Evaporation equipment and its evaporation method

A kind of equipment and evaporation technology, which is applied in the direction of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of small nozzle clogging, limit the maximum injection rate of the injection mechanism, and increase the failure rate of the injection mechanism evaporation equipment and other issues to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be further described below in conjunction with the drawings and embodiments. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

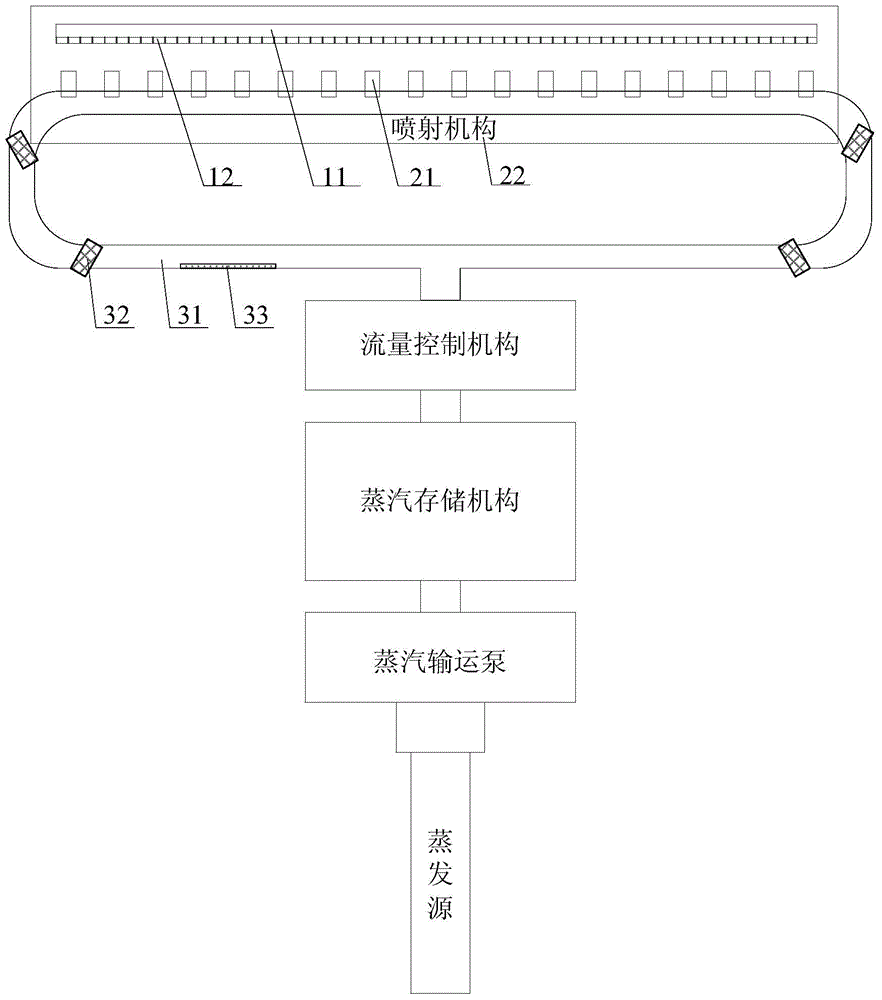

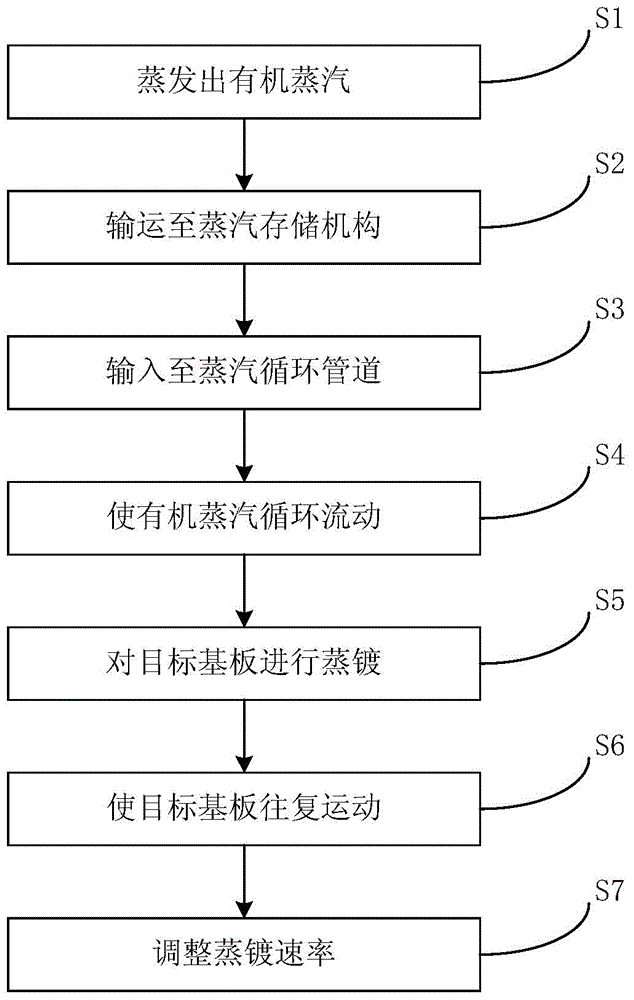

[0031] The evaporation equipment provided in this embodiment is as figure 2 shown in; the evaporation equipment includes an evaporation source, a steam circulation mechanism and an injection mechanism; wherein, the evaporation source is used to provide organic vapor; the steam circulation mechanism is used to circulate the organic vapor provided by the evaporation source; the injection mechanism and the steam cycle The mechanism is connected, and is used for spraying the organic vapor in the steam cycle mechanism onto the substrate 11 to form an organic coating. In this evaporation equipment, the organic vapor provided by the evaporation source is circulated by using the steam circulation mechanism, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com