Nanometer Pd/Fe catalyst and application thereof

A catalyst and nanotechnology, applied in the chemical industry, can solve the problems of agglomeration, increased material brittleness, difficult separation and recovery, etc.

Inactive Publication Date: 2014-04-02

HARBIN NORMAL UNIVERSITY

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

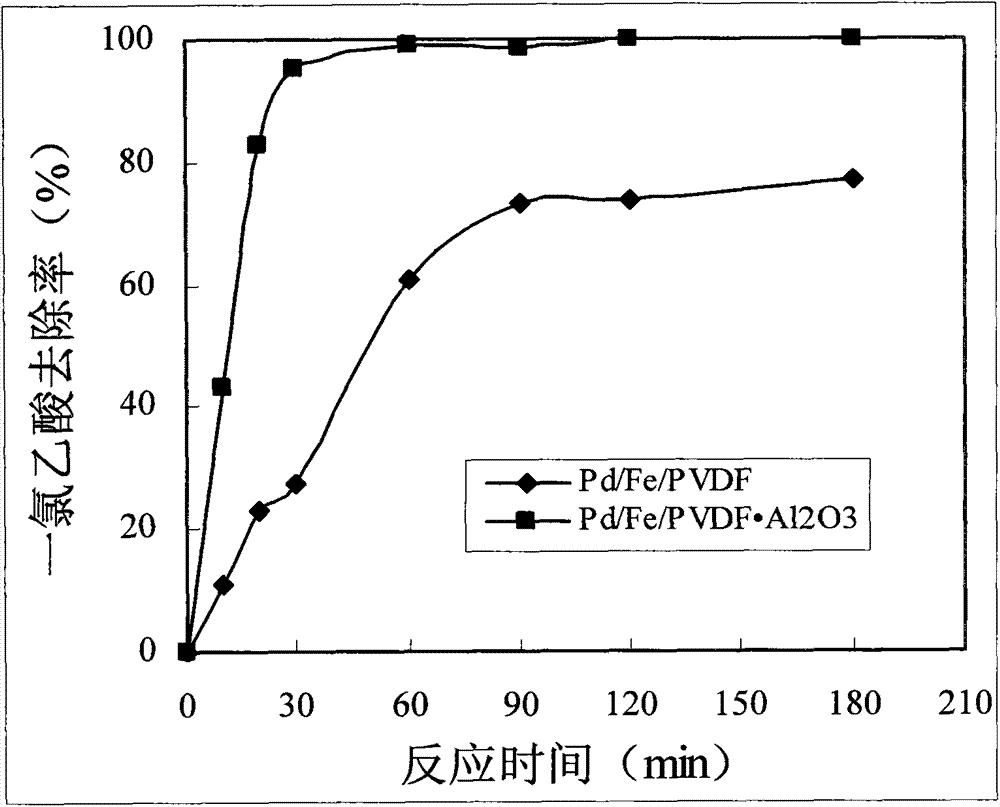

[0004] However, when the nano-Pd / Fe catalytic reducing agent is used for wastewater treatment, there are the following disadvantages: (1) If the nano-Pd / Fe catalytic reducing agent is not loaded on a suitable filler, it is easy to agglomerate; (2) after the reaction, the nano-Pd / Fe catalytic reducing agent is not easy to separate and recover from water, and will cause secondary pollution; thus, it will lead to a decrease in dechlorination efficiency

[0006] However, when PVDF is used as a filler, its application is limited due to the water repellency of the material itself. Although some researchers have modified PVDF, most of them are limited to using the purchased PVDF membrane as a filler-loaded nano-Pd / Fe catalytic reducer. And when the purchased PVDF membrane is used as a filler, it must be surface-modified to support nano-Pd / Fe catalytic reducing agent

After research, it is found that the following problems exist when the modified PVDF membrane is used as a filler: (1) After the surface modification, the mechanical strength and durability of the PVDF filler are reduced, and the brittleness of the material is increased; (2) It affects the nano-Pd / Fe (3) cannot fundamentally solve the purpose of immobilizing nano-Pd / Fe catalytic reductant and improving dechlorination efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Table 1 Carrier composition and preparation conditions

