Spray maintenance method and system for wall structure

A technology of wall structure and maintenance system, which is applied in building structure, processing of building materials, construction, etc. It can solve the problems of not keeping water spray equipment for a long time, wasting water resources, and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

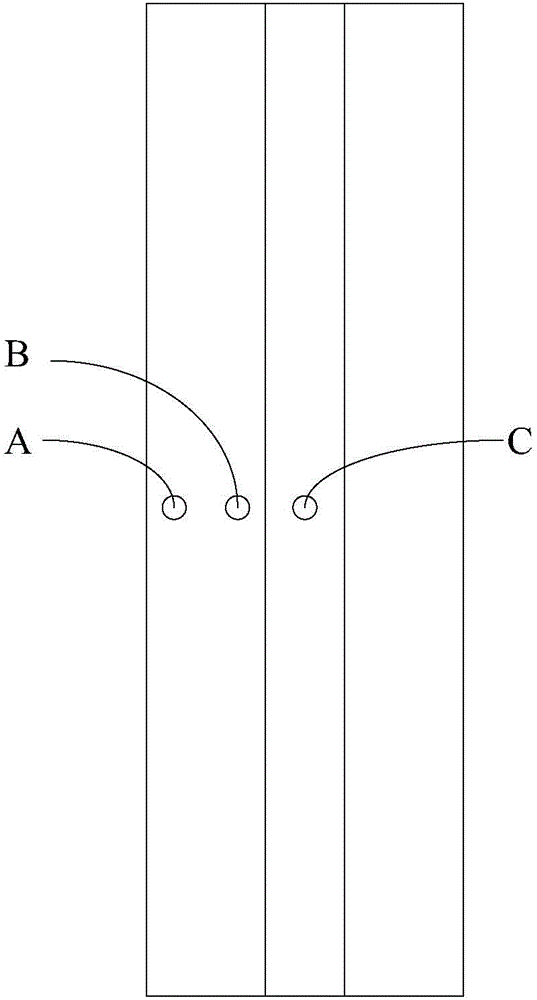

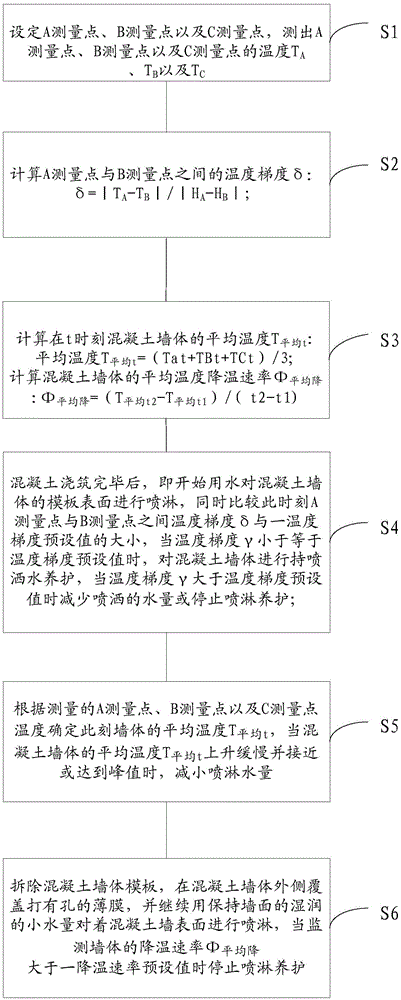

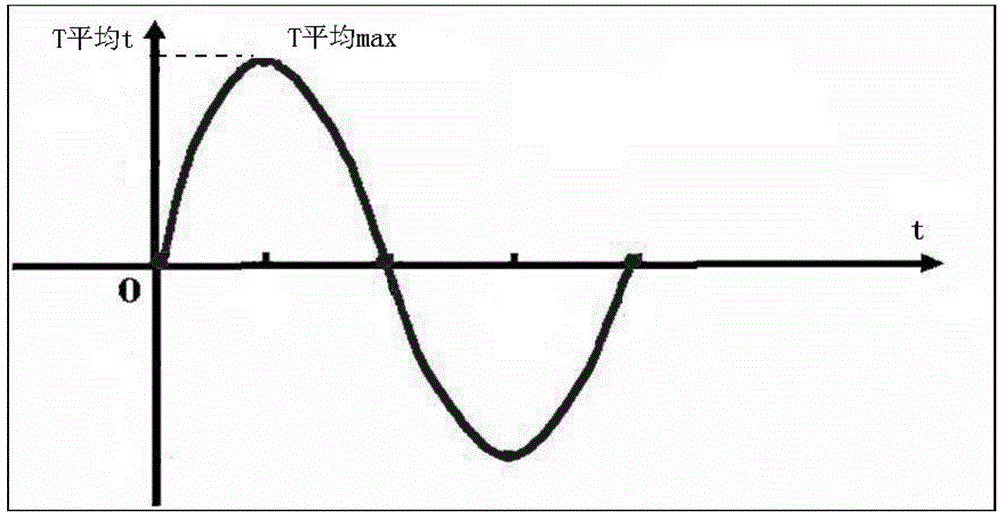

[0036] combine figure 1 as shown, figure 1 It is a schematic diagram of the measurement positions of points A, B and C of the concrete wall, figure 2 A flow chart of the maintenance method for the concrete wall structure.

[0037] Such as figure 1 and figure 2 As shown, in the first embodiment, the present invention provides a concrete wall structure maintenance method, comprising the following steps:

[0038] S1. Pouring to form a concrete wall and spraying water on the formwork clamped on the concrete wall after the concrete is poured, and setting three measurement points in the concrete wall structure, respectively marked as: A measurement point, B measurement point and C measurement point,

[0039] Timely measure the temperature values of A measurement point, B measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com