a mortar

A mortar and bowl body technology, applied in the field of mortar, can solve the problems of high labor intensity, low grinding efficiency, and impurities in the grinding process, and achieve high grinding efficiency, improved grinding efficiency, and ingenious shape and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

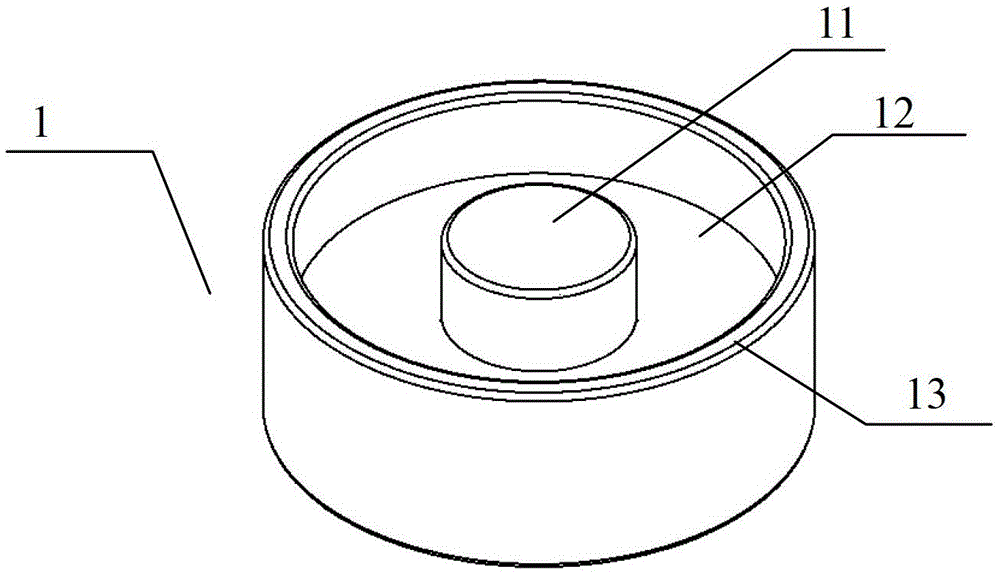

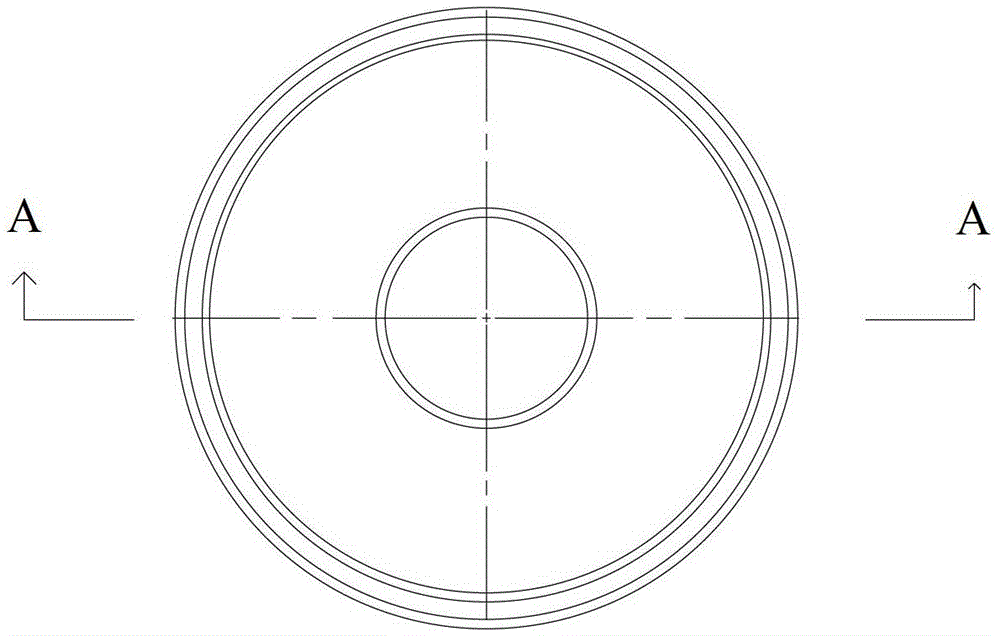

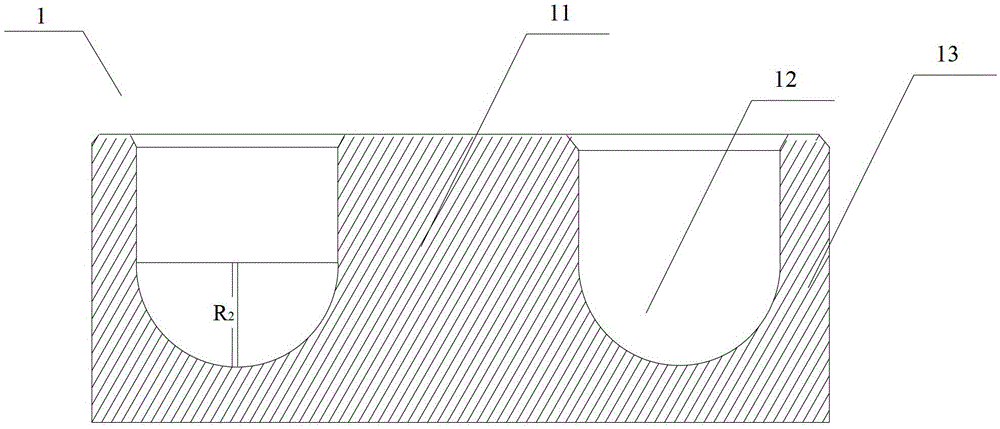

[0032] The invention provides a mortar made of corundum with a purity higher than 90% (the material of the mortar is not limited to corundum, and other wear-resistant materials such as silicon carbide and wear-resistant steel can also be used). Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, the mortar provided by the present invention includes a mortar body 1 and a mortar hammer 2, and the mortar hammer 2 includes a hammer head 21 and a hammer handle 22, and the hammer head 21 is spherical; the mortar body 1 includes a mortar body wall 13 , the middle part of the bowl 1 is provided with a cylindrical protrusion 11, and a circular track 12 is formed between the inner surface of the bowl wall 13 and the outer surface of the protrusion 11, and the bottom section of the circular track 12 is It is a downwardly concave curved surface, which is a semicircle; the curved surface is adapted to the shape of the outer surface of the hammer head 21; the rad...

Embodiment 2

[0034] The invention provides a mortar made of wear-resistant materials. Such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 As shown, the mortar provided by the present invention includes a mortar body 1 and a mortar hammer 2, and the mortar hammer 2 includes a hammer head 21 