Packaging structure and packaging method of integrated common mode choke

A technology of common-mode inductors and packaging methods, which is applied in the direction of circuits, electrical components, and electric solid-state devices, can solve the problems of large loss of common-mode inductors, high production costs, and large volume, so as to reduce the loss of common-mode inductors and improve production. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

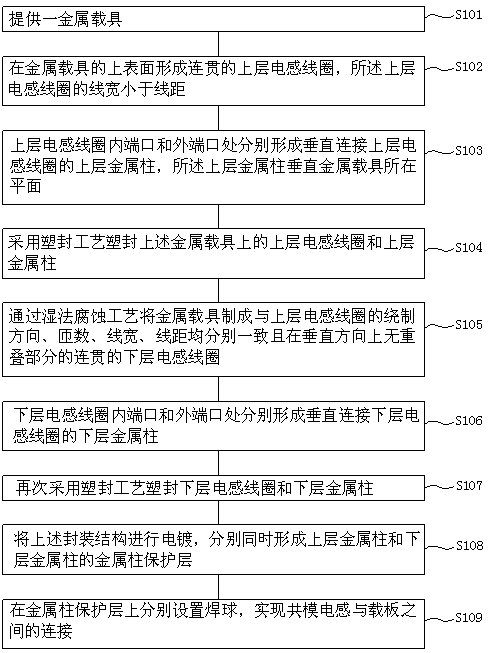

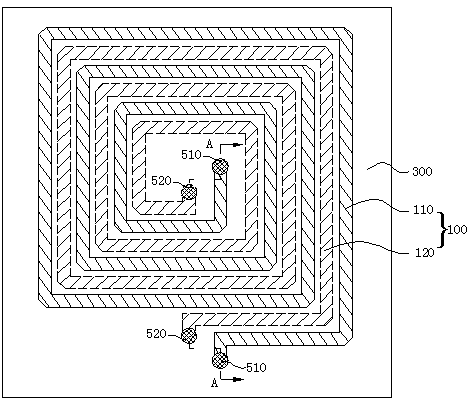

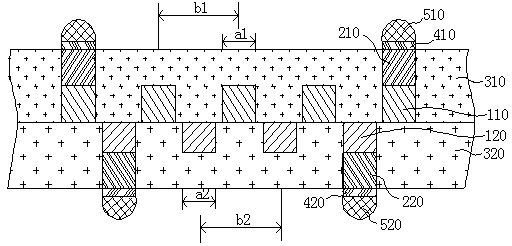

[0068] see figure 1 , a packaging method for integrating common mode inductors of the present invention is formed by a semiconductor packaging process, including the following process flow:

[0069] Executing step S101: providing a metal carrier;

[0070] Executing step S102: forming a continuous upper-layer inductive coil on the upper surface of the metal carrier, the line width of the upper-layer inductive coil being smaller than the line pitch;

[0071] Executing step S103: forming upper-layer metal pillars vertically connected to the upper-layer inductor coil at the inner port and outer port of the upper-layer inductor coil, and the upper-layer metal pillars are perpendicular to the plane where the metal carrier is located;

[0072] Executing step S104: using a plastic sealing process to plastic seal the upper inductor coil and the upper metal column on the metal carrier;

[0073] Executing step S105: making the metal carrier into a coherent lower layer inductor coil wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap