Advanced peak ballast

A technology of ballast and pinnacle, which is applied in the field of advanced pinnacle ballast, which can solve the problems of increasing copper resistance, unfavorable energy saving, large magnetic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

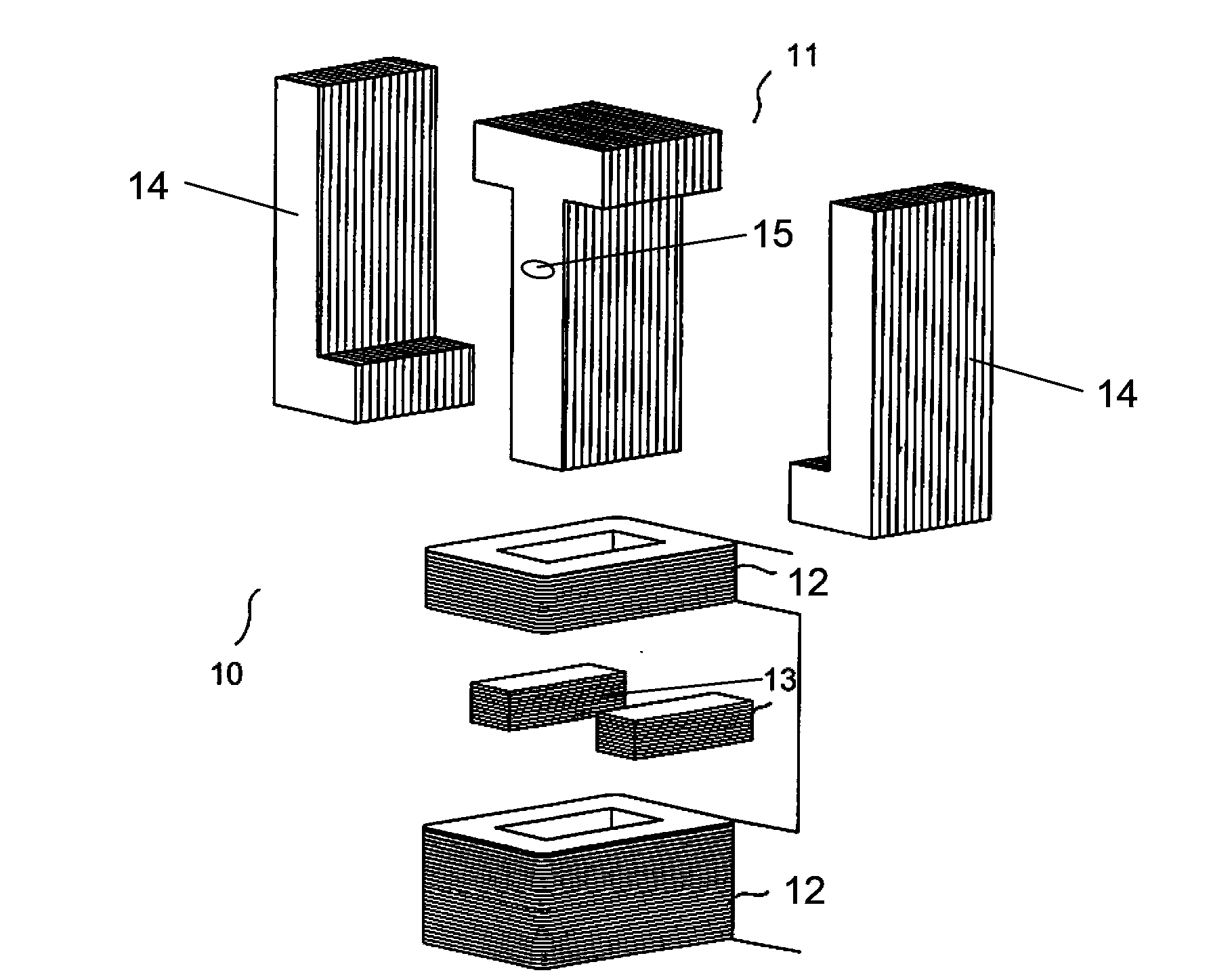

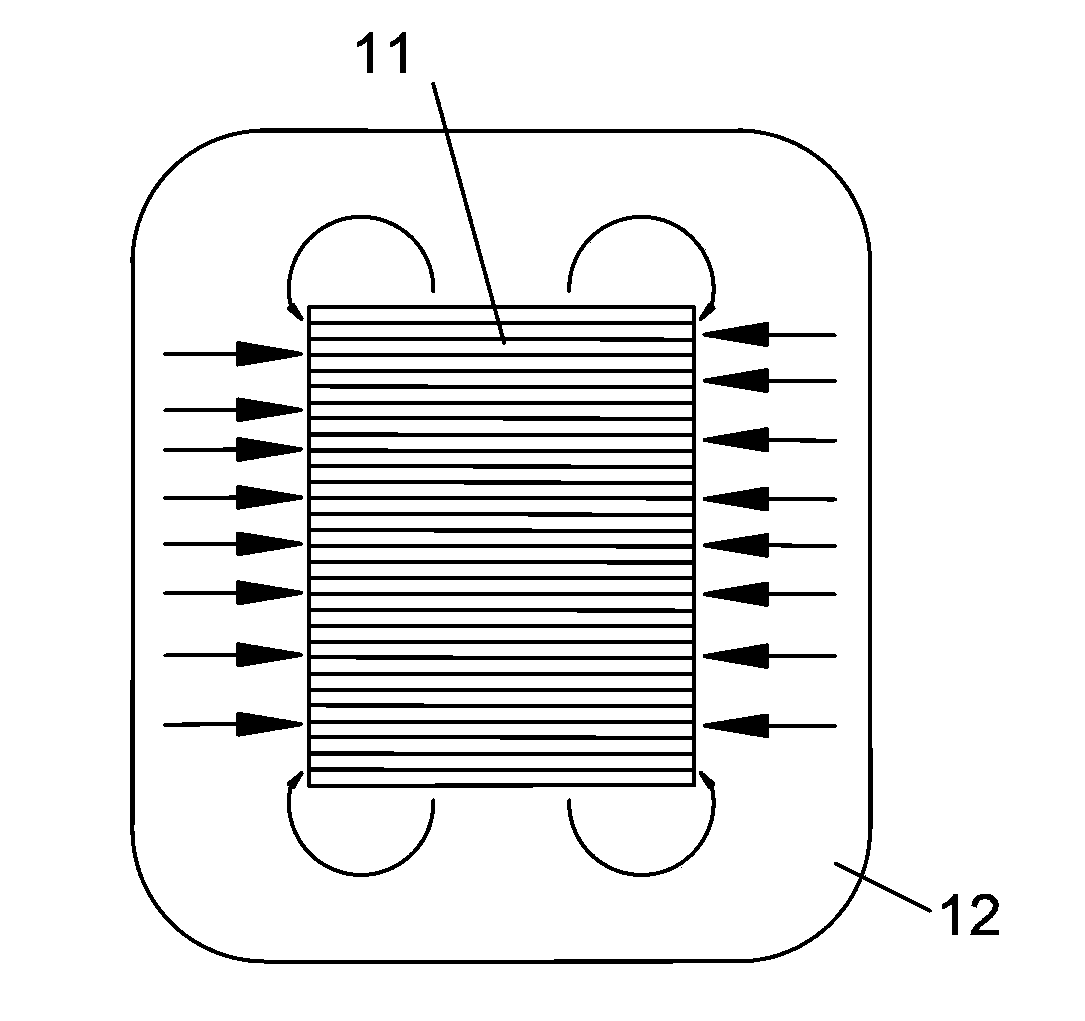

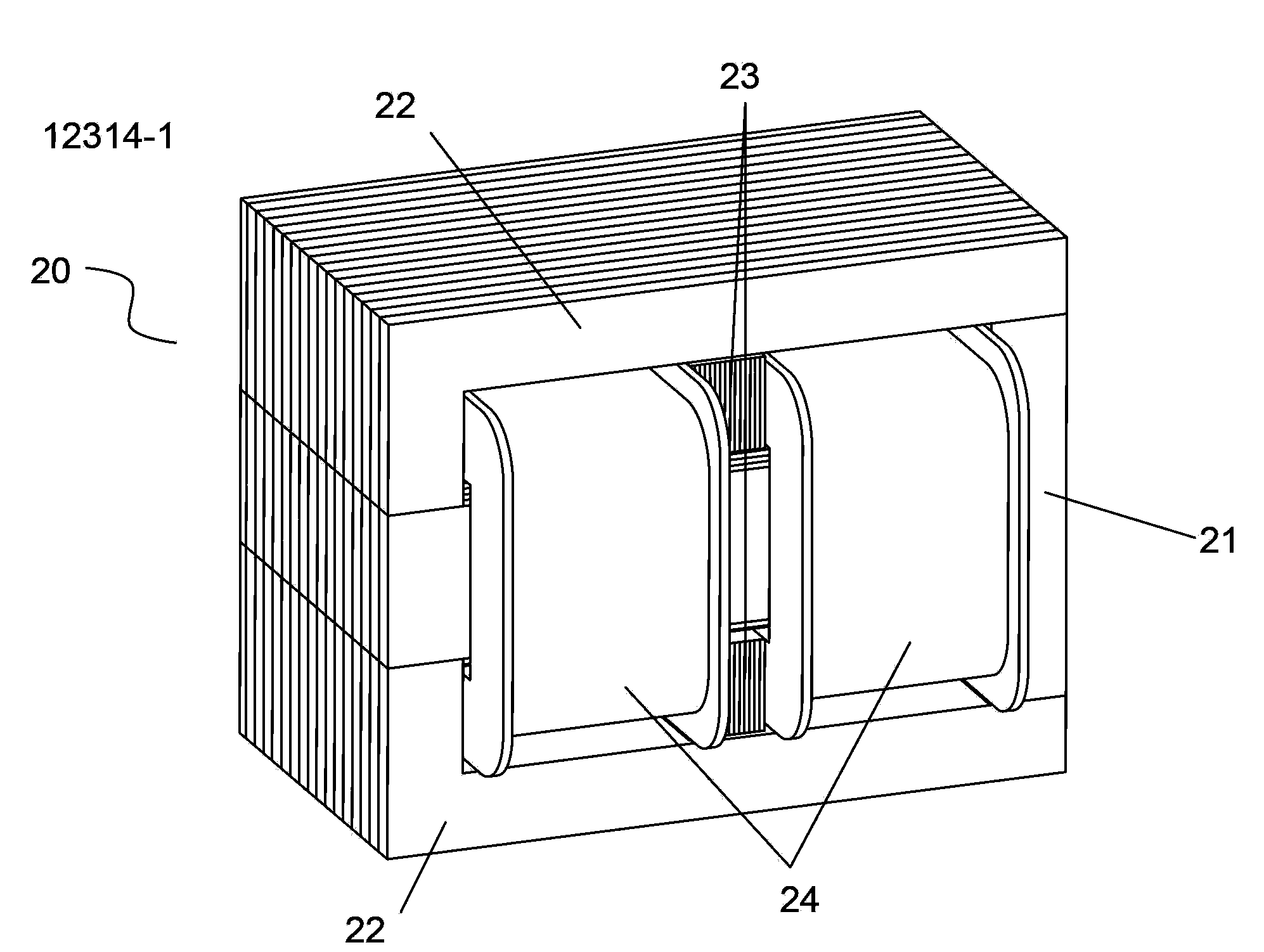

[0017] see image 3 , Figure 4 As shown, the leading peak ballast 20 of the present invention is similar to the prior art, and also includes a core post 21, an L-shaped magnetic yoke 22, an inline magnetic shunt block 23 and a wire package 24. The difference is that the The stem 21 includes a T-shaped main stem 211 with a magnetic flux leakage hole 25 and a trapezoidal auxiliary stem 212 that is separately arranged on both sides of the main stem 211 and integrally formed with it. Two L-shaped yokes 22 are symmetrically arranged on the stem 21. Two magnetic shunt blocks 23 are arranged horizontally in the two spaces formed by the splicing of the core post 21 and the L-shaped yoke 22. Road blocks 23 apart. Wherein, the entire core column 21 is formed by stacking T-shaped silicon steel sheets, and the width of the T-shaped si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com