Single-wire transmission circuit and method of LED (Light-Emitting Diode) display module single-point correction data

A technology of LED display and display module, applied in static indicators, instruments, etc., can solve the problems of affecting the appearance of the cabinet and increasing the difficulty of wiring, so as to make up for the difference in brightness and chromaticity, reduce maintenance time, and restore use as soon as possible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

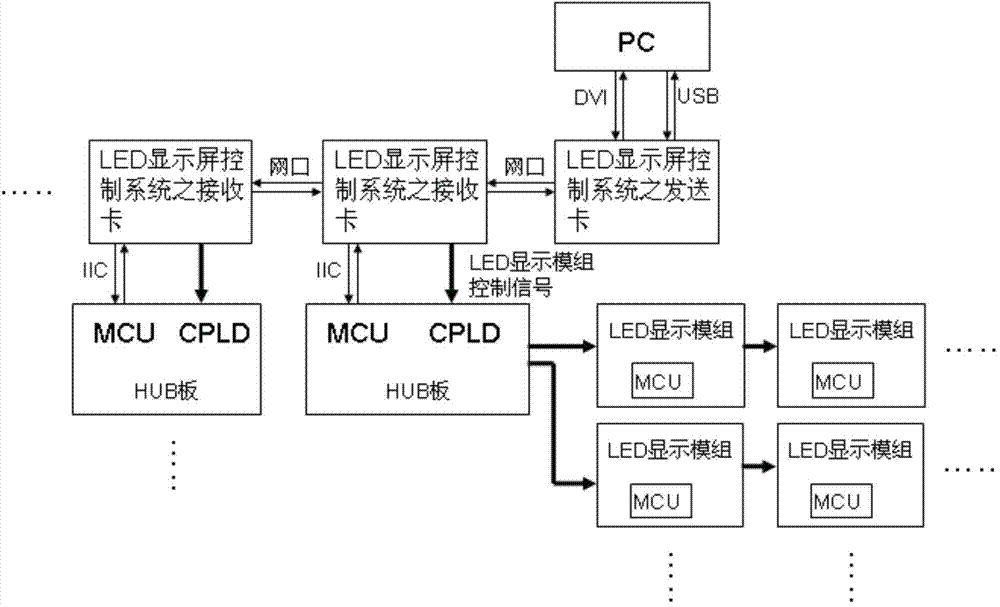

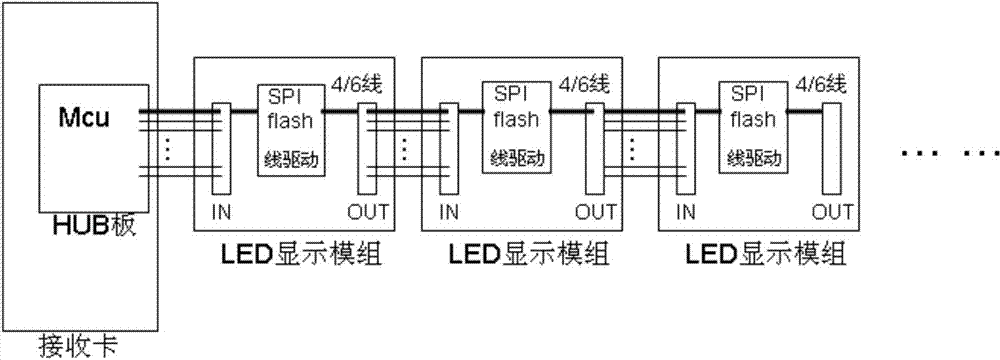

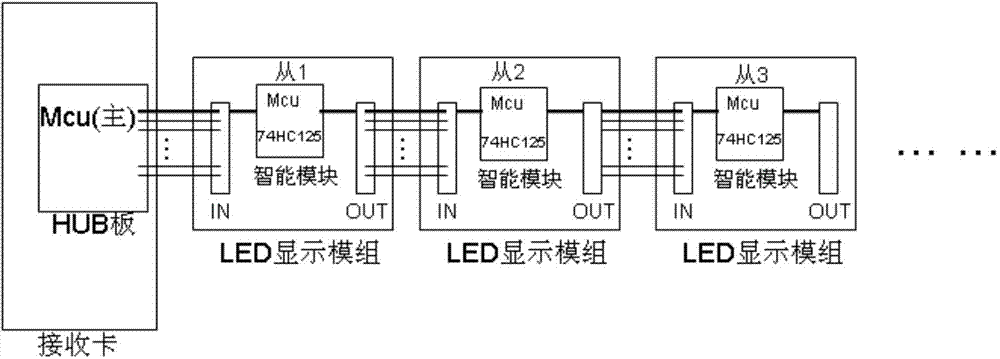

[0030] Such as image 3 , 4 The single-line transmission circuit of the single-point correction data of the LED display module shown includes the LED display module and the HUB board with the main MCU of model STC11L08XE. The LED display module includes LED and constant current driver IC, the HUB board and the LED The receiving card of the display control system is connected, and the receiving card of the LED display control system provides control signals that can be displayed normally to the LED display module. The HUB board includes the main MCU and CPLD. The function of the main MCU is to parse from the I 2 The command of the C bus identifies the corresponding slave MCU, and transmits the single-point calibration data with the slave MCU through the serial port. The function of the CPLD is to control the direction of data flow, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com