Ship seawater filter

A seawater and ship technology, applied in gravity filters, filtration and separation, chemical instruments and methods, etc., can solve problems such as increasing equipment maintenance difficulty, increasing equipment costs, and using more space, reducing work complexity and maintenance difficulty. The effect of reducing the size of the equipment and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

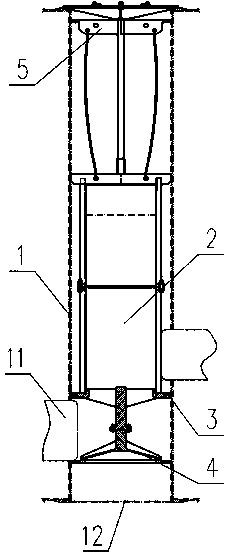

[0014] Such as figure 2 As shown, a seawater filter for a ship includes seawater wells 1 arranged on both sides of the ship. The sidewall and bottom of the seawater well 1 are respectively provided with a high-level water inlet 11 and a low-level water inlet 12. A filter for filtering water is installed in the seawater well 1. Cartridge 2, on the inner wall of the seawater well 1 above the high-level water inlet 11, a filter cartridge seat 3 supporting the filter cartridge 2 is provided, and the lower end of the filter cartridge 2 is detachably connected with a closing cover plate that closes the low-level water inlet 12 4. The top end of the filter cartridge 2 is connected with a lifting device 5 for lifting the filter cartridge 2 out of the seawater well 1 .

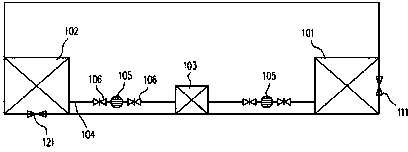

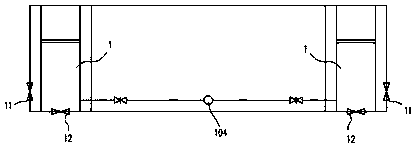

[0015] Such as image 3 Shown is a schematic diagram of the installation of a seawater filter for a ship. Two seawater filters are installed on both sides of the ship and supplied with water through the water supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com