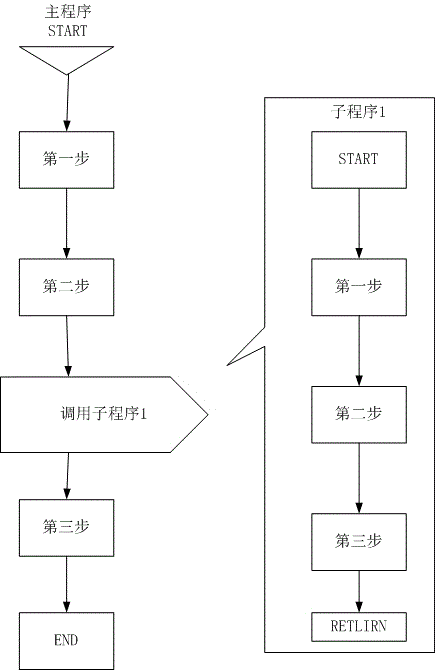

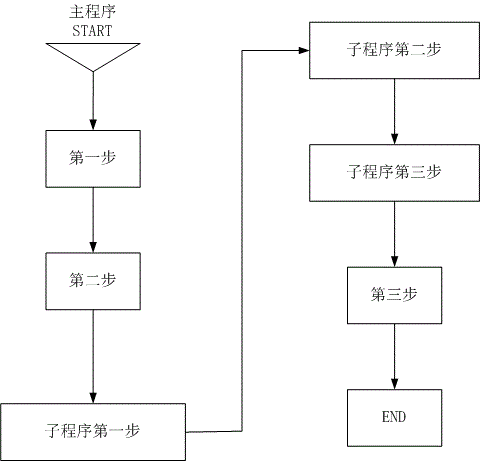

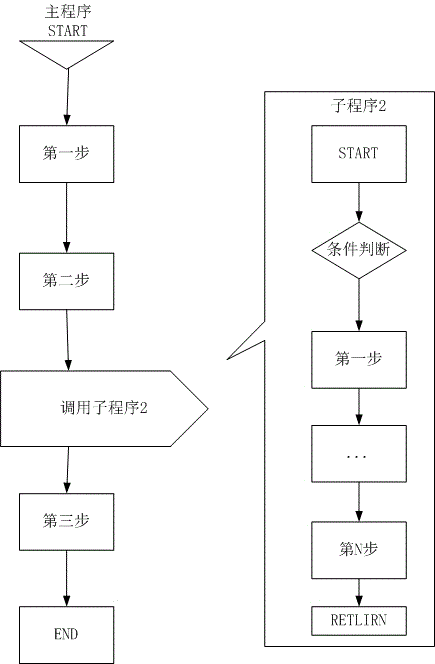

[0019] This improvement method of man-machine interface in digital control room of nuclear power plant includes the following steps: A. Select a simulator with the same hardware facilities as the on-site control system of nuclear power plant as the operating equipment for the improvement work; B. Use the same simulator as the on-site control system The control platform and software language are used to ensure synchronization with the on-site control system, and the control system is a digital control system; C. Improve the man-machine interface of the control system on the simulator, and the man-machine interface adopts an incentive simulation method; D .Test and verify the improved control system on the simulator to determine the improvement effect and make necessary modifications; E. Install it in the on-site control system to complete the improvement of the on-site equipment.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com