and a hammer handle 22, and the hammer head 21 is spherical; the mortar body 1 includes a mortar body wall 13 , the middle part of the bowl 1 is provided with a cylindrical protrusion 11, and a circular track 12 is formed between the inner surface of the bowl wall 13 and the outer surface of the protrusion 11, and the bottom section of the circular track 12 is It is a downwardly concave semicircular curved surface; the curved surface is adapted to the shape of the outer surface of the hammer head 21; the radius of the hammer head 21 is R 1 , the radius of the semicircular bottom of the circular track 12 is R 2 , R 2 -R 1=0.01mm. When the spherical hammer head 21 is grinding in the ...

Embodiment 3

[0036] The invention provides a mortar made of ceramics. Such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, the mortar provided by the present invention includes a mortar body 1 and a mortar hammer 2, and the mortar hammer 2 includes a hammer head 21 and a hammer handle 22, and the hammer head 21 is spherical; the mortar body 1 includes a mortar body wall 13 , the middle part of the bowl 1 is provided with a cylindrical protrusion 11, and a circular track 12 is formed between the inner surface of the bowl wall 13 and the outer surface of the protrusion 11, and the bottom section of the circular track 12 is It is a downwardly concave semicircular curved surface; the curved surface is adapted to the shape of the outer surface of the hammer head 21; the radius of the hammer head 21 is R 1 , the radius of the semicircular bottom of the circular track 12 is R 2 , R 2 -R 1 =0.2mm. When the spherical hammer head 21 is grinding in the circular track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com