Belt Break Protection System for Belt Conveyors

一种皮带输送机、保护系统的技术,应用在输送机物件、输送机控制装置、运输和包装等方向,能够解决托辊横飞、损伤托辊支架、胶带劳动强度大等问题,达到结构科学合理、工作性能可靠、附加价值高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

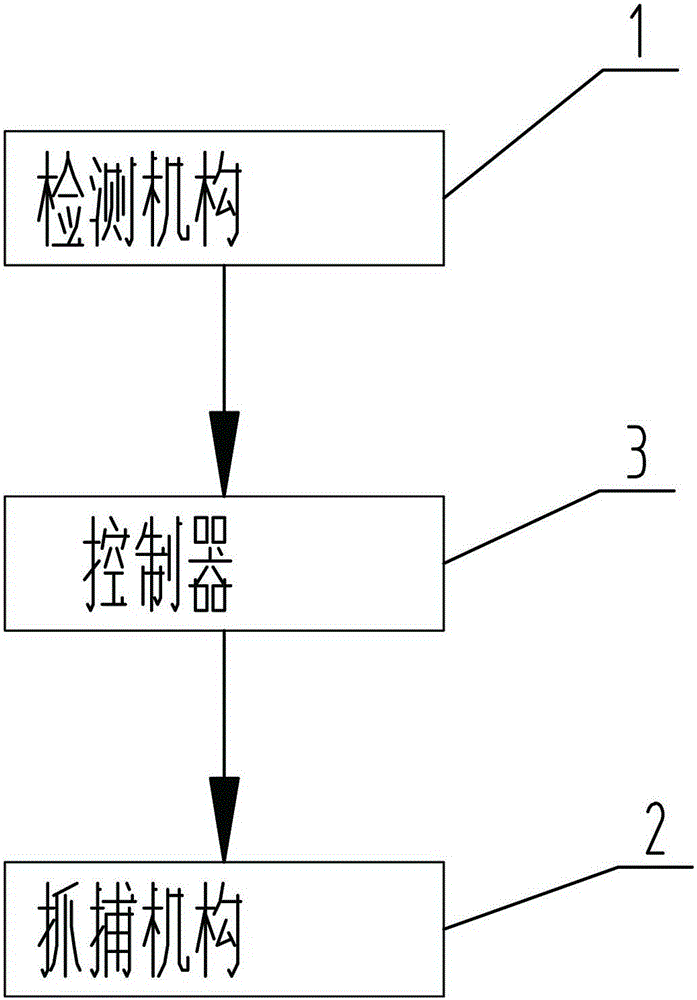

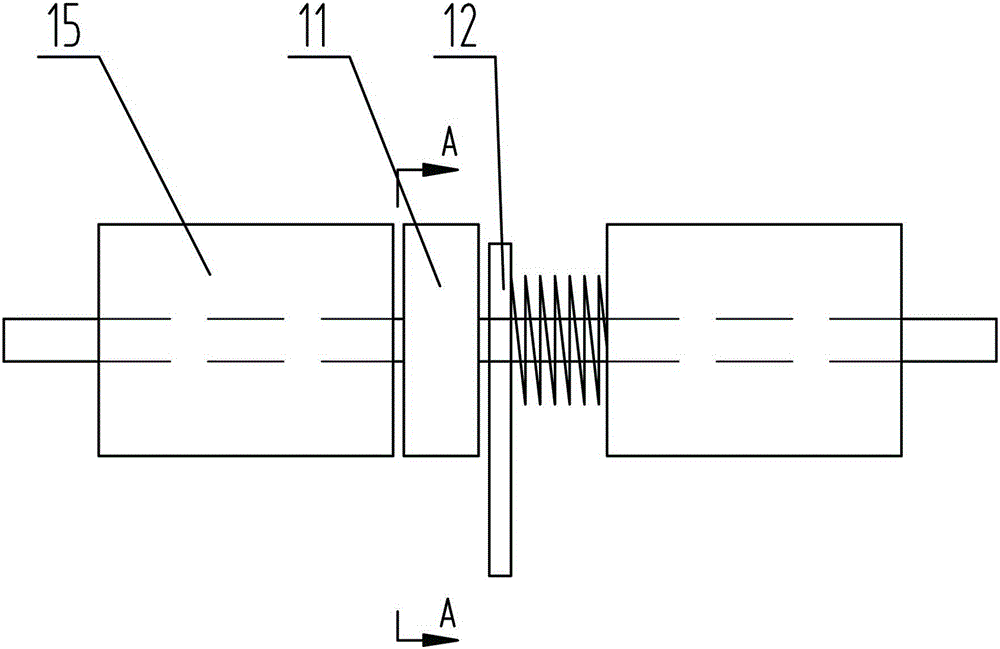

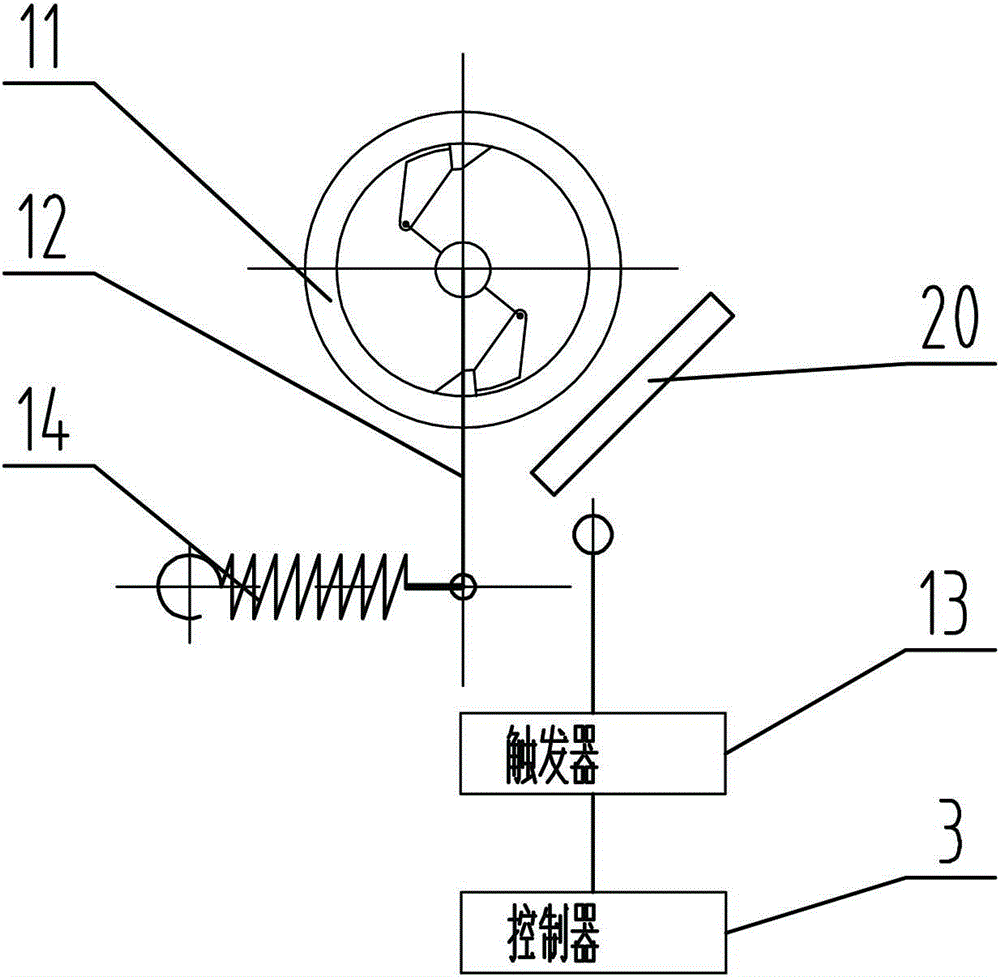

[0036] like Figures 1~11 As shown in the figure, a broken belt protection system for a belt conveyor includes a detection mechanism 1, a capture mechanism 2, a controller 3 and a capture installation frame 4. The detection mechanism 1 is installed at the middle idler of the belt conveyor to capture The installation frame 4 is installed on the belt conveyor, the capture mechanism 2 is installed on the capture installation frame 4, the detection mechanism 1 and the capture mechanism 2 are respectively connected to the controller 3 through the data cable, and the detection mechanism 1 detects the broken belt and sends a signal to the The controller 3, the controller 3 controls the capture mechanism 2 to capture the broken tape. The capture mechanism 2 includes a main body 5, the main body 5 is arranged on the capture installation frame 4, the main body 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com