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

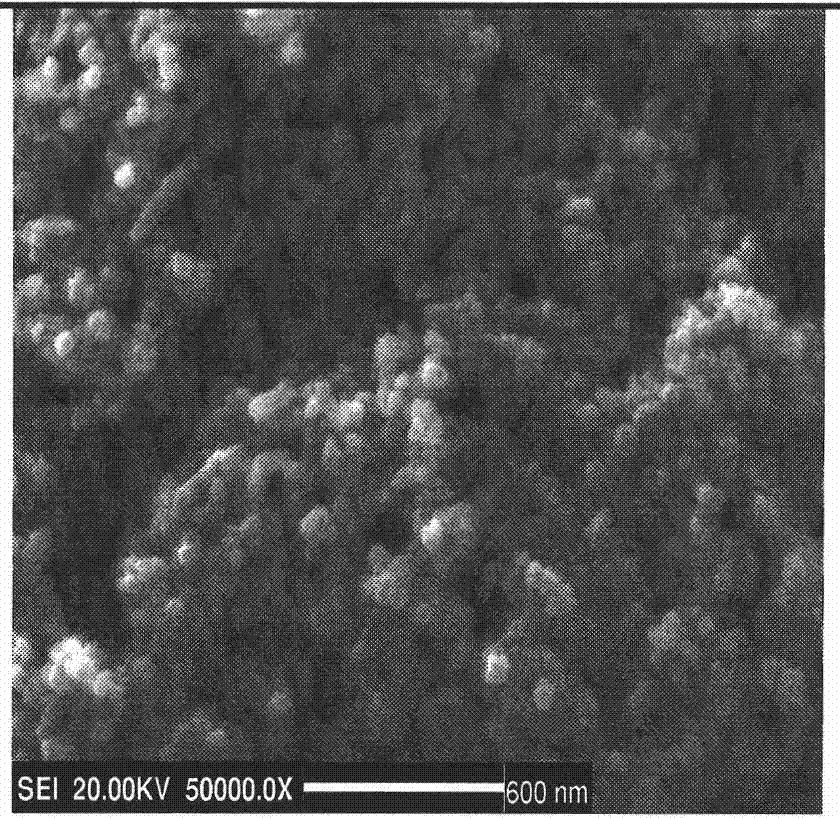

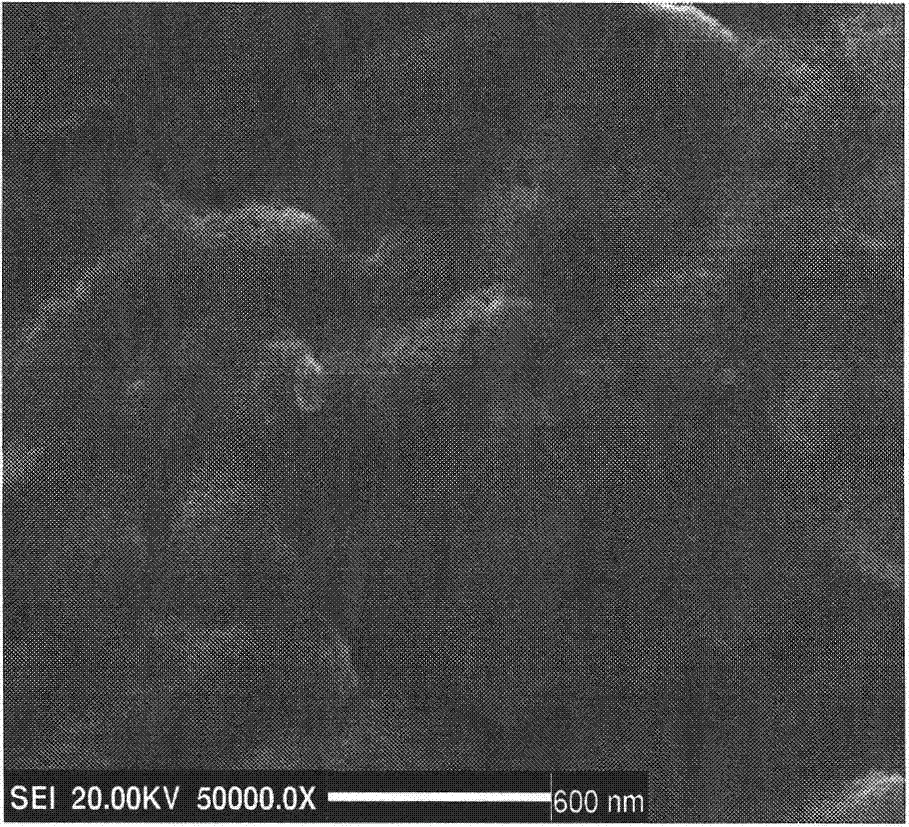

The invention discloses a nanometer Pd / Fe catalyst and an application of the nanometer Pd / Fe catalyst in catalytic dechlorination. The nanometer Pd / Fe is supported on a PVDF Al2O3 (polyvinylidene fluoride Al2O3) thin film, wherein the thin film is 0.1 to 0.3mm; every centimeter of the thin film contains 0.5 to 0.6 microgram of Fe, and the content of Pb is 0.5 to 0.6 percent of that of Fe.

Description

technical field [0001] The invention belongs to the field of chemical industry, and in particular relates to a nanometer Pd / Fe catalyst and its application in catalytic dechlorination. Background technique [0002] Nano-Pd / Fe catalytic reducing agent has a large specific surface area and high reactivity, and has the characteristics of high reactivity, fast reaction speed and complete degradation when dechlorinating organic compounds in water. It is the best choice for chlorinated organic compounds in water Good remover. Therefore, the nano-Pd / Fe catalytic reducer has broad application prospects in the field of in-situ remediation of polluted groundwater and wastewater treatment. [0003] In the process of degrading organic chlorides with nano-Pd / Fe catalytic reduction, as transition metal palladium has empty orbitals, it can form transition complexes with p electron pairs of chlorine elements in chlorine-containing organic substances or π electrons of double-bonded organic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J31/26C02F1/70C02F1/58C02F101/36

Inventor 孟昭虹臧淑英

Owner HARBIN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com