Overhead bare stranded wire easy to recognize

An easy-to-identify and twisted wire technology, applied in conductors, insulated cables, electrical components, etc., can solve problems such as difficulty in ensuring smoothness, smoothness, indiscernibility, and erasing of sprayed objects, and achieves convenient quality traceability, circulation, and difficulty. the effect of erasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

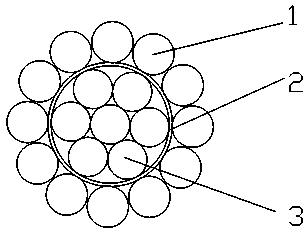

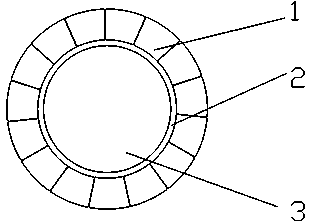

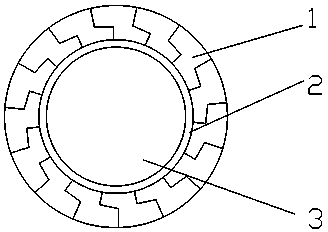

[0015] The invention provides an easily identifiable overhead bare stranded wire, which includes an inner layer stranded wire 3 and an outermost layer stranded wire 1, the inner layer stranded wire is covered with a layer of metal foil 2, and a permanent identification mark is applied on the metal foil . Specifically, there is a layer of metal foil 2 with a permanent identification mark between the inner layer stranded wire 3 and the outermost layer stranded wire 1 .

[0016] The metal foil 2 can be wound around or longitudinally wrapped, one is preferably longitudinally wrapped. The applied permanent identification mark can be engraved or spray printed, one is preferably spray printed. The color ribbon dragged between the metal foil and the inner stranded wire or the permanent identification mark with color is used to identify the phase sequence of the overhead bare stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com