Plane fixture and method for machining box fault isolator

A technology for processing boxes and fixtures, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of destroying the processing positioning position, affecting the processing accuracy, and high labor intensity, achieving simple production and replacement, adaptability Wide range of capabilities, the effect of simplifying the clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

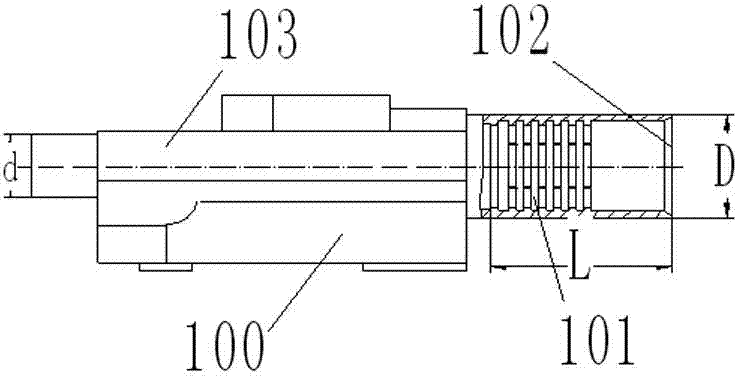

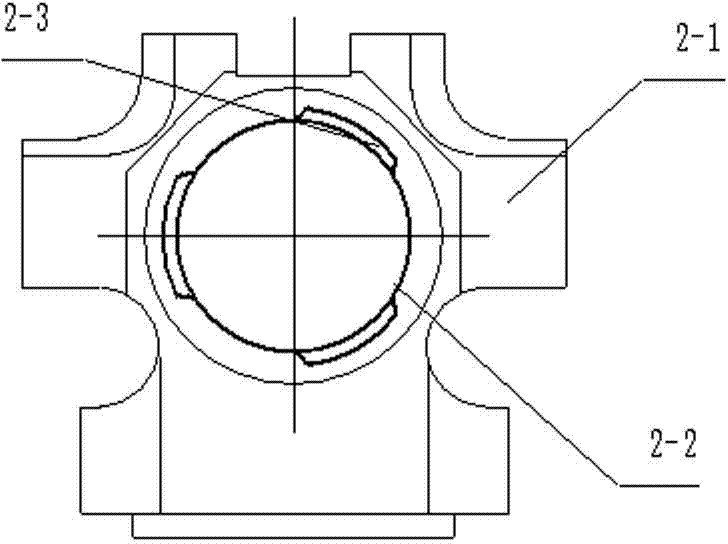

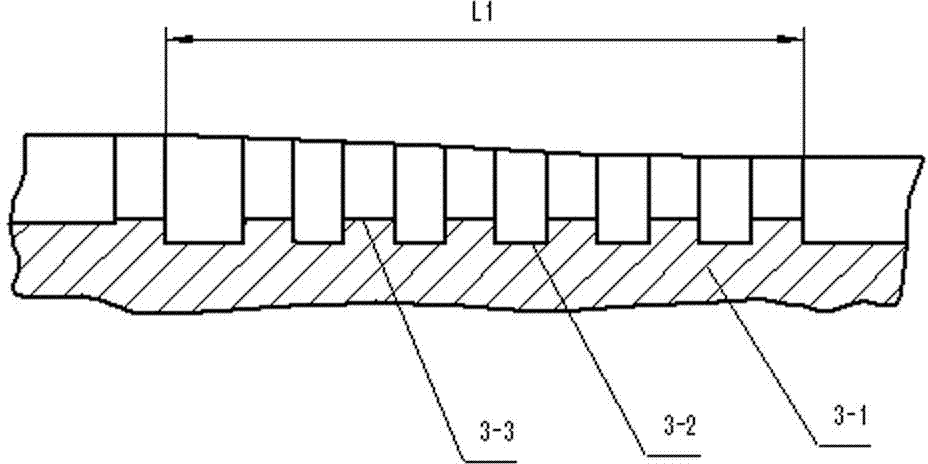

[0056] see Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the planing jig for box partition processing of the present invention includes a jig bottom plate 4-1: a part is installed on the right end of the jig bottom plate 4-1, and the other part is installed on the right side of the indexing mechanism 8 and is connected with the installation The positioning clamping mechanism 6 corresponding to a part on the right end of the clamp base plate 4-1, the indexing mechanism 8 installed on the left end of the clamp base plate 4-1, the positioning clamping mechanism 6 and the indexing mechanism 8 and the transmission mechanism 7 installed on the clamp bottom plate 4-1, and the profiling mechanism 9 located outside the left side of the indexing mechanism 8;

[0057] From Figure 4 and Figure 6 It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com