Solar ceramic coating and manufacturing method thereof

A technology of solar energy and coating, applied in the field of solar coating, which can solve the problems of coating shedding, lower heat absorption efficiency, and lower heat absorption performance, and achieve the effects of easy replacement, increased absorption surface, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

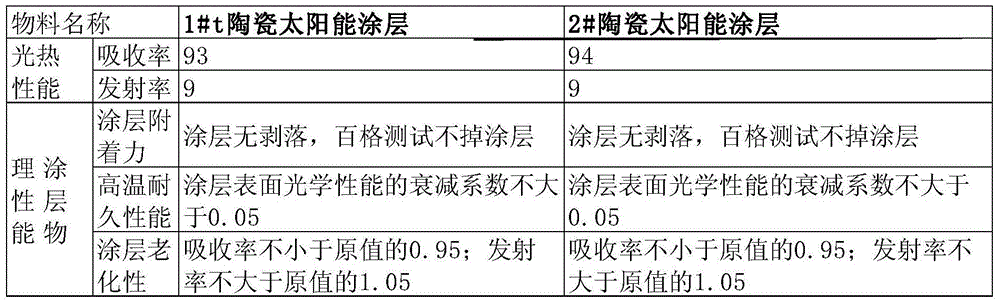

Examples

Embodiment 1-2

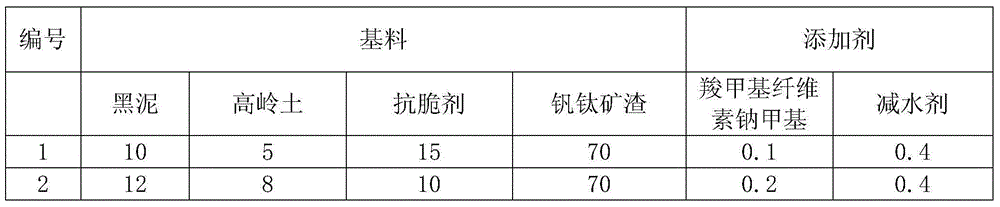

[0025] Table 1: Recipe Table

[0026]

[0027] In the above Table 1, the content of each component in the base material is the percentage by mass, and the content of the additive is the percentage by mass of the base material.

[0028] In Example 1, the preparation steps are as follows: Step 1) Weighing; According to the ratio of various raw materials in the No. 1 formula in Table 1: formula table, the raw materials are weighed;

[0029] Step 2) Mixing and crushing; add the raw materials after step 1) in proportion to 50% of the mass of the base material, and then put them into a ball mill for wet crushing and ball milling to obtain mud;

[0030] Step 3) sieve and spray dry; pass the slurry prepared in step 2) through 12 mesh, 60 mesh and 120 mesh sieves in sequence, then spray dry and granulate to obtain powder;

[0031] Step 4) Pressing, firing, and crushing: Press the powder after step 3) into a green body and dry it into a roller kiln for firing to obtain a black porce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com