Manufacturing method of elevator gear blank

A manufacturing method and a technology of gears, which are applied in the field of manufacturing elevator gear blanks, can solve the problems of low production efficiency, difficulty in guaranteeing internal quality, and poor appearance quality of casting methods, and achieve easy quality control, reduced energy consumption, and small cutting allowances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

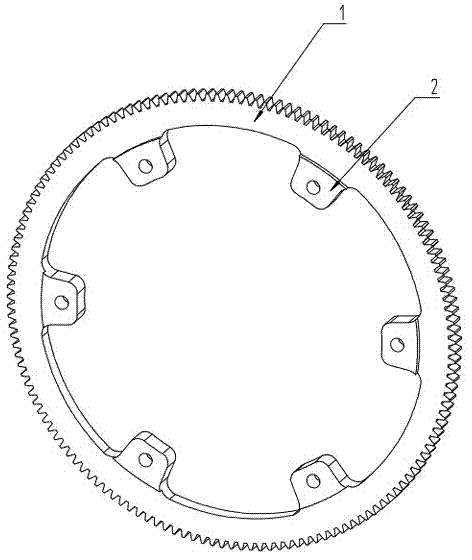

[0009] The outer ring 1 and strap 2 of the elevator gear are processed separately. The processing method of outer ring 1 is: round steel blanking → forging → reaming → reverse welding groove; the processing method of strap 2 is: round steel blanking → die forging forming →Inverted welding groove; then weld the outer ring and the strap into one body, and then normalize.

[0010] Outer ring 1 and strap 2 use 20#~35# steel with good welding performance. According to the weight of the finished product, calculate the blanking size of round steel and accurately blank the material. The outer ring 1 and both sides of the gear have only 2~3mm machining allowance. The forging margin is too large.

[0011] The secondary forging is used to refine the crystal grains and the die forging is used to make the inner hole and the tap 2 of the gear do not need gold processing to meet the requirements of the design drawing. During the processing of the outer ring 1 metal, light clamping is required to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com