Debris flow drainage channel of steel cable net bottom protection type and its application and construction method

A steel cable net and drainage channel technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of the bottom damage of drainage channels, high maintenance costs in the later period, and inability to use normally. The effect of reducing post-maintenance costs and improving project reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

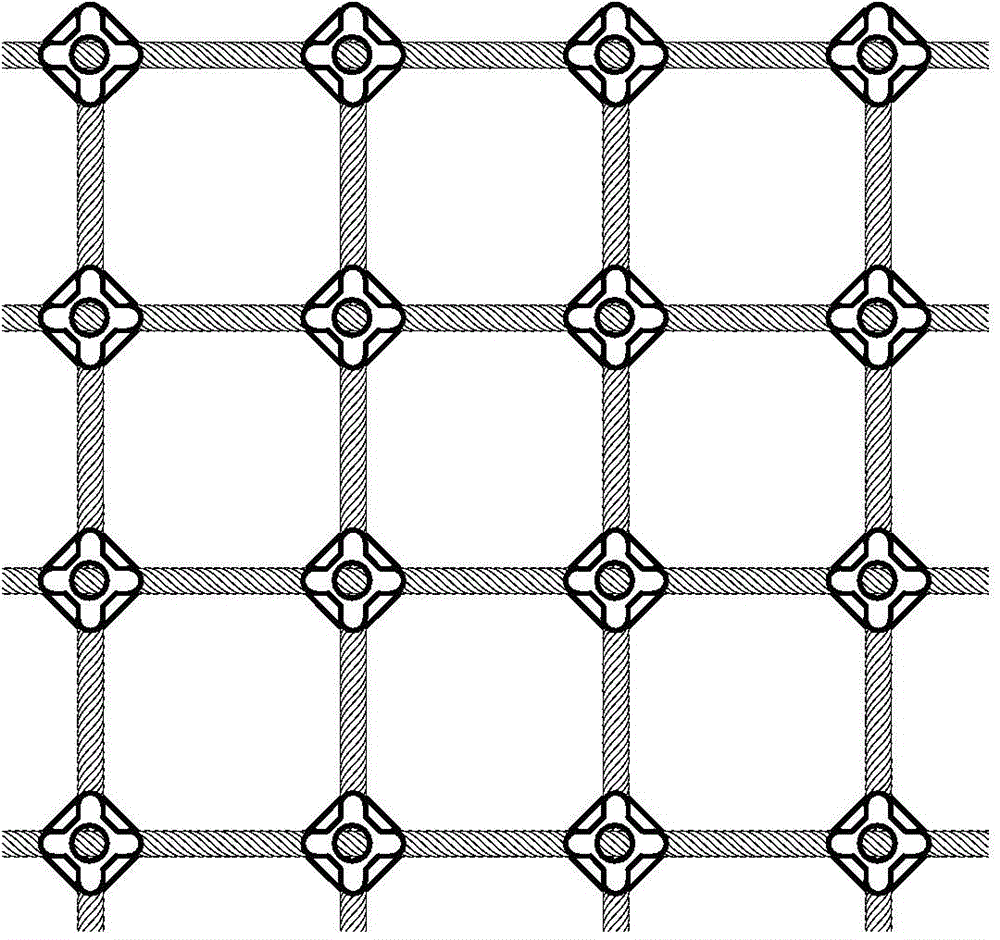

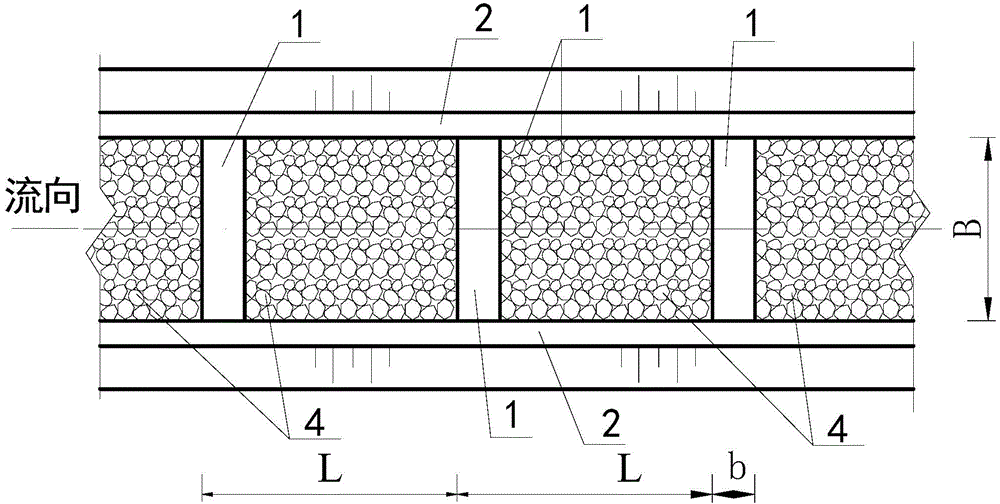

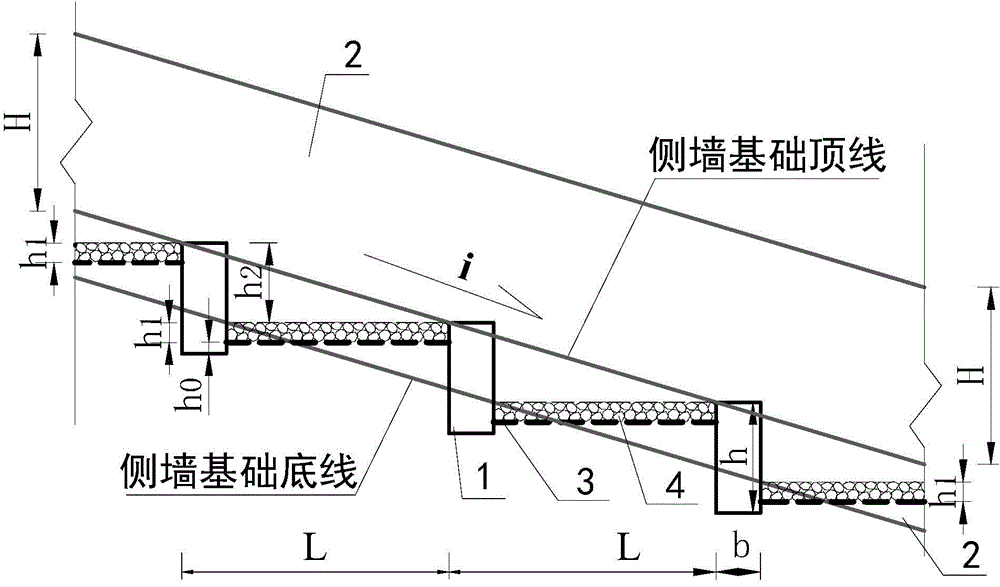

[0029] Such as figure 1 , figure 2 , image 3 shown. The drainage area of a debris flow ditch is 1.86km 2 , in order to control debris flow disasters, it is planned to set up 2 sand-retaining dams in the middle of the basin, and build a 400m drainage channel on the accumulation fan. For the drainage channel, the vertical gradient i of the trench bed at the bottom of the channel is 0.35, and the discharge flow rate of debris flow is 98m 3 / s, bulk density 21kN / m 3 , in order to control the strong abrasion and erosion of debris flow, a steel cable net bottom protection type debris flow drainage channel is used. The steel cable net bottom protection type debris flow drainage trough includes the transverse penetrating rib sill 1 at the bottom of the trough arranged at a certain distance and the side walls 2 of the drainage trough on both sides, and steel cables are arranged between the adjacent upstream and downstream rib sills 1 Net 3 bottom protection, the steel cables ...

Embodiment 2

[0036] Such as figure 1 , figure 2 , image 3 shown. The drainage area of a debris flow ditch is 9.52km 2 , in order to control debris flow disasters, it is planned to set up 4 sand-retaining dams in the middle of the basin, and build a drainage channel of 560m on the accumulation fan. For the drainage channel, the vertical gradient i of the trench bed at the bottom of the channel is 0.15, and the discharge flow rate of debris flow is 278m 3 / s, bulk density 16kN / m 3 , in order to control the strong abrasion and erosion of debris flow, a steel cable net bottom protection type debris flow drainage channel is used. The steel cable net bottom protection type debris flow drainage trough includes the transverse penetrating rib sill 1 at the bottom of the trough arranged at a certain distance and the side walls 2 of the drainage trough on both sides, and steel cables are arranged between the adjacent upstream and downstream rib sills 1 Net 3 bottom protection, the steel cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com