Special automatic welding equipment for hydraulic oil cylinder with high right-angle oil nozzle locating accuracy

A hydraulic cylinder and automatic welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor positioning stability, poor welding quality, and low welding efficiency of right-angle nozzles, and achieve good welding effect, The effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

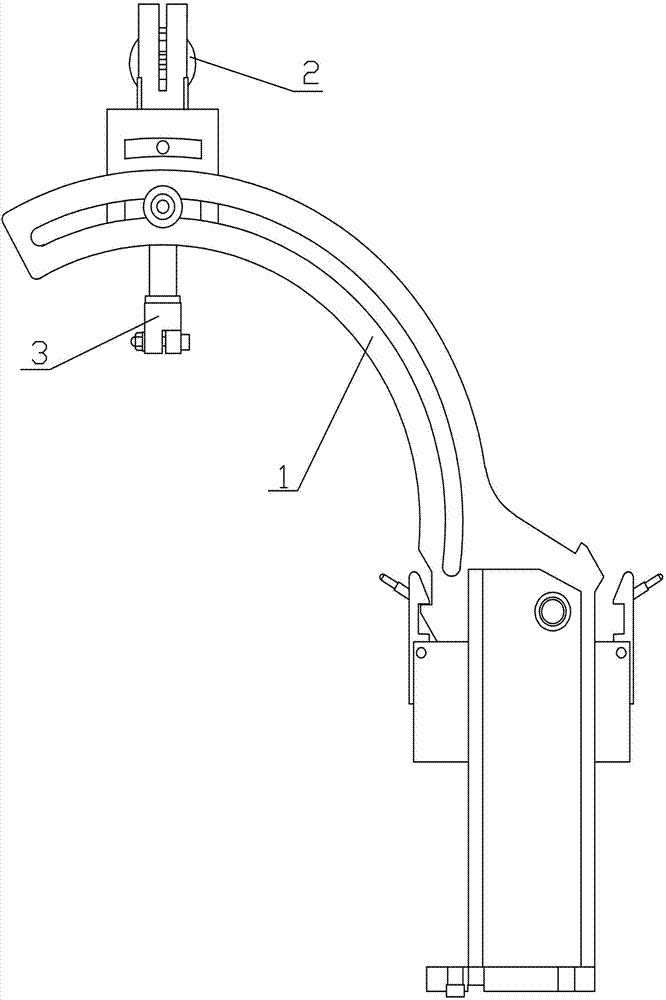

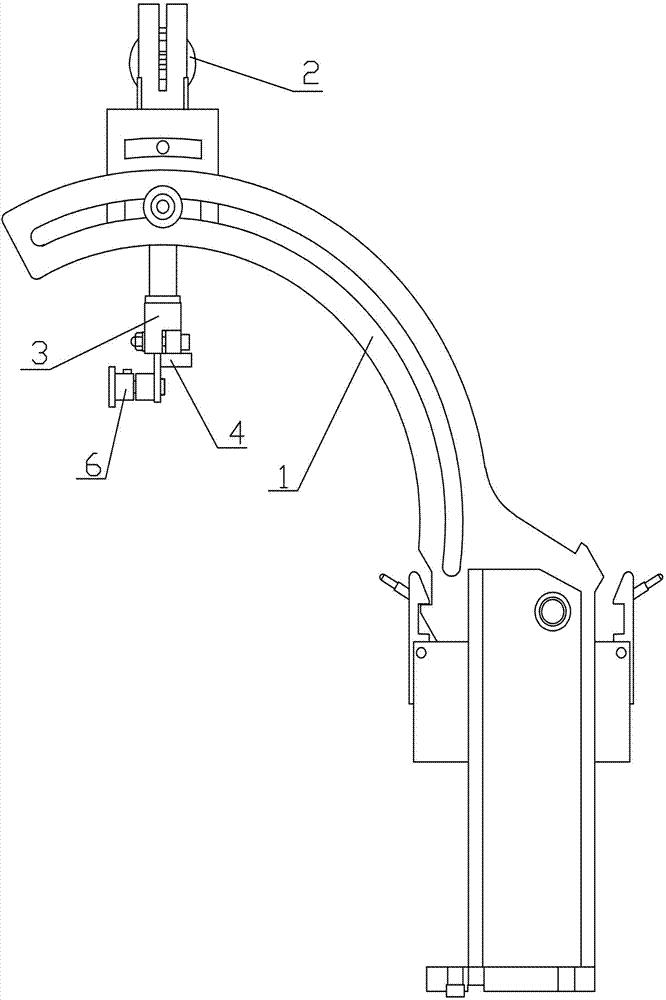

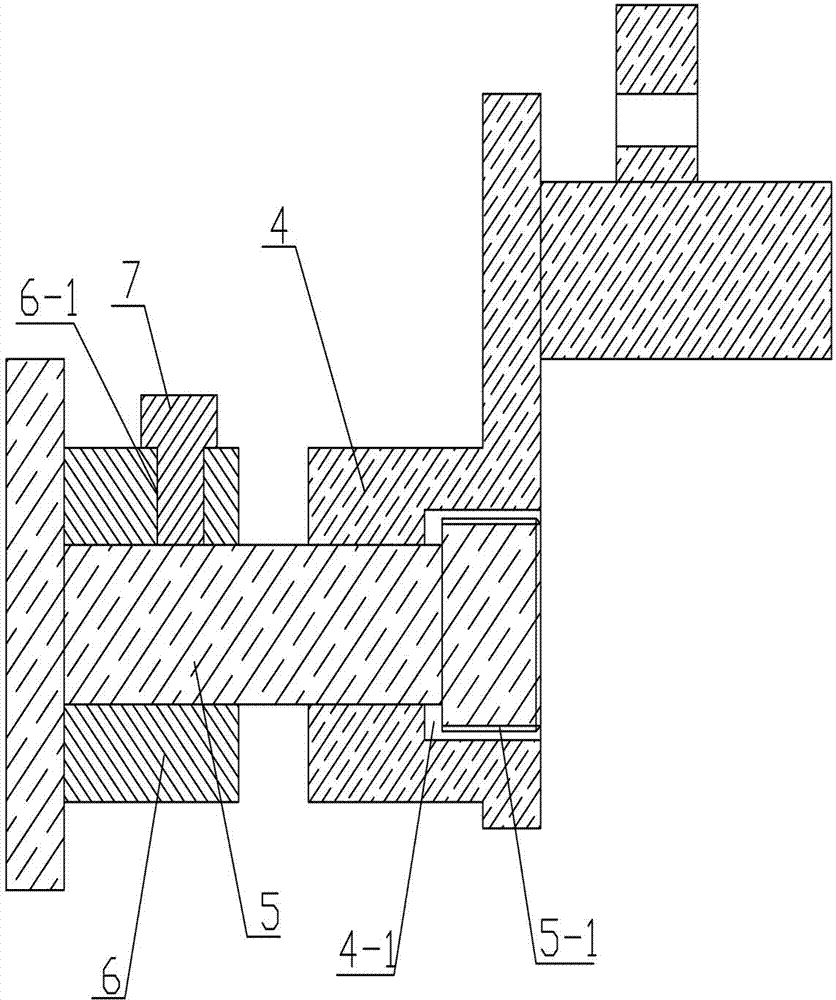

[0013] Such as figure 2 and image 3 As shown, the special automatic welding equipment for hydraulic oil cylinders with high positioning accuracy of right-angle oil nozzles provided by the present invention includes a rapid oil nozzle positioning tool 1 installed on the special automatic welding equipment for hydraulic oil cylinders, and a pressure arm 3 is provided on the oil nozzle rapid positioning tool 1. The lower end of the pressing arm 3 is connected with a right-angle reversing seat 4, and the right-angled reversing seat 4 is provided with a stepped hole 4-1, and the axis of the stepped hole 4-1 is perpendicular to the moving direction of the pressing arm 3, A straight rod 5 runs through the above-mentioned stepped hole 4-1, the outer diameter of the straight rod 5 matches the smaller diameter of the stepped hole 4-1, and the outer surface of one end of the straight rod 5 is distributed with a right-angle oil nozzle. The external thread 5-1 matched with the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com